NI LabVIEW Empowers Scientific Research at CERN's Antimatter Lab

Marco Volponi, Senior Research Fellow, CERN

Case Study Highlights

- LabVIEW enabled the creation of an advanced automation system, significantly enhancing efficiency and reliability in complex antimatter research at CERN.

- The solution cut data-taking time by 18 percent, increased antimatter trapping efficiency by more than 100%, and enhanced safety, enabling unsupervised, 24/7 automated operations.

- LabVIEW’s versatility and scalability allowed for successful deployment across multiple experiments, showcasing its potential for broader scientific applications.

“The NI LabVIEW automation system has been transformative for our AEgIS experiment at CERN. We’ve cut data-taking time by 18 percent, boosted antimatter trapping efficiency by more than 100 percent, improved safety, and can now run experiments unsupervised. Its success across multiple projects proves its potential for streamlining scientific research automation.”

—Marco Volponi, Senior Research Fellow at CERN

The Challenge:

Precision is vital in scientific research, especially in CERN’s AEgIS experiment studying antimatter. This complex project demands precise coordination of devices to the nanosecond. Previously, manual adjustments made by researchers were labor intensive and error prone, limiting their ability to focus on data analysis and further experiments.

The Solution:

The AEgIS Collaboration addressed challenges by implementing Computer Interface for Reliably Controlling, in an Unsupervised Manner, Scientific Experiments (CIRCUS) with Total Automation of LabVIEW Operations for Science (TALOS). This system, built with NI LabVIEW, automates experimental sequences, reducing human intervention. LabVIEW’s Actor Framework provides a robust, distributed control architecture, enhancing reliability, stability, and efficiency.

The Quest for Understanding Antimatter

Antimatter is the mirror image of ordinary matter, as it consists of particles of the same mass but with opposite charges and properties. Understanding antimatter is crucial because it could unlock answers to the key cosmological question as to why our universe is made predominantly of matter and not an equal mix of matter and antimatter.

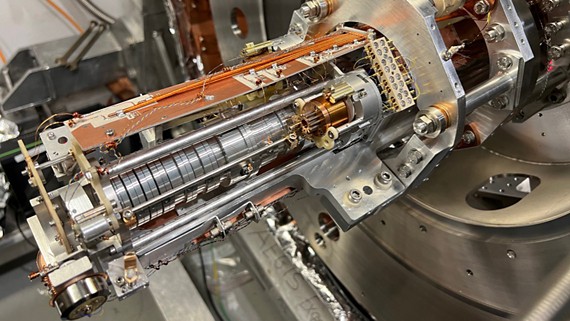

Figure 1: AEgIS anti-hydrogen production trap, exposed by the opening of the main cryostat.

The AEgIS experiment aims to test fundamental principles of physics using antimatter, including the behavior of anti-hydrogen under gravity. This research could potentially reshape our understanding of the universe. However, working with antimatter is no simple task: it requires incredibly precise measurements and accurate control over extreme experimental conditions (such as electromagnetic particles confinement, in a better-than-space vacuum at almost absolute zero temperature). To achieve this, perfect coordination of hundreds of devices is required, synchronizing their operation with nanosecond precision. One can think of it as trying to conduct a symphony orchestra where each musician (in this case, each piece of equipment) needs to play their part with perfect timing and precision, 24 hours a day, 7 days a week. The need for advanced automation becomes crucial.

The Birth of CIRCUS and TALOS

Recognizing the limitations of manual control, the team at CERN developed CIRCUS, with TALOS and LabVIEW as its core. This system transformed their operational landscape, much like how modern autopilot systems have revolutionized aviation. The integration of LabVIEW facilitated the creation of a distributed system architecture, which united individual machines into a coherent, automated network.

TALOS acts as the conductor of this complex orchestra. It coordinates all aspects of the experiment, from controlling individual pieces of equipment to managing and overseeing the entire experimental flow. Each component within the system operates as a microservice, offering modularity and flexibility. This architecture means that different parts of the experiment can be updated or modified separately—and, in case of a problem, immediately reverted without causing the entire system to malfunction. This feature is crucial in a research environment where adaptability is key, and system uptime and stability of foremost importance.

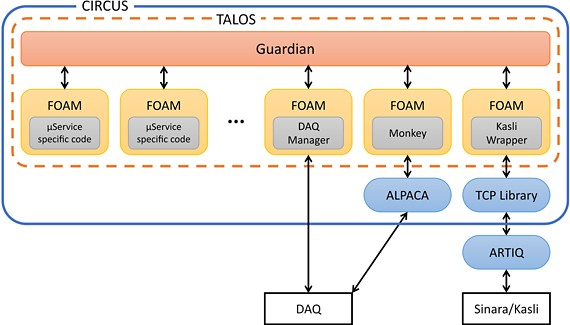

Figure 2: Scheme of CIRCUS and TALOS, depicting the relation between Guardian, MicroServices, Sinara (AEgIS’ FPGA), ALPACA (analysis framework), and the data acquisition system (DAQ). The actor-based structure of TALOS is the base of the interface between the guardian (the root actor) and the MicroServices, encapsulated into the father of all microservices (FOAM). In each MicroService, only the code for the specific functionalities needs to be implemented. Three notable MicroServices are explicitly mentioned: the DAQ Manager, controlling the interaction with the DAQ; the Monkey, the core of the automation and managing the interface with ALPACA; and the Kasli Wrapper, carrying the interaction with the FPGA.1

Achieving Unprecedented Operational Efficiency

The implementation of CIRCUS and the LabVIEW-based framework, TALOS, resulted in remarkable improvements in efficiency and reliability. As an example, during the course of a 69-day data-taking campaign, TALOS’s automation saved 18 percent of data-taking time. Although this time saving might not sound like much, in the world of atomic physics, where experiments can run for months or even years, this time represents an enormous surge in productivity.

One of the most remarkable features of the system is its error management capabilities. TALOS includes a scheduler for writing experimental test scripts, a Monkey to execute them and make high-level decisions, and an error manager with user-defined error conditions and precise countermeasures for managing distributed system errors. These elements together guarantee that any issues are promptly addressed, hence maintaining the integrity and efficiency of the experimental processes. This architecture is like having a team of vigilant assistants who are constantly keeping an eye on every aspect of the experiment and are ready to step in at a moment’s notice.

Figure 3: A screenshot of the CIRCUS control system executing a schedule of experiments involving antimatter. The primary interface is provided by TALOS. Located in the upper left corner are the Guardians and MicroServices watchdogs, while the error list is positioned in the upper right corner. In the right-hand column, the top section provides specific details regarding the selected error and, underneath it, a real-time log displays Kasli operational activities. This interface is uniform across all experiment machines. Within the main window, the Captorius 3 Manager MicroService is displayed, controlling the acquisition of the experiment’s main oscilloscope.

The system’s ability to operate autonomously, particularly during nights and weekends, has been a game-changer, making it possible to gather data more continuously and freeing up researchers to focus on theoretical and data analysis work. This shift from a laborious manual operation to an automated control represents a significant leap forward in how complex scientific experiments are carried out.

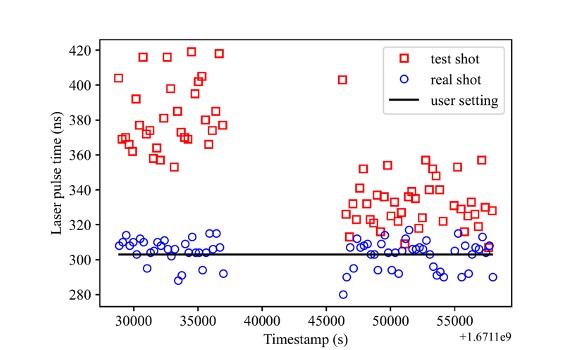

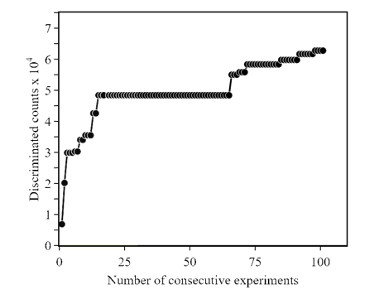

Moreover, the precision and synchronization capabilities of TALOS, joined to the feedback on data acquired (which can be empowered by AI solutions), have opened the realm of experimental possibilities, dramatically improving the machine performances and enabling new measurements altogether. An example is the automatic antiproton beam steering procedure, an operation that once took weeks to be performed manually. Now, it can be carried out periodically in full automation in a matter of hours, resulting in an increased trapping efficiency of more than 100 percent. The best example of the enabling capabilities is the automatic per-shot adjustment of the time drift of the positronium laser: by bringing down the uncertainty from ~100 ns to some ns, TALOS rendered possible the world-first laser cooling of positronium atoms, an achievement sought in the field for more than 30 years.2

Figure 4: A feedback loop uses the uncorrected laser pulse timings (red squares) to calculate the deviation from the user setting (solid black line) over the course of an hour and corrects the timing of the subsequent desired laser pulse that is used for the actual experiment (blue circles). Independent of short-term to long-term drifts or even sudden jumps, the resulting timing is always close to the desired value.3

Figure 5: Convergence plot of the autonomous beam steering optimizer. On the Y axis, the annihilation counts (proportional to the caught antiprotons) are displayed, while on the X axis the iterations of beam steering configuration are shown. A clear increase of the number of trapped antiprotons is visible.

Conclusion

The application of NI LabVIEW in the development of the CIRCUS and TALOS systems at CERN’s AEgIS experiment exemplifies a successful case of advanced automation in complex scientific research. This technology not only enhances operational efficiency and data quality (by increasing procedures standardization and repeatability and performing low-level data quality checks), but also establishes a standard for future autonomous control systems in various scientific and industrial applications. The automation, error handling, and modular architecture provided by LabVIEW have proven to be crucial in attaining the ambitious goals of the AEgIS experiment, showcasing NI’s pivotal role in advancing scientific research.

The implementation of this LabVIEW-based system has offered various benefits to the research team. The automation capabilities have resulted in significant time savings, allowing researchers to dedicate their time focusing on data analysis and other key activities rather than manual system management. The enhanced safety and stability features have improved the overall security of operations, mitigating the risk of potential damage to expensive equipment. Precise orchestration and repeatability of measurement procedures have both boosted the results achieved and enabled new experiments altogether. Furthermore, the scalability and agility of the LabVIEW-based solution have enabled efficient system migration and expansion, with multiple team members able to contribute seamlessly.

This success story not only showcases the power of LabVIEW in scientific research but also highlights its potential applications across a variety of industries where precision, automation, and reliability are paramount. From manufacturing to aerospace, the principles and technologies established by CERN’s antimatter research could pave the way for more efficient, reliable, and innovative automated systems in diverse fields.

References

1 Volponi, M., Zieliński J., Rauschendorfer T., Huck S., Caravita R., et al (the AEgIS Collaboration). TALOS (Total Automation of LabVIEW Operations for Science): A framework for autonomous control systems for complex experiments. Rev. Sci. Instrum. 95 (2024); doi: https://doi.org/10.1063/5.0196806.

2 Glöggler, L. T., Gusakova, N., Rienäcker, B., Camper, A., Caravita, R., Huck, S., Volponi, M., et al (the AEgiS Collaboration). Positronium Laser Cooling via the 13S-23P Transition with a Broadband Laser Pulse. Physical Review Letters 132, no. 8 (22 February 2024): 083402. https://doi.org/10.1103/PhysRevLett.132.083402.

3 Volponi, M., Huck S., Caravita R., Zieliński J., Kornakov G., et al (the AEgIS Collaboration). CIRCUS: An Autonomous Control System for Antimatter, Atomic and Quantum Physics Experiments. EPJ Quantum Technology 11, no. 1 (15 February 2024): 10. https://doi.org/10.1140/epjqt/s40507-024-00220-6.