Chapter 3: Connectivity Options for RF Switch Applications

Overview

This document is part 3 of the Guide to Selecting an RF Switch. This 5-part guide is an accumulation of insightful content that will arm you with the necessary knowledge to design your RF switch network. This section will provide you with an overview of the smaller but equally important components that form a part of the switch network, such as cables, and connectors. Please see the related link section below to navigate to the first page of the guide.

For more information on NI's RF switch offering visit NI RF Switches main product page.

Contents

- Introduction

- Cables

- Cable types

- Cable Terminations (Connectors)

- Connector Types

- Conclusion

- Related Links

Introduction

When designing an RF switch system, it is easy to focus on the performance of the switch module while neglecting smaller system components such as cables and connectors. However, it is important to understand that each piece of an RF system contributes to signal degradation in the form of reflections and losses. For this reason, in order to obtain optimal system performance you must place as much attention on choosing the right cable and connectors for your system as you would on choosing the right switch module. If care is not taken when doing so, overall system performance can be severely affected. To learn how to choose the right cables and connectors for your system, it is important to understand the advantages and disadvantages of the various options available.

Cables

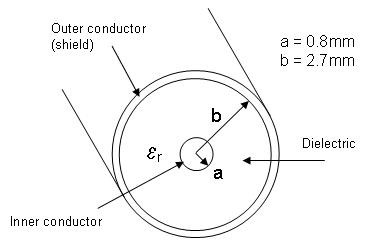

Most RF systems use coaxial cables for signal transmission. The three main parts of a coaxial cable are its center conductor, outer shell, and dielectric which acts as an electrical insulator by preventing the current dissipation between the center conductor and outer shell (see figure 1). Because coaxial cables contain the propagating electromagnetic signal on their insides (the inner conductor in the figure below), they do not radiate noise and are less susceptible to picking up other signals that may persist in the vicinity.

Figure 1. Example of a coaxial cable

There are several properties of coaxial cables that can affect system performance. These include cable attenuation, cutoff frequency, and characteristic impedance.

Cable Attenuation

The total attenuation that a cable will impose on a signal that it is being used to route depends on its conductive and dielectric loss. Conductive loss which is also referred to as ‘resistive loss’ or ‘ohmic loss’ in turn depends on:

a. The metal used to build the coaxial cable (usually copper or silver due to their high conductivity)

b. Diameter of the cable’s center and outer conductors

One way of reducing conductive loss in an RF system is to use a cable with a larger diameter. Larger cables contain more metal for conducting current and therefore offer less attenuation per unit length than smaller ones.

It is also important to note that the amount of conductive loss introduced by the cable depends on the frequency of the signal it is being used to route. As frequency increases, current density tends to concentrate near the outer surface of the inner conductor and the inner surface of the outer conductor (a phenomenon known as ‘skin effect’). This causes conductive losses in any cable to increase in a manner that is directly proportional to the square root of frequency of the signal of interest.

In addition to conductive losses, power is also dissipated in the dielectric (the material between center and outer conductors) of the cable. This type of power loss is referred to as ‘dielectric loss’. For coaxial cables, dielectric loss is linearly dependant on frequency and proportional to the square root of the dielectric constant (or permittivity) of the material used between the center and outer conductors of the cable. At frequencies above several GHz, dielectric losses can become more significant than conductive losses.

The combination of conductive loss and dielectric loss in a cable is commonly referred to as its ‘attenuation factor’ which is usually expressed in terms of dB per length of cable. Values for attenuation factor are typically listed in the cable manufacturer’s data sheet. Cables with larger diameters typically exhibit lower loss and are capable of transmitting higher power levels than smaller ones.

Cutoff Frequency

Cutoff frequency is the maximum frequency up to which a cable can be used. Above its cut off frequency, a cable will significantly deteriorate the quality of a signal that passes through it. A cable’s cutoff frequency is inversely proportional its diameter. Hence, smaller cables can operate at higher frequencies than larger ones. For all practical purposes however, even larger diameter cables which have diameters of ½” have cutoff frequencies well above 10 GHz. Hence, for most switching systems, cutoff frequency is less of a concern than cable attenuation.

Characteristic Impedance

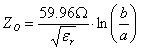

In order to ensure maximum power transfer from source to load in RF systems, the characteristic impedance of the cable should match that of the source and load. Most RF switching equipment is designed to have a characteristic impedance of either 50 or 75 Ω (for communications and video applications, respectively). Similarly, cables are specifically designed for these two impedances as well. Characteristic impedance of a cable is based on it’s per- unit- length resistance, conductance, capacitance and inductance, which in turn are dependent on the cable’s physical dimensions as well as the dielectric used to separate the two conductors. Common materials used for the dielectric are PTFE (Teflon®, a registered trademark of DuPont) and polyethylene. The formula to calculate the characteristic impedance of the cable shown in Figure 1 is:

If we assume that which is the relative permittivity of the dielectric (dielectric constant) is 2.1 we calculate characteristic impedance of this cable to be 50.3 Ω.

As can be seen, the characteristic impedance of the above cable can be easily changed by changing its symmetry (i.e. changing lengths of inner and outer conductors) or by changing the material of the dielectric.

The dielectric constant of the material used will also determine the velocity factor, or the speed at which a wave propagates down a cable. The velocity factor is usually expressed as a percentage of the speed of light.

Propagation Velocity (m/s) = Velocity Factor x (3 x 108)

Construction Quality

Construction and quality of materials used will naturally affect performance of a cable. Better quality material will naturally improve performance of the transmission line or cable, but it will also be more expensive.

All coaxial cables are manufactured with either a solid or stranded center conductor. Both variations have their strengths and weaknesses. A stranded center conductor allows for a more flexible cable that will last longer due to lower stresses on the cable and connectors. On the other hand, cables with solid center conductors are typically cheaper to manufacture and exhibit lower attenuation per unit length than stranded cables.

In addition to the construction of the center conductor, insulation on the outer conductor or the lack there of can also affect losses in the cable. For example, semi-rigid cable types, which have a solid insulating outer shield, often have the best isolation specifications of all cable types. As a result of this high isolation, semi-rigid cables are ideal for RF systems that function in noisy environments.

The materials used to construct a cable also determine its minimum and maximum operating temperatures. Some cable types are designed to operate outdoors or be buried, while others are not. Care should be taken when designing a test system to ensure that the cables used in the system are capable of withstanding the environmental conditions they will be subjected to.

Cable types

There is no single cable that is best for all applications. Many factors, including performance requirements, flexibility requirements, price, and required length, will determine which cable is best for a given test system. An overview of several different cable types follows.

Semi-rigid

Figure 2. Semi-rigid SMA-SMA cable

Semi-rigid (non-conformable) cables are designed for high performance applications (in excess of 100 GHz for some cables) where installation is permanent and movement of cables post installation is minimal. The outer shield in the case of this cable is a solid piece of metal, usually copper, which must be formed into place using specialized tools. Semi-rigid cables cannot typically be reformed without damaging the outer shield and are therefore not as flexible as conformable ones. However, because the outer shield is solid, isolation performance is the highest of any cable type. Semi-rigid cables do not typically have an outer jacket.

Third party vendors are capable of bending the semi-rigid cables into any three-dimensional shape based on a customer drawing. Semi-rigid cables are designed for both 50 and 75 Ω RF systems.

Conformable

Figure 3: Conformable SMA-SMA cable

Conformable cables are similar to semi-rigid ones but have an outer shield that is made of a braided material (usually a Copper-Tin composite) rather than a solid piece of metal. Most conformable cable types are rated for at least 15 GHz. The braided construction creates a more flexible cable which does not require special tools to bend into place. Once the cable is formed, it will retain its shape indefinitely. Conformable cables can bent in to different shapes several times without damage.

Even though they are more flexible than semi-rigid cables, conformable cables work best in applications where they will not be moved often. While more flexible than semi-rigid, performance of conformable cable will deteriorate quickly, usually at the cable ends near the connector, if the cable is constantly moved, bent, or twisted. Conformable cables do not typically have an outer jacket.

Raw conformable cables (cables that do not have connectors on their ends) as well as conformable cable assemblies with standard connectors cut to standard lengths are available from numerous vendors. Conformable cables are made for 50 and 75 Ω RF systems.

Flexible Cables

Figure 4. Flexible coaxial cable, SMA-MCX

Flexible cabling performs well in applications where movement of test cables is common, or frequent connections to a Device under Test (DUT) are required. 75 Ω Flexible cables bend easily for quick connections, but do not necessarily retain their shape. Numerous variations of flexible cables are available, with specialty types designed for low loss, high power, or extra flexibility. The isolation performance of flexible cables (usually listed in the cable’s data sheet) varies greatly and depends on the coverage of the outer shield conductor. Flexible cables usually have an outer jacket made of PVC or a similar material.

Raw cables as well as common configurations of flexible cable assemblies are available off-the-shelf from numerous vendors. Cable assemblies with custom lengths and connector configurations can be built by hand or purchased from vendors who specialize in such designs. Adding shrink wrap tubing to the ends of cable assemblies may help extend their lifetime by reducing their bend radius. Flexible cables are available in numerous characteristic impedances, including 50 and 75 Ω.

Cable Terminations (Connectors)

Cable terminations connect the raw coaxial cable to a Device under Test (DUT) or test system. Terminations can vary greatly in both quality and cost. Like in the case of cabling, the specific application or use case will often determine which connector type is most suitable. There are two main methods for attaching connectors to cable. Given the right tools, both can be assembled by hand. Most manufacturers provide assembly instructions for the connectors they sell.

Solder-Type Connectors

Solder type connectors connect the outer shield of the cable to the outer metal piece of the connector via a solder connection. This type of connector is designed to be used with semi-rigid or conformable cables. When using a solder type connector, it is important to ensure that there is a good solder fillet around the entire connector body. Solder connections are typically stronger than crimp connections.

Crimp-Type Connectors

Crimp type connectors hold the shield and connector body together using a compression connection between the two. This connector type is best suited for use with flexible cables. The connector typically has two pieces, the connector body and a crimp sleeve. During assembly, the shield of the cable is placed between the two parts, and the crimp sleeve is then deformed around the connector body. For best performance when using this type of connection, the crimp joint should be uniform and made with the crimping tool suggested by the manufacturer.

Figure 5. Crimp (left) and solder (right) type SMA connectors

Connector Types

Numerous connector standards have evolved over the years and each one has advantages and disadvantages. Like coaxial cables, connector types have a cutoff frequency above which, they are no longer useful. Some of the more common connector types used in RF systems have been discussed below. All of the following connectors are impedance matched to a specific characteristic impedance. Quality of such connectors varies and dependson manufacturer.

Type N

Figure 6. Female type N connector on a Network Analyzer

N connectors are the oldest of all connector types discussed in this section. However, the ruggedness and high power capacity are features that have kept this connector popular for some applications. It is one of the larger RF connectors available with a maximum frequency of 11 GHz.

The N connector employs a threaded interface which can be hand tightened. A 75 Ω version of the connector is also available, but the two versions of the connector are not compatible and 75 Ω N connectors can be damaged if they are connected to 50 Ω equipment. Most N connectors are designed to work only with flexible coaxial cable types, although some special cables with solid outer conductors designed with flexibility in mind can be used as well.

SMA

Figure 7. Single-slot PXI module with female SMA connectors

SMA connectors are very common in RF equipment and are available from numerous manufacturers. The connector itself is substantially smaller than the N connector and hence has a higher frequency limit of 18 GHz, typically. Some manufacturers make SMA v2.9 connectors for frequencies as high as 40 GHz. Like the N connector, the SMA is a threaded interface, but it must be tightened using a torque wrench in order to obtain optimum performance. SMA connectors are only manufactured for use in 50 Ω RF systems.

SMA connectors are widely available for semi-rigid, conformable, and flexible cable types.

SMB

Figure 8. Single-slot PXI module with male SMB connectors

Unlike N and SMA connectors, SMB connector use a press-on interface (the connectors are mated by pressing them together, usually with some sort of retention mechanism), allowing for quicker connect and disconnect times. When fully engaged, the connectors will snap together. The size of the SMB connector is slightly smaller than that of the SMA. Unfortunately, the SMB connector is neither rugged nor precise, and its frequency range is therefore limited to 4 GHz.

SMB connectors are available for semi-rigid, conformable, and flexible cabling types. Standard SMB connectors are only designed for 50 Ω RF applications. Although a 75 Ω SMB interface does exist, it is not the same size as 50 Ω SMB connectors. SMB connectivity is not as widely used as SMA.

BNC

Figure 9. Single-slot PXI module with female BNC connector

The BNC connector is one of the oldest types of RF connectors and is still widely used in applications with frequencies of 4 GHz and below. Like the SMB connector, the BNC connector is relatively quick to connect and disconnect, and utilizes bayonet lugs for cable retention. The cable is twisted on approximately ¼ turn until the bayonet lugs secure the two halves together. BNC connectors are available for almost every type of cable and assembly method.

Mini-75 Ohm SMB

Figure 10. Single-slot PXI module with male mini-75 Ohm SMB connectors

The mini-75 Ω SMB is a 75 Ω version of the standard 50 Ω SMB connector. The major advantage of the mini-75 Ω SMB over other 75 Ω connectors is its size. Mini-75 Ohm SMB connectors are rated from 2-3 GHz depending on manufacturer.

MCX

Figure 11. Single-slot PXI module with female MCX connectors

The MCX connector was created to bring higher performance to an RF connector in a smaller package size. MCX is a press on connector interface like SMB, but is 30% smaller. MCX connectors are rated up to 6 GHz and are available in 50 and 75 Ω configurations. Like the SMB connector, the MCX is not as rugged as connectors with a threaded interface. Also, MCX cables may not be as common as SMA or SMB and it is therefore harder to interface with MCX connectors than it is with SMB and SMA connectors.

Conclusion

You should consider the strengths and weaknesses of each connector and cable type when designing your RF system. Although you will have limited control over certain aspects of your system, such as connector type of the actual instrument (RF analyzers and generators) or actual Device under Test (DUT) you can improve system performance by making appropriate cable choices that work best with the connectors in your application. .

When designing your system you must also carefully when picking your switch modules. For example, it is often unadvisable to choose a 75 Ω switch module with SMA connectors, because SMA connectors always have a characteristic impedance of 50 Ω. Last but not least you must pick system components that offer better performance than the DUT. For example, when testing a 4 GHz DUT, a test system constructed of switches and cabling with SMA connectors and low-loss cabling would contribute less error to a system than one with SMB connectivity and standard cabling. Cables and connectors might not be the most expensive parts of your RF system but they can certainly cause a drop in performance if care is not taken when choosing them.