NI PXI Chassis Design Advantages

Contents

Overview

Acting as the central structure of a PXI system, the chassis is comparable to a PC’s enclosure and motherboard. It supplies power, cooling, a communication bus, and all of the instruments within it. Moreover, it also provides the timing, triggering, and synchronization capabilities that make PXI so powerful for automated testing applications. NI chassis feature high-performance backplanes and a rugged, reliable mechanical package. Available in sizes ranging from two to 18 slots, you can find the right NI chassis for your application whether you need a portable, benchtop, rack-mount, or embedded system. NI PXI Express chassis are compatible with PXI Express, PXI, CompactPCI Express, and CompactPCI modules. In this paper, learn about the following NI design features that enhance performance and reliability over other chassis available on the market:

- Cooling performance—NI chassis exceed PXI Express cooling requirements—and many chassis can provide 58 W or 82 W of cooling for high-performance modules.

- Acoustics—Designed to minimize acoustic emissions for your desktop or lab to reduce the amount of electrical noise (EMI) transmitted to the PXI modules for sensitive measurements.

- Power supplies—NI PXI chassis power supplies are custom-designed, and NI maintains design ownership for dependability and serviceability across the entire operating temperature range and AC input range with no power derating.

- Timing and synchronization—High-performance clock, bus, and trigger features simplify timing at different levels of precision and synchronization to multiple time bases spanning single chassis to complex multi-chassis architectures.

Cooling

Each PXI chassis has a variety of different slots: the system slot, used for the embedded controller, peripheral slots, used for PXI Express modules, and hybrid slots which are used for PXI or PXI Express modules. The PXI Express specification (defined by the PXI Systems Alliance) requires a minimum of 30 W of power available to each peripheral slot but does not make specific requirements about cooling the modules. Other vendors’ PXI chassis may meet minimum power specifications; in reality, they can have dramatically different power and cooling performance because of specific design choices, such as fan position. Although these vendors claim the ability to power and cool greater than 82 W, that’s not true for every slot, and often requires the chassis adhere to limiting or difficult-to-achieve caveats.

The latest generation NI PXI Express chassis are designed and validated to meet or exceed the cooling requirements for the most power-demanding PXI modules by delivering at least 58 W of cooling to each slot within a PXI chassis. Its cooling capacity allows for maximum flexibility in how your instruments can be placed within in your chassis.

Additionally, some NI PXI chassis push slot cooling capacity even further and can provide 82 W of cooling to a single slot, enabling advanced capabilities of high-performance modules, such as digitizers, high-speed digital I/O, and RF modules, in applications that may require continuous acquisition or high-speed testing. PXI chassis can vary in total power available, so it is always best practice to perform a system-level power budget when configuring a new system. NI’s top-tier PXI Express chassis will support full power and cooling without power budgeting.

NI chassis can support a chassis filled entirely of higher-power instruments that include the following types of modules:

- NI PXI Digital Pattern Instruments

- NI PXI 300 W Power Supplies

- NI PXI 300 W Electronic Loads

- NI PXI Vector Signal Transceivers

- NI PXI High-Speed Serial Instruments

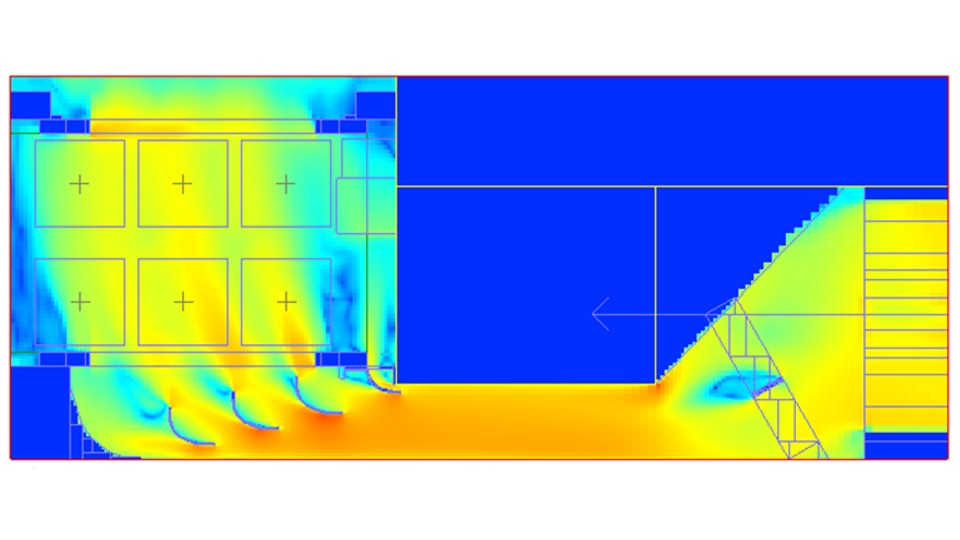

Figure 1: NI PXIe-1095 chassis features the patented rear cooling fan design.

Many NI PXI chassis feature a patented rear cooling fan design, as depicted in Figure 1, where air from the rear of the chassis (2) is forced through a turning vane and evenly distributed across all module slots (1). The design provides increased cooling and fewer stagnant spots in airflow compared to chassis designs where the fans are located directly underneath the modules. Fans at the rear of the chassis also help reduce the amount of electrical noise from the fans’ motors that the modules are subjected to.

NI also offers slot blockers—plastic modular filler PXI cards that can be populated in unused slots of the chassis. The slot blockers enhance the airflow in populated slots by reducing airflow bypass in the empty slots, resulting in a reduction of the temperature rise of electronic components on installed modules by up to 20 percent.

These design advantages help NI PXI chassis achieve improved cooling performance when compared to other major vendors, which is evaluated by measuring the average component temperature difference of the components on a PXI module inserted into the chassis, (min-max). In a benchmark evaluation, the NI PXIe-1095 chassis delivered 4.6 °C superior cooling performance on the 58 W high fan setting (5,200 RPM at 55 °C ambient temp).

Acoustics

Even with their advanced cooling performance capabilities, NI PXI chassis are designed to minimize overall system acoustic emissions. These are important considerations, as PXI systems are used in both rack-mounted automated test and benchtop validation environments, where acoustic emission requirements differ. Combining fan speed control, the type of fan used, and fan mounting method make cooling optimization possible while minimizing the acoustic noise emitted.

Many NI PXI chassis permit you to select between two fan speeds, high or auto, by using a fan speed selection switch. When set to auto, the chassis fan speed is controlled proportionally to the ambient air temperature as read at the chassis fan inlet. Below a reading of 30 °C, the chassis cooling system operates in an acoustic performance zone, where acoustic emissions are minimized. As the measured ambient temperature rises above 30 °C, the chassis cooling fan speed is increased accordingly. When the fan speed is set to high, the chassis provides maximum air flow independent of the ambient temperature; this mode is most appropriate for applications where acoustical noise is not of concern.

| Fan Speed | Sound Pressure Level [dBA]* | ||||

|---|---|---|---|---|---|

| NI PXIe-1084** | NI PXIe-1095** | NI PXIe-1092 | NI PXIe-1088 | NI PXIe-1083 |

Auto (up to 30 °C) | 34.4 | 37.7 | 35.9 | 44.3 | 48.4 |

High | 55.0 | 56.6 | 55.7 | 59.0 | 61.9 |

* Sound pressure level is defined at operator position in accordance with ISO 7779

** 38 W cooling profile mode only; higher cooling profiles have a higher sound pressure level

Table 1: Compare the sound pressure level of PXI Express chassis.

NI implements pulse-width modulated (PWM) fans in many of its PXI chassis to reduce acoustic emissions further than traditional voltage-controlled fans. PWM signal control of the fan permits the NI chassis designer to use a wider range of the fan’s RPM settings, thus making it possible to fine-tune the chassis’ acoustic emissions and cooling performance.

To meet (and exceed) the cooling requirements of the PXI specification, the fans selected for implementation within an NI PXI chassis must be powerful. Many NI chassis use fan mounts that are manufactured of vibration dampening materials to isolate the chassis frame from mechanical vibration in the fans, further reducing the acoustic noise. In many NI PXI chassis, these mounts, and thus the fans, are placed in the rear, helping to reduce the amount of electrical noise (EMI) transmitted to the PXI modules.

NI PXI chassis are designed to minimize the overall system acoustic emissions and can do so while delivering advanced cooling performance. Noted in Table 2, some chassis fans have been further optimized for benchtop performance, such as the PXIe-1084 in its 38 W cooling mode. Note that 10 dB here translates to a perceived noise difference of 2X.

Power Supplies

The PXI platform specifications, as defined by the PXI Systems Alliance, require that an 18-slot PXI Express chassis deliver 650 W of power on the 3.3 V, 5 V, and +12 V backplane rails to power the system controller and module slots. It is important when comparing PXI chassis from different vendors to do so using the “power supplied to the backplane” (or similar) specification, and not just the total power or power per slot. NI makes sure to realistically and consistently define power specifications whether it is total power, power supplied to backplane, or power per slot. Other vendors often market misleading power specifications that cannot be achieved under typical installation/operation environments.

In its product documentation, NI specifies the total power available to the modules from the chassis power supply. In contrast, many other vendors list the output of the power supply. By subtracting the power consumed by the chassis components such as the fans and backplane from the total power from the power supply, NI documentation specifies the usable power available for the controller and modules. NI PXI chassis manuals clearly indicate the current on each voltage rail and the maximum power dissipation per slot.

Unlike other PXI vendors on the market, NI maintains design ownership of the instrument-grade power supplies in many of its eight to 18-slot PXI and PXI Express chassis. As a result, NI can guarantee long-term availability of these power supplies and fewer design changes to its chassis due to power supply manufacturer changes. In contrast, other PXI vendors who rely solely on a standard PC power supply have little to no control over the quality of their power supplies.

The instrument-grade power supplies implemented within NI PXI chassis are optimized to meet the unique power requirements of PXI as opposed to power supplies designed for general use in personal computers. NI’s power supplies are custom-designed for NI chassis to meet and exceed the PXI specification minimum power requirements. With these power supplies, for example, NI high-performance PXI Express chassis can deliver at least 82 W to all chassis slots.

| Voltage | Slot | Current Provided | |

|---|---|---|---|

| PXI-5 Min. Spec | NI High-Performance PXI | ||

| +12 V | System | 11 A | 20 A |

| Peripheral | 2 A | 6 A | |

| Hybrid | 2 A | 6 A | |

| +3.3 V | System | 9 A | 9 A |

| Peripheral | 3 A | 3 A | |

| Hybrid | 3 A | 3 A | |

| +5 V | System | 9 A | 9 A |

| Peripheral | – | – | |

| Hybrid | 2 A | 2.5 A | |

| -12 V | System | – | – |

| Peripheral | – | – | |

| Hybrid | 0.25 A | 0.25 A | |

Table 2: NI PXI Express chassis are designed to exceed PXI specification for minimum current per slot.

For systems where high availability is a concern, NI has designed easy-to-replace power supplies and fans for some of its nine-slot and higher chassis. In the event of a power supply failure, the user can replace the power supply from the rear by sliding out/in the failed/replacement power supply after removing the screws that secure it in place. Similarly, the user can replace the main fans from the rear of the chassis by removing the panel screws, disconnecting the existing fan panel, connecting the replacement fan panel, and replacing the panel screws. The design facilitates a mean time to repair (MTTR) of the power supply to less than five minutes. If the chassis is implemented in a rack-mount installation, as long as the back of the chassis is accessible, you can replace the power supply and rear fans without removing modules or reconnecting any I/O. Check product specifications to determine which chassis support this feature.

As NI PXI chassis implement instrument-grade power supplies, they are capable of providing the minimum power requirement over the entire specified operating temperature range (0 °C to 50–55 °C) with no power derating. Power derating refers to the loss in power supplied to the chassis slots when operated at higher temperatures or other extreme environmental specifications. Many other vendors’ PXI chassis meet the required PXI specification for available power at lower ambient operating temperatures (20 °C to 35 °C) but may become unstable or inoperable at higher temperatures (>40 °C). To reiterate, with an NI PXI chassis you can operate a chassis filled with modules at the highest temperature specified on the data sheet (please refer to product manuals for operating temperature ranges for specific NI PXI chassis models). NI power supplies also provide full power over the entire universal AC input range of 100 VAC to 240 VAC whereas competitor chassis may derate heavily for the low-line portion of this range.

The electrical noise generated by moving mechanical features within the chassis, specifically cooling fans, can degrade the measurement accuracy of PXI and PXI Express peripheral modules. To prevent this, many NI chassis not only place cooling fans in the rear of the chassis but also implement a dedicated 12 V power supply to power the chassis cooling fans, system controller slot, and in some cases the power supply fans, to avoid coupling noise from these components into the rails powering the measurement modules.

Most NI chassis also feature remote sensing of the output voltage on the backplane power rails, to compensate for voltage drops. Remote sensing is a design feature important for PXI and PXI Express chassis particularly for applications with high-power modules, as it provides better regulation at the backplane when there are large load swings.

Timing and Synchronization Quality

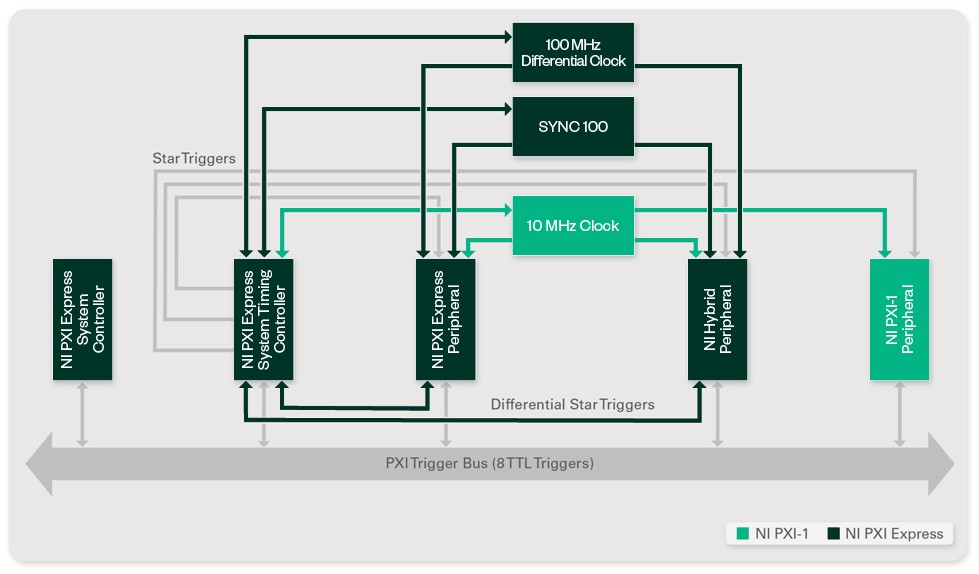

A key advantage of a PXI system is the integrated timing and synchronization capabilities. A PXI chassis incorporates a dedicated 100/10 MHz system Reference Clock (PXI_CLK10 and PXIe_CLK100) that is distributed to each slot with low skew, an eight-line PXI trigger bus connecting to every slot, and a system timing slot providing star and differential star triggers to the peripheral slots.

Figure 2: PXI Express timing and synchronization features are key advantages.

With the optional timing and synchronization upgrade, timing and synchronization features of some NI PXI chassis can be further enhanced. The PXIe-1095 and PXIe-1092 can be upgraded with an OCXO for increased frequency stability of PXI_CLK10 and PXIe_CLK100, the capability to import and automatically lock to an external 10 MHz Reference Clock, export a 10 MHz Reference Clock, and import and export the PXI trigger bus. For more about how NI PXI timing and synchronization features make it easier to build high-performance, complex, and scalable solutions, see NI PXI Timing and Synchronization Design Advantages.

NI PXI chassis offer the following features:

- Up to 24 GB/s system bandwidth and 8 GB/s per-slot of dedicated bandwidth

- Up to 82 W per slot of power and cooling for more advanced I/O modules

- Size options ranging from two to 18 slots

- Hybrid slots for instrumentation flexibility; compatibility with PXI, PXI Express, CompactPCI, and CompactPCI Express modules

| Selection Guide | Model | Part Number | Chassis Power-Supply Type | Max System Bandwidth | Slot Cooling Capacity | System Timing Slot | Onboard Clock Type | Slot Count | External Clocking | External Trigger Access |

|---|---|---|---|---|---|---|---|---|---|---|

| Low Cost, Small Form Factor Chassis, Older-Generation | PXIe-1071 | 781368-01 | AC | 3 GB/s | 38 W | — | VCXO | Total: 4 Hybrid: 3 PXI Express: 0 | — | — |

| PXIe-1073 | 781163-01 | AC | 250 MB/s | 38 W | — | VCXO | Total: 5 Hybrid: 3 PXI Express: 2 | — | — | |

| PXIe-1090 | 787040-01 | AC | 2 GB/s | 58 W | — | VCXO | Total: 2 Hybrid: 1 PXI Express: 1 | ✓ | — | |

| PXIe-1083 | 787026-01 | AC | 2 GB/s | 58 W | — | VCXO | Total: 5 Hybrid: 5 PXI Express: 0 | — | — | |

| Entry-Level, Cost-Competitive, Medium Cooling Capacity | PXIe-1082DC | 782946-01 | DC | 8 GB/s | 38 W | ✓ | VCXO | Total: 8 Hybrid: 4 PXI Express: 3 | ✓ | — |

| PXIe-1084 | 784058-01 | AC | 4 GB/s | 58 W | — | VCXO | Total: 18 Hybrid: 17 PXI Express: 0 | — | — | |

| 786397-01 | ✓ | ✓ | ||||||||

| PXIe-1085 | 783588-01 | AC | 24 GB/s | 38 W | ✓ | VCXO | Total: 18 Hybrid: 16 PXI Express: 1 | ✓ | — | |

| PXIe-1086 | 781720-01 | AC | 12 GB/s | 38 W | ✓ | VCXO | Total: 18 Hybrid: 16 PXI Express: 1 | ✓ | — | |

| PXIe-1086DC | 787137-01 | DC | 12 GB/s | 38 W | ✓ | VCXO | Total: 18 Hybrid: 16 PXI Express: 1 | ✓ | — | |

| PXIe-1088 | 784782-01 | AC | 8 GB/s | 58 W | — | VCXO | Total: 9 Hybrid: 8 PXI Express: 0 | — | — | |

| Highest Performance, Newest-Generation, Highest Cooling Capacity | PXIe-1092 | 784781-01 | AC | 24 GB/s | 82 W | ✓ | VCXO | Total: 10 Hybrid: 7 PXI Express: 0 | — | — |

| 786991-01 | OCXO | ✓ | ✓ | |||||||

| PXIe-1095 | 783882-01 | AC | 24 GB/s | 82 W | ✓ | VCXO | Total: 18 Hybrid: 5 PXI Express: 11 | — | — | |

| 785971-01 | OCXO | ✓ | ✓ |

Table 3: PXI Chassis Options and Configurations.

In conclusion, NI PXI chassis deliver exceptional performance and reliability, making them a critical component for high-performance and high-power automated testing. With superior cooling capabilities that exceed PXI Express specifications, these chassis can support high-power modules and ensure optimal thermal management. Custom-designed power supplies guarantee stable and consistent power delivery, which is crucial for maintaining the accuracy and precision of your tests. NI PXI chassis are engineered to provide superior performance and reliability to help meet the needs of your testing environment.