No Battery? Let’s Test Anyway. The Role of a Battery Emulator in EV Testing

Overview

Aside from being hazardous, electric vehicle (EV) batteries are expensive, and no one wants to render one useless. However, they are the heart of the EV, and just like a real heart, all functions depend on it functioning properly for the vehicle to perform at its best.

To reduce the risks, cost, and time associated with using real batteries, test engineers rely on using a battery emulator to test EV components like the powertrain, fast charger, supply equipment (EVSE), DC/DC converters, and others. By pretending an actual battery is connected to such components, engineers can test in a faster, safer, highly repeatable environment while gaining flexibility and reducing the effect of variables like temperature dependency or human errors in the early stages of test.

Perhaps most importantly, though, engineers gain the scarcest resource there is: Time.

Contents

- Reduce Battery Test Time

- Improve EV Battery Safety

- Increase Repeatability and Accuracy

- Choosing a Battery Emulator

- Next Steps

Reduce Battery Test Time

Using real batteries requires time-consuming processes like charging, discharging, and letting the battery rest to bring it to a test appropriate state of charge (SOC). When using battery emulation, all this preparation is significantly reduced because the battery emulator immediately provides the realistic battery characteristics needed, which helps engineers focus on test instead of battery behavior nuances.

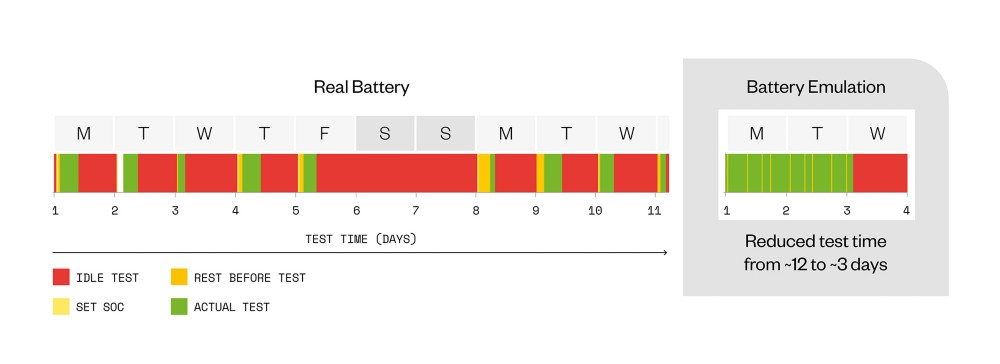

Figure 1: Customer results showed a 70% reduction in total test time by replacing real batteries with an NHR battery emulator.

To demonstrate this point, NH Research (NHR) compiled data from a real-world scenario running nine tests with an actual battery and compared it with the results of the same tests using NHR’s battery emulator. The battery emulator showed a 70% reduction in test time (see Figure 1), coming primarily from the idle and rest times.

Improve EV Battery Safety

Batteries are high-voltage, high-energy devices that pose high risks upon failure, so all related testing is about ensuring not only proper functioning but also safe failing. Risks like exposure to dangerous gases, corrosives, fires, or explosions have led EV companies to create safety policies that state how and when testing with real batteries can be conducted, usually restricting the test time to work hours. Using a battery emulator does not pose these risks, so it provides a way to get ahead of testing without these concerns and limitations.

Increase Repeatability and Accuracy

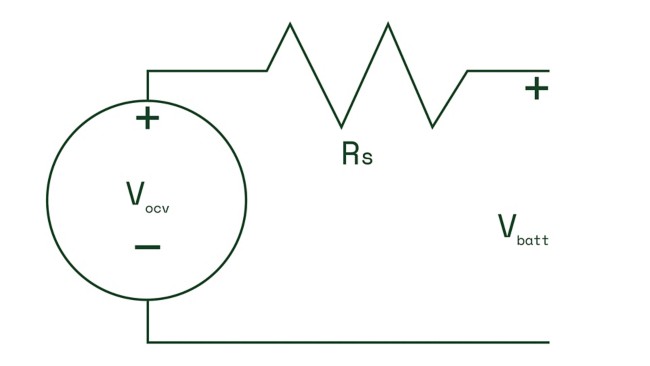

As a battery wears out, its behavior inevitably changes due to charge/discharge cycles or simply because of aging. Additionally, batteries require significant environmental management, such as coolant systems and temperature changes, to operate properly. Because of this, the power output of real batteries lacks the repeatability needed to perform thorough testing of other components. To meet these conditions of being realistic but repeatable, battery emulators model real batteries as a bidirectional voltage source along with a series resistance (see Figure 2). In this way, any battery at any SOC can be simulated, providing repeatable and accurate results.

Figure 2: Equivalent Model of a Battery

Battery emulators must be designed to generate an output that truly represents any SOC of a battery by following that equivalent model. With this “battery emulation mode,” the emulator automatically adjusts the terminal voltage (Vbatt) by measuring the current flowing to and from it and using it to calculate the voltage needed (Vocv) to consistently maintain, like a battery would, the desired output at the terminal, regardless of current flow.

Choosing a Battery Emulator

You need to consider the following when choosing a battery emulator.

Adaptability

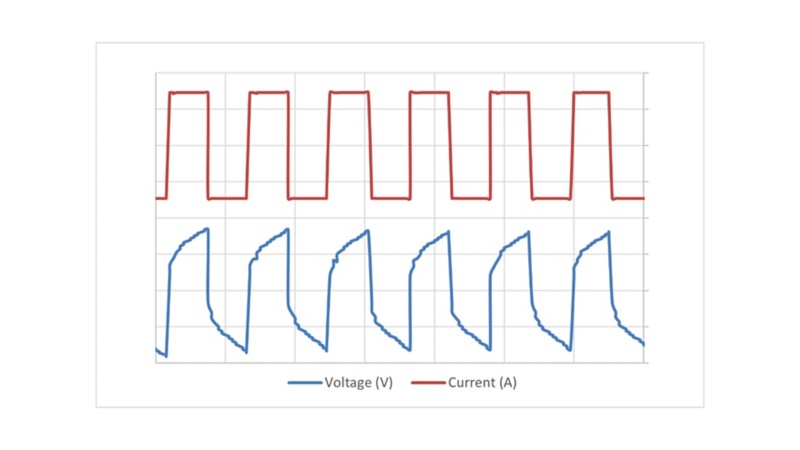

To model any battery and adapt to test needs, the voltage and the resistance values and behaviors of the equivalent battery model need to be programmable. For example, aside from setting the desired voltage, the ability to slew it at slow rates can emulate the change in voltage expected as a battery charges or discharges. Figure 3 shows this effect of programmable series resistance as it is subjected to multiple discharge pulses. Since the change in voltage is proportional to the current with a programmable series resistance model, engineers can test a device as if it were connected to a new (low resistance) or an old (higher resistance) battery. This approach allows for faster, consistent, and safe testing.

Figure 3: EV Battery Simulation Using Series Resistance Model

Low Capacitance

Aside from the programmability of the resistance, a battery emulator must have low output capacitance to accurately emulate the effects of the resistance when the current changes. This is a key differentiation from bidirectional power supplies that usually have high-output capacitance to reduce noise.

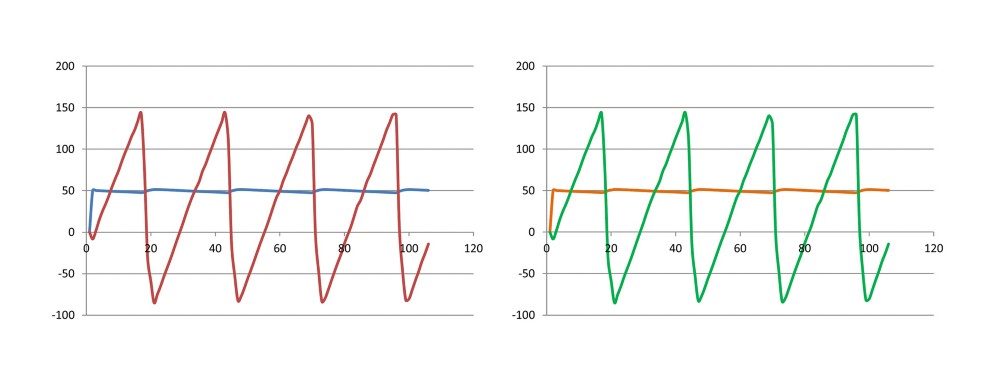

Figure 4 shows a comparison of a real battery and an emulated one. The characteristics of the emulated battery precisely match the characteristics of the real battery, in part because of the low-output capacitance.

Figure 4: Real Battery (left) versus NHR’s Battery Emulator (right)

Scalability through Software

In addition to the low capacitance and programmability of the battery emulator, EV test engineers expect battery emulators to have the following characteristics:

- Bidirectional, isolated terminals that handle back EMF effects safely

- Modularity to add up power and meet test needs as they evolve

- Fast response times to emulate real-world conditions and reduce test time

Holistically testing EV powertrains requires open connectivity and flexible test software to manage multiple test stations, add measurement and communication channels, or integrate with other test equipment. As part of NI’s portfolio, NHR’s battery emulators seamlessly integrate with NI’s test software including VeriStand and TestStand as well as data/asset management tools like SystemLink™ software. EV test engineers benefit from NI’s lossless data logging, automated reporting, integrated workflows, and life-cycle analytics capabilities, which result in lower total cost of tests, shorter time to market, and increased product performance.

Choosing Between Bidirectional Power Supplies and Battery Emulators for Battery Simulation

When deciding between a bidirectional power supply and a battery emulator for battery simulation, there are important considerations. Selecting the wrong equipment can delay projects, increase safety risks and hinder productivity. Using a bidirectional DC power supply for battery simulation can have many limitations in functionality because it is designed as a traditional power supply, not for simulating a battery.

More advanced battery emulators, like NI's Mid- and High-Voltage DC Battery Pack Cycler and Emulator, allow for real- world simulation of battery characteristics by modeling the battery packs series-resistance (RINT). The RINT model provides a simulation of the battery’s internal chemical resistance, along with additional pack resistances created by internal connections, contactors, and safety components. The RINT model can be implemented with a true bi-directional source and a programmable series-resistance.

As in a real battery, NI’s battery emulators adjust the output voltage depending on the direction and amplitude of current flow. This automatic adjustment of output voltage better simulates real-world battery pack characteristics especially when compared with common DC-bus and source/load simulation systems.

NI's battery emulators offer the following benefits over traditional bidirectional power supplies:

- Series resistance—A key feature of battery simulation is having a built-in programmable series resistance with low-capacitance. NI battery emulators have a programmable series resistance that is built into the hardware versus only the software to ensure accurate testing of real-world conditions. As in a real battery, NI battery emulators adjust the output voltage depending on the direction and amplitude of current flow.

- Low output capacitance—Battery emulators with low output capacitance provide accurate simulation of series resistance effects, allowing the output voltage to adjust proportionally to changes in current. By comparison, many regenerative power supplies have high output capacitance to reduce noise output, but this negates the series resistance functionality and can lead to inaccurate battery simulation in addition to slower response rates. NI battery emulators are designed with low output capacitance for fast change of set points to accurately emulate real world conditions.

- Safety—Power supplies generally require add-ons for safety contactors and do not have additional safety features such as interlocks, e-stops, and so on. Adding these components is time intensive and significantly complicates the test set up, adding time delays and additional labor costs. NI battery emulators have all of these features as well as multiple layers of safety built-in.

- Set Accuracy—Power supplies generally only specify load/line regulation (how much an output can change under various line/load conditions) but do not account for the set accuracy or requested output. NI clearly documents empirical control accuracy for all conditions including load/line and error from your requested value.

- Measurement Accuracy—Power supplies are general purpose products, and battery specific measurements such as Ahr or kWhr are often left to the user’s software to track and determine. NI battery emulators take precision battery test measurements directly in the hardware, making programming simpler and more effective.

- Set Methods and Control—Power supplies involve significant software program development before testing can begin. NI battery emulators have operating modes designed to support battery emulation, and our software solutions provide ready to go control solutions to eliminate integration time and effort.