Battery Cell Quality Testing: Making Test a Competitive Advantage

Overview

Batteries are complex. Some aspects of their performance and degradation even experts don’t completely understand. You could argue that testing a battery is closer to testing the human body than a circuit board. Like humans, batteries are dynamic, their condition changes due to their environment and usage, and each one behaves a little differently. Combine this ambiguity with the need to boost performance, reduce testing times, and scale production—and we see that the industry must evolve quickly.

As the automotive industry goes through a massive transformation to electrify vehicles, batteries are front and center. Perhaps no component has ever had such a far-reaching impact on the final product while also undergoing its own rapid pace of technological changes.

Historical approaches to battery cell test do not all transfer seamlessly to new battery technologies, which can yield inaccurate results and inadequate insights. We must re-engineer and transform our processes using AI, ML, automation, and digital transformation to improve accuracy, optimize efficiency, and provide valuable insights.

Batteries present unique test coverage requirements. Automakers are accustomed to testing electromechanical systems, but batteries also comprise chemistry. This additional variable introduces an additional layer of complexity that requires not only electrical and mechanical testing procedures but also necessitates understanding and monitoring the electrochemical processes integral to a battery's operation and performance.

Let’s walk through the basics of battery production, compare testing methods, and discuss advanced testing solutions. Contact us to learn more about NI’s competitive edge in battery cell test.

Contents

- Battery Production Overview

- Benefits of Incorporating Test into Battery Cell Production Test

- NI’s Competitive Edge in Battery Cell Test

- Turn Test into a Strategic Advantage

- Next Steps

Battery Production Overview

It’s difficult to discuss battery cell testing without understanding the production process. Battery cell production requires many steps using different technologies and domains, such as chemical compound mixing, mechanical assembly, material lamination, welding, and more. Each step has a profound impact on the quality of the final battery. To summarize, the production process is grouped into a few macro areas: electrode manufacturing, cell assembly, the conditioning phase, and pack assembly.

Electrode Manufacturing

Electrode manufacturing is where the fundamental components of a battery are made from raw materials. This process starts with mixing a slurry, applying the slurry to metal foils, and cutting the coated foils for further stages. These coated foils become the anodes and cathodes, which are the electrodes of the battery.

A mix of active materials, solvents, and a binder make up the slurry that is used in the electrodes for storing charges. The formula for the slurry depends on the chemistry of the cell and the type of electrode (anode or cathode). The slurry mix sets the stage for the performance of a battery cell. The slurry is applied to metal foils through a precise coating process. The coating must then dry so the solvents can evaporate, leaving only the active material on the foil. The dimensions of the foils influence the cell’s architecture and form factor.

Multiple variables are monitored and controlled during the coating and drying processes. Slurry viscosity, coating speed, and foil tension impact the thickness and uniformity of the coating. Temperature and humidity must be strictly regulated during the drying process. The dried foils are passed and compressed between rollers in the calendaring process. Calendaring improves uniformity, reduces the overall electrode thickness, and smooths out imperfections. The electrode sheets are then precut into manageable shapes for cell assembly.

Cell Assembly

Battery cell assembly is performed in a rigorously controlled environment to avoid degradation of the electrodes from moisture, dust particles, thermal expansion and compression on the materials. The electrodes are assembled in a battery cell through a process of cutting, stacking, packing, and sealing.

- The electrodes are cut into appropriate shapes, depending on the final cell form factor, such as cylindrical, pouch, prismatic, and so on.

- The anode electrodes and cathode electrodes are stacked with a separator between them. Different techniques are used in this process depending on the architecture of the cell. In all cases, the alignment of the layers is crucial to ensure there is no contact between the anode and cathode because any contact would lead to a short circuit.

- Thin strips of conductive metal called tabs are welded to the anode and the cathode. These tabs connect the electrodes to the external circuit.

- The cell is assembled in a preformed packing material, depending on the form factor.

- The packed cells are filled with an electrolyte that facilitates the movement of lithium ions between the anode and cathode during charging and discharging. Absolute precision is required in the filling process. Errors or contamination could degrade the battery’s performance or even pose safety risks.

- The filled cells rest for a period of time, called soaking. The soaking process allows the electrolytes to fully saturate the electrode materials and ensures no air bubbles are trapped in the cell.

- The battery cell is sealed to prevent the electrolyte from leaking and to keep air and moisture from getting in.

Conditioning Phase

At this stage, the battery cell looks like a battery, but it isn’t active. The cell is activated through a process called formation, which enables the cell to store and release electrical energy.

During formation, the battery cell undergoes a charge and discharge cycle. During charging, the electrolyte reacts with the electrode materials, and lithium ions move from the cathode to the anode, forming the SEI (solid electrolyte interphase) layer. The SEI layer prevents the decomposition of the electrolyte while still allowing lithium ions to pass through. After each formation cycle, the battery cell goes through a process of removing unwanted gasses generated by chemical reactions within the cell. The cell is then left to age and stabilize in a controlled environment before undergoing another formation process.

These processes and cycles vary greatly for each cell manufacturer and are repeated with different techniques. This entire phase is crucial for proper operation and longevity of the battery cell. The challenge is that it takes days; and traditionally, you won’t know whether you have a good SEI layer until this process is finished.

Battery Pack Assembly

Battery pack assembly comprises the process of assembling individual battery cells into a complete battery pack. Battery cells must be sorted, modules are assembled and interconnected, and a battery management system (BMS) is installed before being placed in the final enclosure. The BMS is a critical component that monitors and controls the battery pack’s performance. It keeps track of parameters like voltage, current, temperature, and state of charge. It can also adjust as necessary to maintain optimal performance and safety.

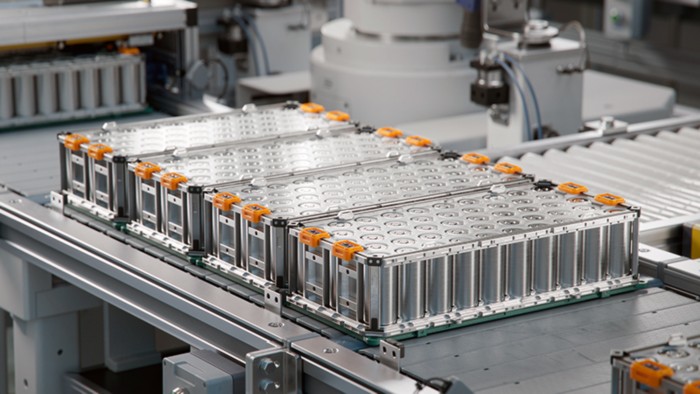

Figure 1: Battery Modules

- The cells are sorted based on their capacities and internal resistances. For optimal performance and lifespan, the cells within a battery pack should have similar performance characteristics. Cells that vary too much could lead to imbalances when charging and discharging, degrading the pack’s performance over time.

- Cells are physically arranged into modules and connected in a combination of series and parallel circuits to achieve the desired voltage and capacity. Multiple modules may be connected by wire bonding or welding conductive strips or wires to the terminals of the cells or modules. The construction depends on the requirements of the device or vehicle where the battery pack will be used.

- The modules and BMS are placed into a casing or enclosure. The enclosure protects the components from physical damage, helps to manage heat, and provides electrical insulation.

Validation engineers use various tests to verify aspects of battery cell quality and performance. Each test has different objectives, advantages, and disadvantages. For more information about these tests, refer to Charging Ahead: Battery Cell Quality Testing in EV Production.

Benefits of Incorporating Test into Battery Cell Production Test

Depending on the application and architecture, a battery pack for an EV can include hundreds or thousands of cells for each pack. McKinsey estimates that global battery producers only have about 10% of the capacity required to meet 2030 targets. The availability and production of better batteries are critical for helping the automotive industry stay on course and meet its projected demands.

Figure 2: Battery Packs

Most people associate quality testing with safety and performance, which are undoubtedly vital, but battery cell quality is also critical for scaling up production, responding to customer demands, and meeting regulatory requirements while keeping an eye on the bottom line.

Detect Defects Early

Each step during battery cell production is critical, and it’s a lengthy process that can take weeks. Top producers must move away from just testing at the end of the line. Test must be embedded throughout the manufacturing process, so defects are found sooner and closer to where they are introduced.

Detecting defects as early as possible allows more efficient raw material use, reduces rework, boosts battery performance, and, ultimately, improves production throughput.

For example, electrode manufacturing is the very beginning of the production process. Multiple defects can be introduced, like cracked coating due to the drying process being too fast, coating not uniformly covering the electrode, wrinkles and cracks in the electrode foils, and so on. Robust inspection processes at this phase are vital to catching defects before investing costly raw materials into a potentially faulty or substandard product.

In later production processes, you might have a bad alignment of the separator and electrodes, dendrites and faulty connections during cell assembly, or an uneven SEI layer during formation. All these defects could lead to performance degradation, accelerated aging, or an internal short circuit that can start thermal events.

Detecting defects early starts by shifting left. Building test into product design not only drives speed and quality, but also pays dividends. Gartner’s research revealed that organizations who paid high attention to product quality early in new product development (NPD) stages earned a 20% higher return than those that did not.

Tools like digital engineering and virtual validation are huge enablers. By subjecting prototypes and experimental designs to rigorous testing, design engineers can assess design flaws, manufacturability, and improvement opportunities. An iterative approach refines the product and technology, ensuring optimal performance and reliability.

Incorporate Hyper-Automation

Performing extensive testing in the battery lab is one thing, but scaling for a high-volume production environment is a new challenge. Rapidly growing production volumes, long testing times, and the physical footprint of the production line present unique complexities for battery cell testing compared to traditional production challenges.

To integrate more testing throughout a battery production environment, automation is an absolute must. It is the cleanest and most reliable way to ensure tight controls, reduce noise in test results, and improve defect detection while driving speed. This consistency is also critical to meet audit and regulatory requirements.

Hyper-automation takes these benefits to the next level with advanced technologies, such as AI, ML, robotic process automation (RPA), and other digital tools. It emphasizes the integration of disparate systems, tools, and data sources for seamless automation across the entire workflow. Hyper-automation must have a place in your test strategy as you look to scale up production, manage costs, and boost quality.

Leverage Data

Thousands of test and measurement nodes are collected across the battery cell production line. Uniform test data enables engineers to learn more about battery systems, quality, and performance. By feeding production data back to validation and product design, the value of the data is maximized to improve the product and hone manufacturing processes.

Technology is evolving quickly, as is the understanding of how defects can be reliably detected using advanced measurements and algorithms. AI and ML can help detect the anomalies that current human understanding still can’t pinpoint. By identifying trends with intelligent analytics, producers can better understand the inner workings of a cell, prevent defects from being introduced, and drive improved battery performance.

NI’s Competitive Edge in Battery Cell Test

EVs, battery manufacturers, and OEMs are under continuous pressure to accelerate production—without sacrificing precision, repeatability, and traceability. As industry players race to achieve their targets, NI has leveraged decades of experience in test, measurement, data acquisition, signal conditioning, and modular hardware to design next generation battery test solutions that solve new challenges.

Figure 3: Battery Cell Validation Lab

These solutions are designed to be future-proof, scale with customers’ needs, and drive value. The wide range of interfaces and software to capture, standardize, manage, and analyze test data in a streamlined way allows NI to cover the wide spectrum of needs across an organization.

NI solutions are at the forefront of battery cell test system technology. These integrated hardware and software solutions are optimized for building automated test systems and advanced analytics with a reduced physical footprint. This approach enables comprehensive testing throughout the production line without time or space constraints. The modular PXI platform powers streamlined workflows and maximum flexibility.

Hardware

The NI EV Battery Cell and Module Production Test System starts with the PXI platform. As a modular system, it orchestrates all instrumentation and functions into a centralized computing system, and PXI modules span a broad array of specialized I/O and instrumentation. With this flexibility, you can achieve a high density of measurement in a single chassis (ACIR, OCV, HPCD, leakage, EIS, and more). The PXI platform also allows a mix of simultaneous and multiplexed inputs, giving producers maximum flexibility to balance cost and production throughput.

PXI is compact and high-performance, allowing users to boost test coverage without sacrificing valuable production space. Users can seamlessly plug in and orchestrate a variety of instruments. The modular design also simplifies calibration and maintenance activities, such as replacing instruments. This platform-based system contrasts with closed solutions that create a vendor dependency. It also eliminates the costs and time constraints driven by customized systems with complex interfaces and integrations. Additionally, since NI’s instruments are software-defined, you can easily change parameters and modify ever-changing requirements, such as test frequencies and currents for ACIR and EIS tests, without replacing the hardware.

- Source measure units (SMUs) provide repeatable and precise measurement and current sourcing for ACIR, EIS, and weld integrity tests. SMUs are optimized for accelerating test execution with automated test systems and parallel test capabilities.

- Digital multimeters (DMMs) are built for automated test and measurement, performing fast and precise voltage measurements for OCV and weld integrity tests. NI’s DMMs acquire high-resolution measurements 36x faster than traditional DMMs, boosting throughput and flexibility.

- NI’s multiplexers are ideal for applications that need to connect measurement or signal generation instruments to various test points on units under test, enabling maximum coverage in a smaller footprint. These high-speed devices use the inherent timing and synchronization capabilities of the PXI platform to communicate with other instruments.

- Additional instruments, such as oscilloscopes and a wide range of input and output interfaces can be added to build mixed-signal test systems with multicore processors and low-latency communication.

Software

NI’s unified software toolchain helps you define, execute, and monitor tests. Advanced analysis capabilities are powered by a unified data pipeline from across the production line. NI software features robust out-of-the-box functionality and easy customizations.

NI offers a comprehensive software portfolio to help boost productivity and tackle your greatest challenges. Here are a few NI software programs designed to streamline and manage your battery cell quality testing processes, data, and assets.

- SystemLink™ software provides the central infrastructure for asset management and test orchestration combined with a centralized data pipeline. Quick data collection, analysis, and reporting boost time-to-insight of test and measurement data to identify opportunities, accelerate decision-making, and maximize throughput.

- TestStand helps test engineers develop, debug, and deploy test systems, providing full visibility into testing processes and results. It automates and accelerates complex tasks such as parallel testing, sweeping, looping, and synchronization.

- LabVIEW is a graphical programming environment for the rapid development of automated test and measurement systems. It features configurable, interactive display elements, custom analysis features, and provides access to the drivers for interfacing with other instruments in the production line. LabVIEW accelerates development time, reduces downtime, and increases code reuse.

- Switch Executive provides interactive configuration and automatic routing capabilities, making it easier to design and manage multiplexer and switch systems. These capabilities decreases the cost for each system while not impacting the throughput of the tester.

NI’s software solutions are intentionally designed to promote openness and innovation. Test engineers have the freedom to make customizations to suit business needs. Whether creating custom dashboards, leveraging open-source databases, or programming propriety protocols and algorithms, NI won’t slow you down your production line with restrictions.

In many cases, the competition will not accommodate software customizations. If they do, you are reliant on them to implement the customization, putting your proprietary protocols, time-to-innovate, and customer deliveries at risk. With NI software, your test engineer can implement customizations without even consulting NI.

Data Analytics

Increasing your test coverage and executing tests faster are only as valuable as your ability to monitor, manage, and analyze the data. NI’s hardware and software solutions are integrated and developed to work harmoniously in a unified language, so your data can drive value beyond its initial purpose of ‘pass’ or ‘fail.’

Smart connected test systems enable producers to improve yields and minimize quality escapes. Insights from one cell can be combined with insights from across the entire production floor. Continuous testing throughout the lifecycle of a battery can reveal if test results suddenly deteriorate, allowing an immediate investigation and driving insights into actions.

Top manufacturers are collecting test data throughout manufacturing processes and using AI and ML to identify trends. This modeling is becoming the secret sauce for each manufacturer to optimize their processes and recipes and, ultimately, produce higher-quality battery cells. NI’s solutions are a great enabler for hyper-automation as producers seek to make test a competitive advantage with these proprietary models.

Turn Test into a Strategic Advantage

The evolution of electric vehicles and renewable energy technologies has amplified the need for more efficient and effective battery cell production, but battery production itself is no easy feat. Increasing battery production while improving cost, quality, and performance is only possible with game-changing solutions.

NI has stepped up to meet these demands with solutions that are aligning to, and defining, the industry's ever-changing requirements. These advanced measurement systems enable manufacturers to understand the inner workings of a cell and drive the improvements necessary to support global demands.

NI is committed to being at the forefront of test system technology and enabling customers meet their goals and engineer ambitiously. Partner with us to turn test into a strategic advantage in this highly competitive and rapidly evolving market.