Configure a Measurement in FlexLogger™ Software

Overview

Innovations in engineering design are driving the continual need to quickly integrate and synchronize new sensors and industrial protocols to validate electromechanical components and systems. With sensor-specific configuration workflows, FlexLogger provides straightforward I/O setup, analysis, and logging of a mix of analog sensor measurements and CAN measurements.

Contents

- Introduction

- Set Up Analog Measurements With CompactDAQ Hardware

- Record CAN Data

- Create Calculated Channels

- Additional Resources

Introduction

FlexLogger is application software used to build customizable, scalable data-logging systems with the wide breadth of CompactDAQ hardware. Use FlexLogger with CompactDAQ to acquire analog measurements like temperature, pressure, voltage, strain, and force along with CAN messages. This means that you can use FlexLogger to acquire, view, and log all test data to a single file. You can also customize screens to view and alarm the most important measurements before and during a test.

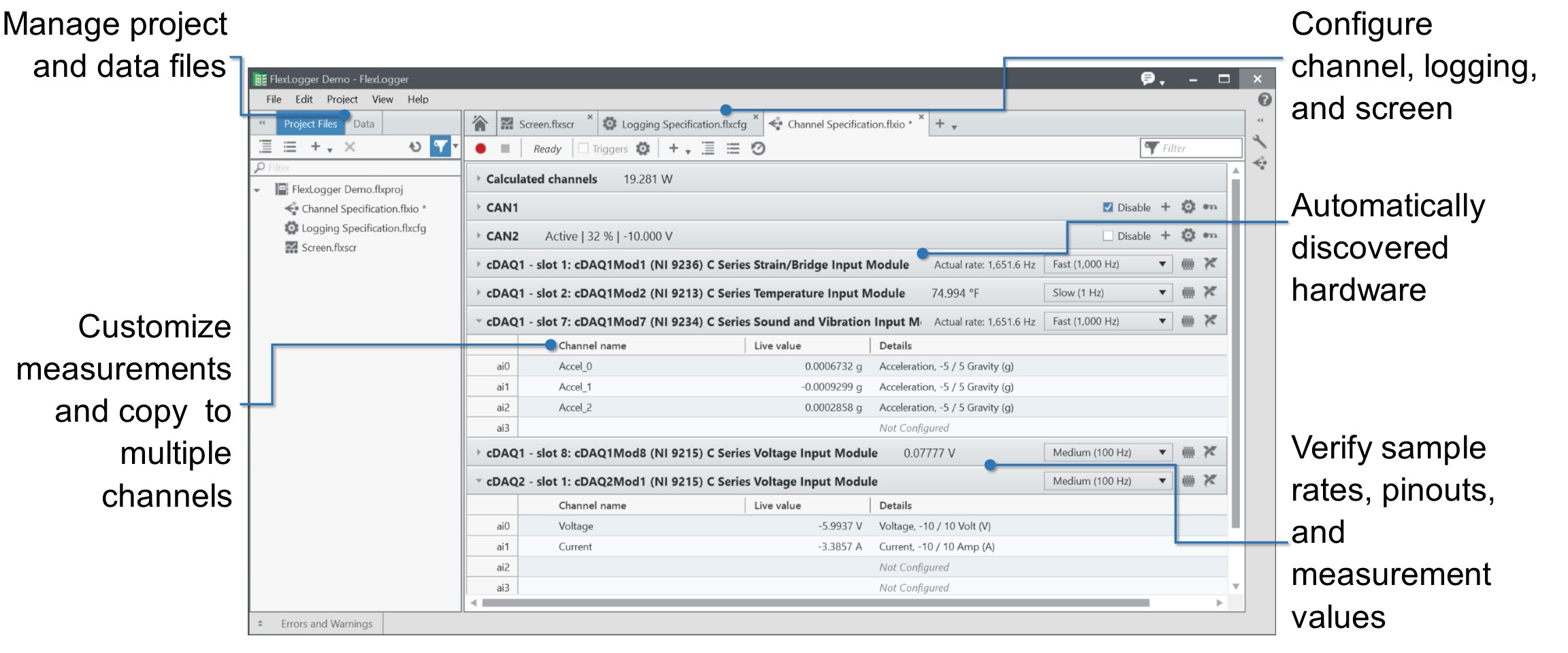

Figure 1: View Configured Measurements in FlexLogger

Set Up Analog Measurements With CompactDAQ Hardware

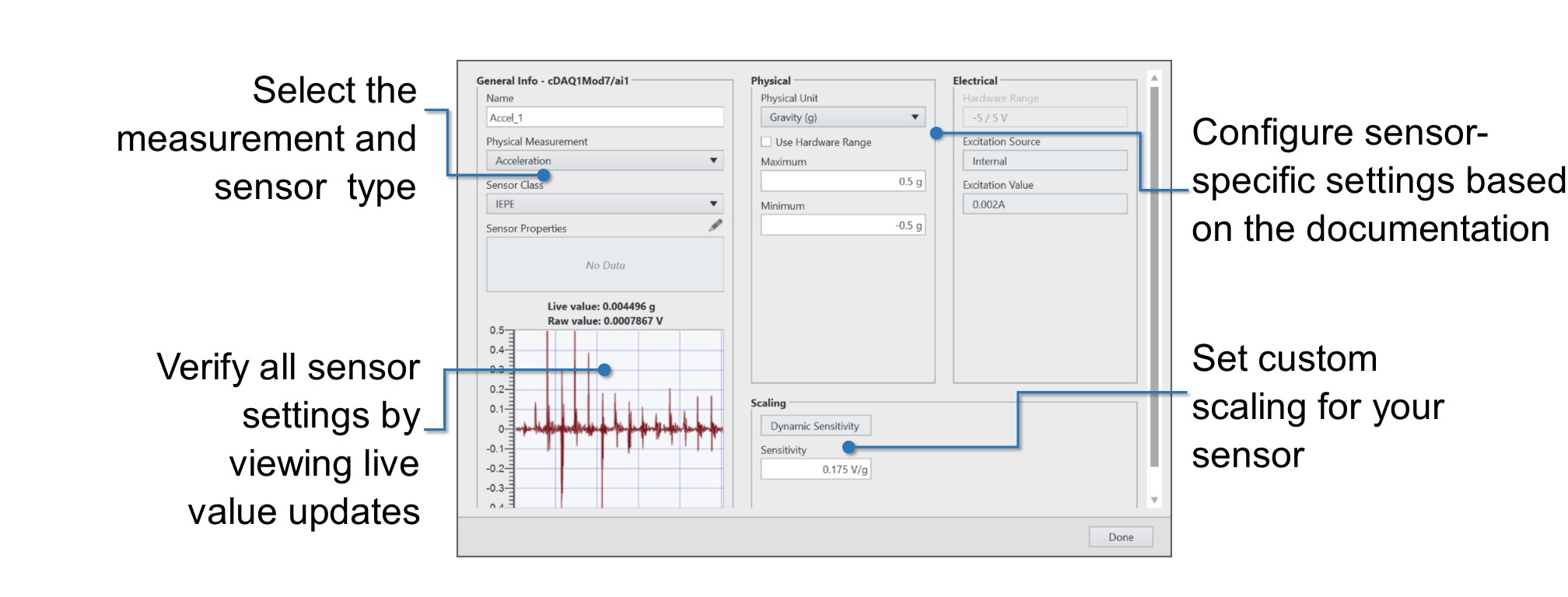

Configuring mixed measurements in FlexLogger is intuitive. When FlexLogger discovers the connected hardware, you can select any channel from the Channel Specifications table and set up your system of mixed measurements, including analog sensors, digital pulse frequency, calculations, and CAN communication. Quickly configure your measurement using the exact settings that match your physical measurement and sensor type. Verify your sensor connectivity in real time with live data previews and integrated device pinouts.

Figure 2: Configure a Vibration Measurement in the General Info Window

Record CAN Data

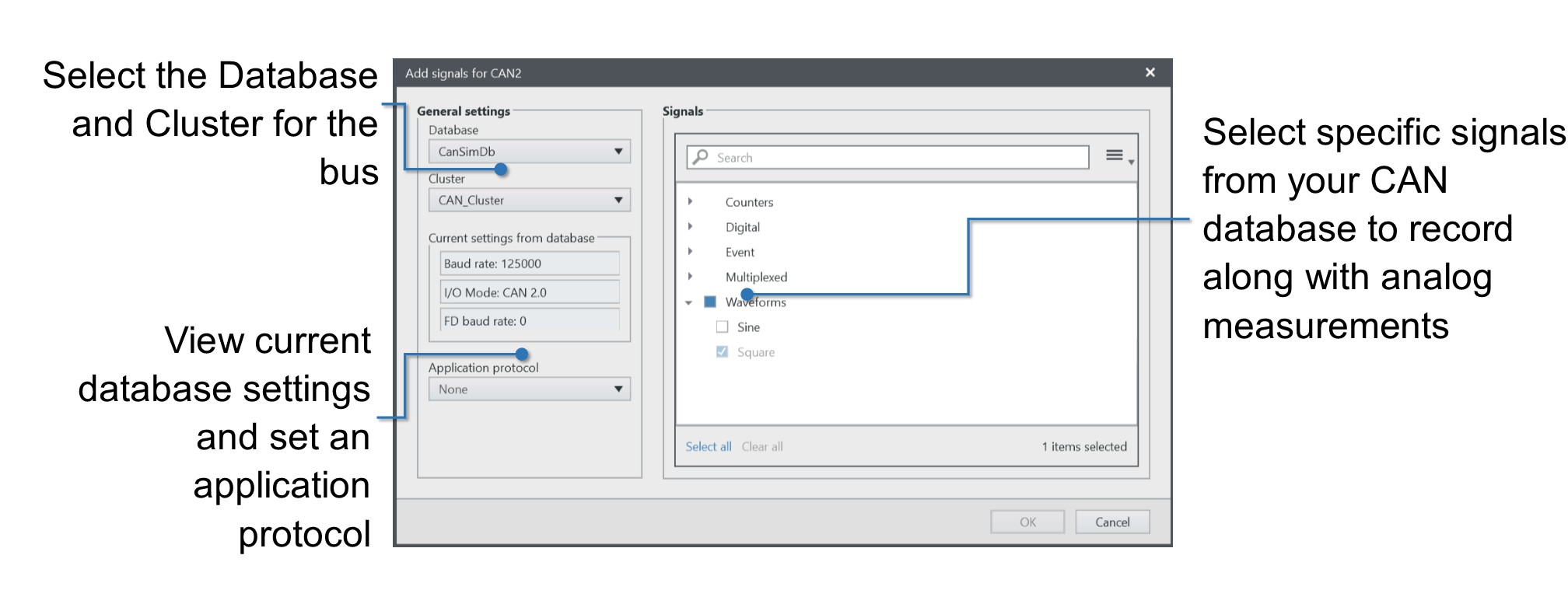

You can also record CAN data along with analog measurements. Upload CAN databases to FlexLogger and configure bus communication settings to acquire CAN messages. After the database is uploaded, select the frames or signals you need to include them in the data file. From FlexLogger, you can also open the Database Editor to create a new database or modify an existing database.

Figure 3: Add CAN Signals

Create Calculated Channels

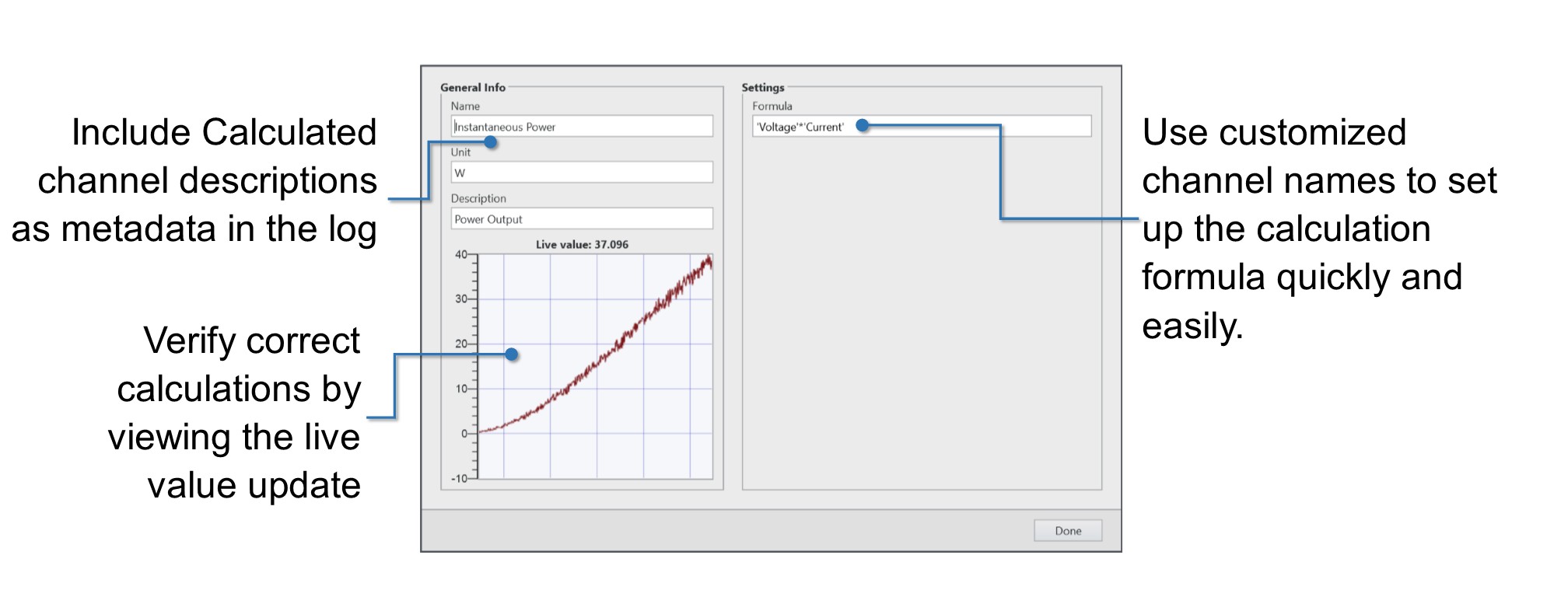

Do you analyze your data after you get a data file from the test? With Flexlogger, create calculated channels to perform arithmetic or trigonometric functions during the test, which are logged to the same file as the raw data. Now you don’t have to wait for a generated file to make key calculations or apply a custom scale. See Configuring Formula-Based Calculated Channels for more information.

Figure 4: Create a Calculated Channel in FlexLogger

Additional Resources

- Now that you've learned about measurement configuration, learn about Running a Test in FlexLogger or Configuring Formula-Based Calculated Channels.

- Do you need a Data Acqusition system but aren't sure what hardware to use? Check out the CompactDAQ Advisor to select the right Data Acquisition Hardware for your project or team.

- Learn more about FlexLogger Software.

- Learn how to expand test coverage and integration with FlexLogger™ Plug-Ins