Revolutionizing Rocket Development Efficiency with Testing

Dr. Stefan Tweraser, CEO, Rocket Factory Augsburg (RFA)

Case Study Highlights

- RFA is taking on the challenge of achieving regular and efficient space launches with NI as a test partner across the launch vehicle.

- RFA can test many of the rocket subsystems including structures, avionics, and engines with a small engineering team using NI test tools like LabVIEW, CompactRIO, and CompactDAQ.

- New test capabilities and rocket components or subsystems can be added within days or even hours.

“We see tremendous opportunities in front of us, both for our company and all the customers we serve. NI plays a key role in helping us realize those opportunities.”

—Dr. Stefan Tweraser, CEO, Rocket Factory Augsburg

The Challenge

RFA aims to democratize access to space and reduce launch costs, enabling the launch of satellites into low Earth orbits on a weekly basis with a rocket that flies up to 1.3 tons of payload into orbit very precisely, flexibly, and cheaply—the RFA ONE. Launching into space is still one of humanity’s greatest engineering feats. You only get one shot, and everything must work flawlessly. Accordingly, the development of RFA ONE and its numerous systems is demanding and requires significant model and article testing on an aggressive timeline that keeps RFA ONE ahead of its competitors.

The Solution

The RFA test engineering team started with a core set of test capabilities, including test instrumentation, test code modules, and data analysis based on LabVIEW, CompactRIO, and CompactDAQ products from NI. From there, the team can adjust the test setup or system-under-test quickly, be it adding or changing sensors and test execution sequences or modifying how data is logged—in days or even hours to meet the needs of structural, avionics, engine, or integration test. With these products, a small, skilled LabVIEW development team has been able to support many test and qualification activities.

Getting Off the Ground

Rocket Factory Augsburg (RFA) was founded in 2018 with the vision of enabling a better understanding of Earth with data from space to benefit our planet. Better data enables humanity to target climate change more effectively, optimize logistics routes, manage water and fertilizer, enable global internet and renewable energy control, detect forest fires and other environmental disasters early, and connect self-driving cars with better, more accessible real-time data.

RFA aims to democratize access to space and reduce launch costs, enabling the launch of satellites into low Earth orbits on a weekly basis with a rocket that flies up to 1.3 tons of payload into orbit very precisely, flexibly, and cheaply: the RFA ONE.

The RFA ONE launcher is a medium-sized rocket: 30 meters high, 2 meters wide, and consists of three stages, with tanks made of stainless steel. It is powered by a total of 10 Helix engines and has three key competitive advantages over other launch vehicles:

- Customer-focused service with precise in-orbit delivery and a high degree of mission flexibility through its orbital stage

- A highly competitive price

- Superior staged combustion technology, industrial automation, and low-cost structures

Launching into space is still one of the greatest engineering feats: the harshest environmental conditions, everything must work flawlessly, and you only get one shot at it. Accordingly, the development of RFA ONE and its numerous systems are demanding and require significant model and article testing. RFA follows its own philosophy: away from simulation, towards testing. Per Dr. Stefan Tweraser, RFA CEO, “Simulation is important, of course, but only goes so far. To perfect a complex system like ours, you need test data to make key decisions. NI’s software-enabled solutions are an essential part of our approach.”

Reusing Test Assets across the Launch Vehicle

The RFA test engineering team started with a core set of test capabilities including test instrumentation, test code modules, and data analysis. From there, the team can adjust the test setup or system-under-test quickly, be it adding or changing sensors and test execution sequences or modifying how data is logged—in days or even hours. NI LabVIEW and CompactRIO/CompactDAQ hardware in combination with a small, skilled LabVIEW development team are an ideal platform that can support many test and qualification activities.

RFA engineers can use small, portable test systems built with NI tools as well as complex, permanent test stations. Simple data acquisition systems are typically used to record and analyze a few temperatures, pressures, and flow rates to qualify one of the thousands of parts that make up RFA ONE. Larger test systems could address needs as rigorous as high-precision measurements, real-time control, and simulation. One example is their turbo pump test rig that even includes a powerful helicopter engine. These test systems are deployed across multiple test sites from headquarters in Augsburg, Germany, to Portugal and Sweden. At RFA Portugal, the orbital stage and payload fairing are undergoing vibration analysis and strain measurement test, among many others.

Figure 1: RFA performs structural testing, like a pressure vessel burst test, at their Portugal test site with NI test tools.

Photo by Rocket Factory Augsburg (RFA)

With this in-house agile approach, RFA obtains accurate test results quickly, and they can adapt designs and hardware with agility and flexibility, enabling faster iterations and test loops. This is a huge advantage in one of the most innovative, disruptive, and dynamic industries in the world, and RFA is at the forefront. “We see tremendous opportunities in front of us,” said Dr. Tweraser, “both for our company and all the customers we serve. NI plays a key role in helping us realize those opportunities.”

Figure 2: This RFA turbo pump test rig is built with NI test and simulation software, CompactRIO, and a powerful helicopter engine.

Photo by Rocket Factory Augsburg (RFA).

RFA is not only performing these tests in Augsburg, where its headquarters are located, but also in Portugal and Sweden. The orbital stage and payload fairing are being developed at RFA Portugal. Tests there include vibration analysis and strain measurement of payload fairings. According to Dr. Tweraser, “Our distributed team is part of our strength, enabling us to engage the best experts and resources. The expert assistance we get from NI and its partner network helps to multiply those strengths.”

Figure 3: RFA has instrumented their engine test rig in Sweden with CompactRIO systems that control, monitor, and measure everything from volatile fluid to the engine itself.

Photo by Rocket Factory Augsburg (RFA).

The most complex testing at RFA takes place at the Sweden hot-fire testing site for the unique staged-combustion Helix engine. A distributed, synchronized CompactRIO system controls the plant and the DUT, controls ignition and engine timing sequences, and checks that redline parameters are not exceeded. The system is even entrusted with providing volatile fluids needed in testing like RP1 propellant, liquid oxygen, and nitrogen as well as pyrophoric triethylaluminum and triethylboron (TEA-TEB). The CompactRIO system does all that while also providing synchronized logging and distributed user interfaces for the control room.

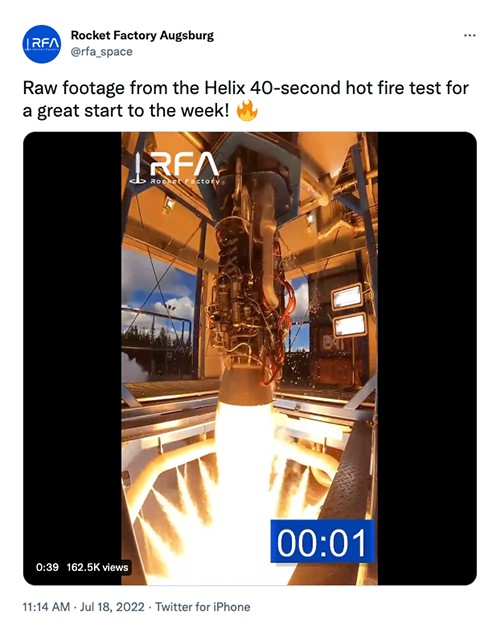

Figure 4: As of July 2022, RFA has performed a 40-second hot fire ignition test of their staged-combustion Helix rocket engine. The test stand used to perform the test is largely composed of CompactRIO distributed systems to control and instrument the rocket engine, fuel systems, and operator interface.

Pohot by Rocket Factory Augsburg (RFA).

Looking Ahead

With this in-house agile approach, enabled by NI test tools, RFA obtains accurate test results quickly, and can adapt designs and hardware with agility and flexibility, enabling faster iterations and test loops. This is a huge advantage in one of the most innovative, disruptive, and dynamic industries in the world. NI is enabling the rapid development of new launch vehicle technologies, like those at RFA, across the space industry with a flexible, easy-to-use rocket engine test platform. This agility is helping to keep RFA at the forefront.