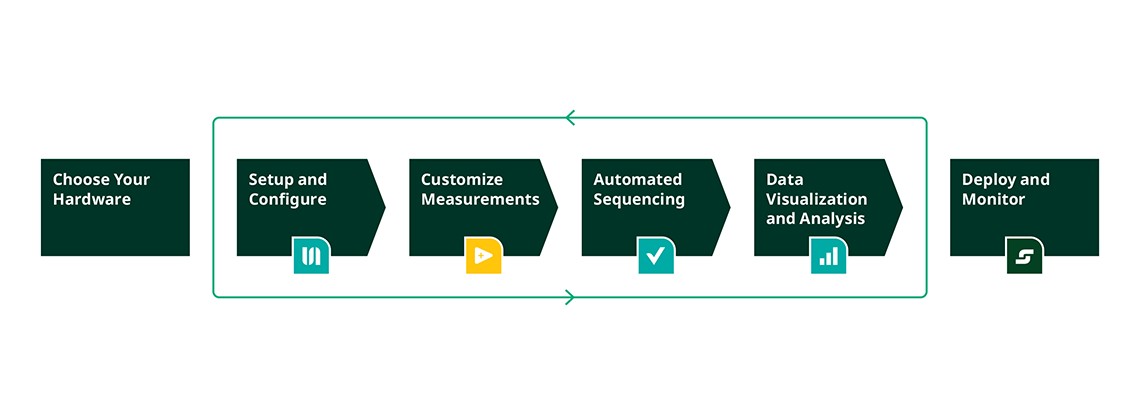

Fundamentals of Building a Test System

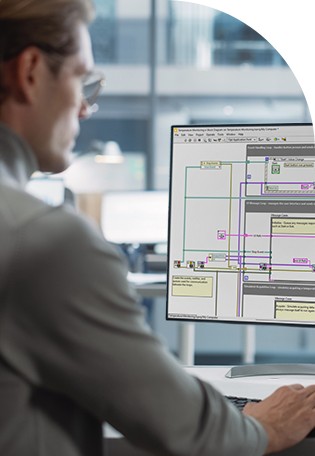

Defining a test strategy and planning test system investments are critical to reducing cost and maximizing efficiency. Learn how to build test systems—including test strategies, best practices, and design trade-offs—from start to finish.