Advantages of NI Switches

Overview

Many automated test applications require routing signals to a variety of instruments and devices under test (DUTs). Often the best way to address these applications is to implement a network of switches that facilitate this signal routing between the instrumentation and the DUTs. Switching not only handles this signal routing, but it is also a low-cost way to increase the channel count of expensive instrumentation while increasing the flexibility and repeatability of your measurements.

When adding switching to an automated test system, you have three main options: (1) design and build a custom switching network in-house, (2) use a stand-alone box controlled via GPIB or Ethernet, or (3) use a modular platform with one or more instruments such as a digital multimeter (DMM). Switching is almost exclusively used alongside other instruments, so tight integration with those instruments is often a necessity. An off-the-shelf, modular approach can meet these integration challenges inherent in most common test systems.

NI offers hundreds of switching topologies for the modular PXI platform. You can combine these modules with NI PXI instruments such as RF analyzers/generators, digital multimeters, and oscilloscopes to build flexible, high-channel-count automated test systems.

Contents

Hardware Overview

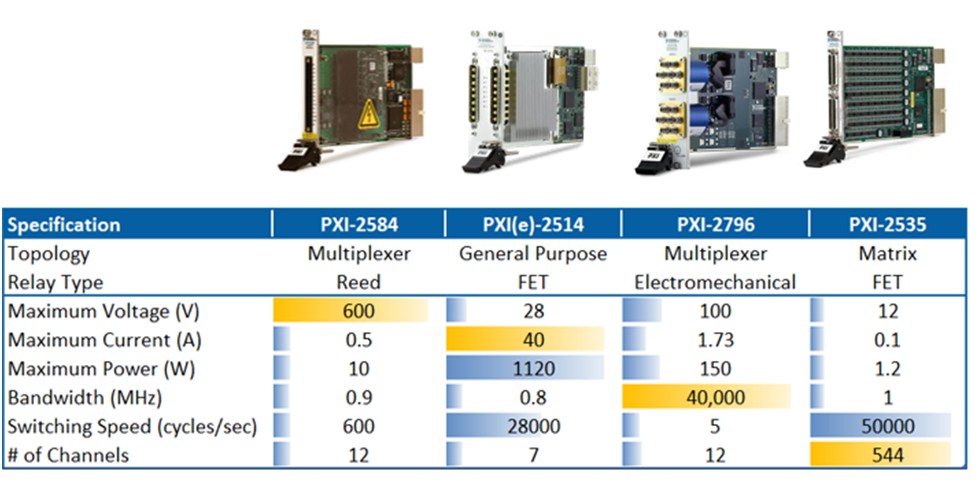

NI provides high-density switching for a variety of I/O points from DC to RF. Applications for these switches range from general-purpose functional test to more application-specific modules for semiconductor parametric test, high-power fault insertion, and radar test up to 40 GHz. These switches use a variety of relay types such as electromechanical armature, reed, solid-state, and field-effect transistors (FETs).

Figure 1: NI offers a wide range of PXI switches for switching high-voltage, high-current, and high-frequency signals.

NI switches offer the following advantages that can simplify your test development process and reduce the overall cost of test.

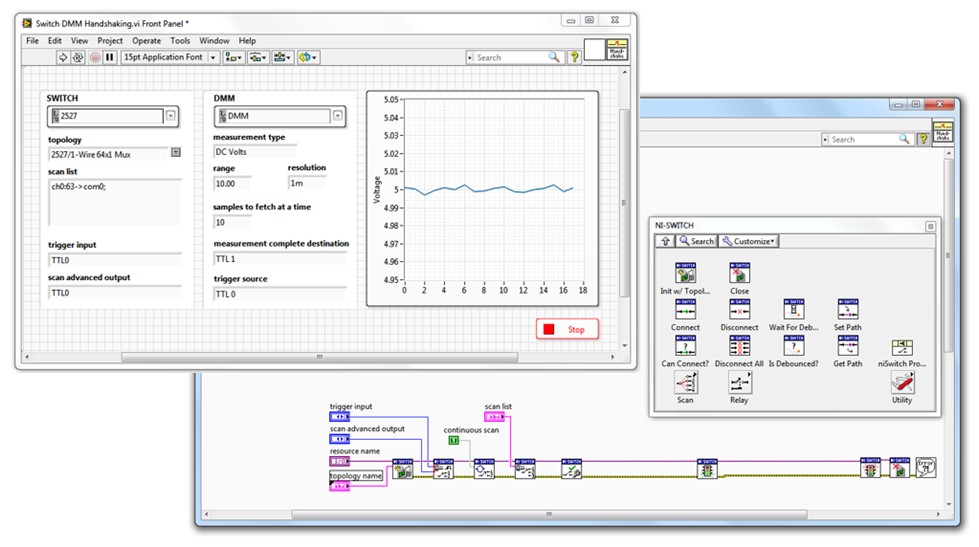

Hardware Scanning

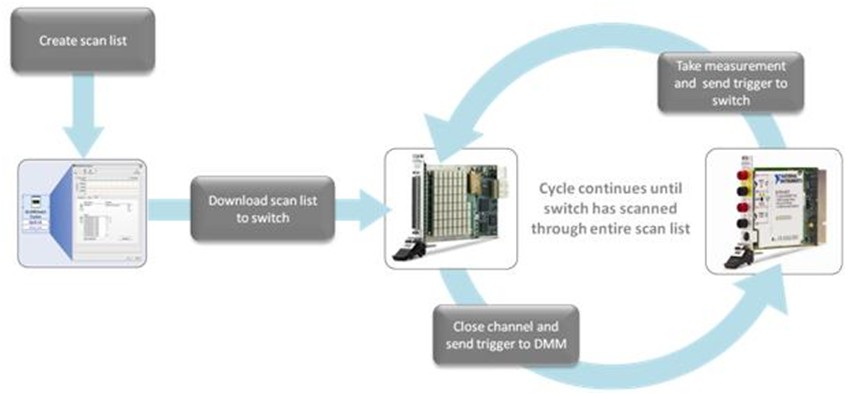

Maximizing throughput is a common requirement in automated test applications. To increase system throughput, many NI switch modules support hardware scanning, which allows you to download a list of switch connections to the onboard memory of the switch, and use the PXI backplane to communicate with other instruments such as a DMM. This removes the software overhead associated with traditional software-based scan lists and increases the determinism and speed of the scan list execution.

With hardware-timed handshaking, the measurement device, such as a DMM or RF analyzer, issues a digital pulse after each measurement and thus triggers the switch to close its next connection in the scan list. This process ensures optimal throughput because the entire measurement sequence is hardware-timed and has no additional software delays. Figure 2 illustrates this process.

Figure 2: Switch and DMM handshaking allows you to create hardware-timed scan lists.

Because of this determinism, additional software activity (such as adding extra data processing) does not affect the results of the hardware handshaking test as it does when software scanning is used.

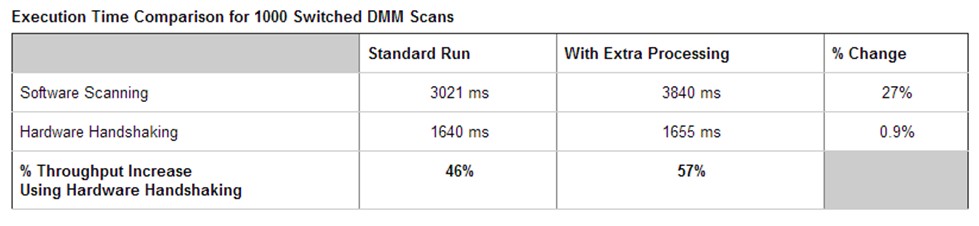

Table 1 shows the execution time improvement of hardware handshaking. These are benchmark results for 1,000 switched DMM scans using an FET-based multiplexer and an NI PXI DMM. The use of hardware handshaking increased execution time more than 46 percent. Also note that the hardware-handshaking use case is more resilient to extra software processing tasks, which severely slows execution of software scanning.

Table 1: Scanning facilitates hardware-timed measurements and increases throughput.

Predictive Maintenance

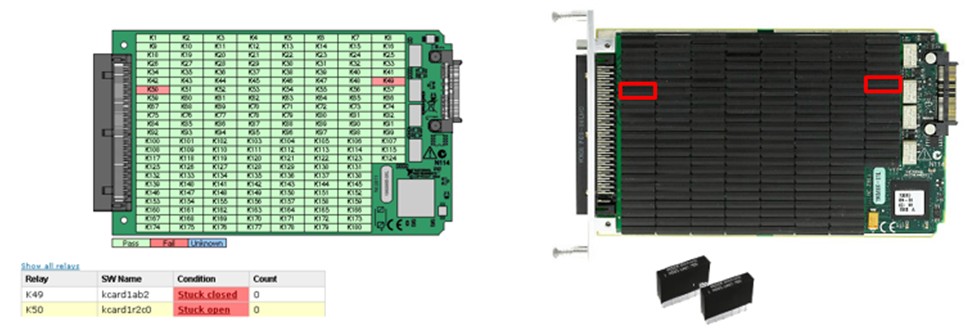

NI PXI switch modules track and store the number of relay cycles onboard the module. You can use the relay count information to predict when a switch module is near the end of its life. With this capability, you can streamline the process of identifying which relays you need to replace and avoid costly downtime.

Certain matrix switches are equipped with the NI Switch Health Center, which is a built-in tool for diagnosing relay failures. The Switch Health Center tests every relay within the specified module and generates a graphical report detailing which relays are stuck open or stuck closed.

Figure 3: The Switch Health Center provides comprehensive maintenance tools for certain matrix switches.

NI also offers several switch modules that use FETs and solid state relays (SSRs). Because these components have no moving parts, they have infinite mechanical lifetimes.

Compliance and Safety

All NI switch modules are recognized by the appropriate certification bodies. Depending on the country, state, or principality, certifications may be necessary for use inside the region. For some certifications, such as CE, compliance can be tested in-house. For many modules, however, additional compliance testing by a third-party certifications body is required.

Figure 4: NI switch modules are always certified for their appropriate voltage levels.

All NI modules with voltage ratings greater than 60 VDC or 30 VAC and 42.2 Vp are considered high-voltage modules. These modules are certified by UL (and VDE or Demko, when necessary) to ensure they meet all safety regulations.

Integration and Support

Along with a wide variety of PXI switches, NI has other PXI-based instrumentation such as oscilloscopes, function generators, and RF generators/analyzers that you can use to build fully integrated automated test systems with system-level services and support. With the NI System Assurance Program, you can receive your PXI system fully assembled and tested, with software installed, and customized documentation for your system. Additional tiers of the NI System Assurance Program extend the standard three-year warranty to either three or five years, ensuring you have repair services for all modules within your PXI chassis. As a billion dollar company, NI can also help you create and maintain long-lasting test systems by providing customized services such as advanced repair options, globally managed spares, preventative maintenance, and life cycle engineering.

Figure 5: The NI System Assurance Program provides a fast and easy way to get your system up and running.

Additionally, NI switch software is optimized for and thoroughly tested in software environments like NI TestStand, LabVIEW, and LabWindows™/CVI, ensuring the best software experience of any PXI-based switch. In addition, NI applications engineers around the globe not only provide local support for issues related to NI switches, but can also help troubleshoot other issues related to NI PXI products and NI software. By providing support for the other hardware and software components within your test system, NI simplifies the initial development experience and ensures your system stays up and running.

Superior Software Support

NI provides comprehensive switching software tools that offer a range of functionality, from interactively opening and closing relays to developing application-level software that interacts with test management software. Additionally, the NI-SWITCH driver provides a consistent software experience with other instrument drivers from NI, giving you the ability to reuse training and knowledge from programming other instruments.

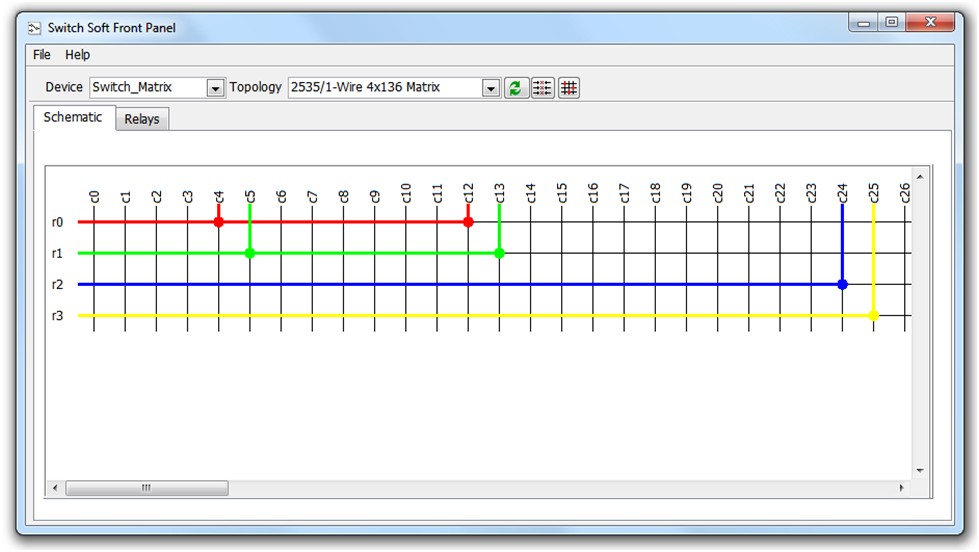

Soft Front Panels

NI switches have an interactive soft front panel that helps you to quickly get up and running with the module and perform basic operations for opening and closing relays. The soft front panel provides real-time status updates of the active switch connections and gives you the ability to monitor and edit relay connections during a test execution. Additionally, you can access the onboard relay count through the switch soft front panel to see how many times each relay has been actuated over the course of its lifetime.

Figure 6: The soft front panel provides interactive control of relays within the switching module.

Programming in LabVIEW or LabWindows/CVI

NI PXI switches are programmed with the NI-SWITCH driver, which provides a consistent driver and programming interface for all NI switches, regardless of module or topology. The NI-SWITCH driver is optimized for programming environments such as LabVIEW, LabWindows/CVI, and NI Measurement Studio. The tight integration in both development and testing ensure that NI switches provide a superior user experience to third-party instrument drivers. The following list details some of the software features of NI switches:

- Built-in measurement palettes

- Example programs for getting started

- Detailed, integrated LabVIEW Help

- Thorough error handling and messaging

Figure 7: Example programs in the NI-SWITCH and NI-DMM drivers show you how to use the switch with other instruments.

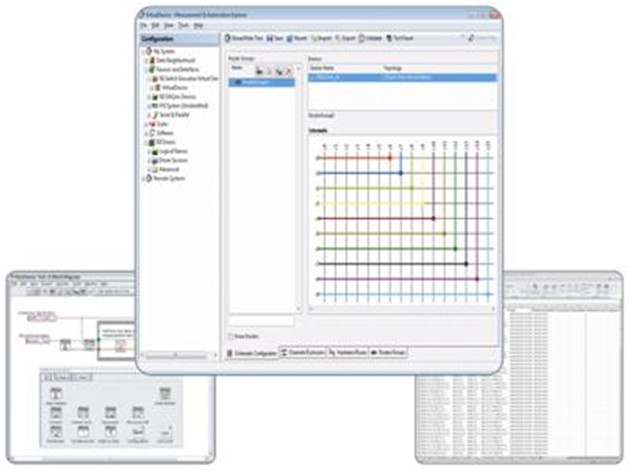

NI Switch Executive

In addition to these basic programming APIs, NI provides a software programming package called NI Switch Executive to abstract switch programming and thus accelerate the development of your system. NI Switch Executive offers the following capabilities:

- Aliasing: Dealing with thousands of channels without abstraction is confusing and time consuming. With the Aliasing feature, name your channels and routes intuitively to simplify programming.

- Graphical Configuration: The Graphical Route Configuration Utility for NI switches makes configuration a simple point-and-click operation. Use switch illustrations instead of text fields to create individual routes or route groups. You can also customize the channel names and define hardwired channels from this interactive utility.

- Excel Integration: Using the import/export feature, you can export your virtual device to file and open it in Microsoft Excel. From there, edit your configuration and expand your channel count using the text-editing features and advanced formulas. When you are satisfied with your changes, you can import your configuration back to a new or existing virtual device. With the text-editing features of Excel, you save significant programming time.

Figure 8: NI Switch Executive adds abstraction and saves programming time.

In addition, NI Switch Executive simplifies your switch code maintenance through interactive debugging, validation, and reporting tools, and provides APIs for LabVIEW and LabWindows/CVI. You can also natively call NI Switch Executive routes and route groups from NI TestStand, which simplifies development and maximizes the code reuse of your automated test system. NI Switch Executive and NI TestStand are two of the automated-test-specific software tools in the NI Automated Test Option to the NI Developers Suite Core Package.

Benefit From the Right Switch

At both a module and system level, NI PXI switches offer benefits ranging from tools that help you increase throughput and development efficiency to tight integration with other instruments within the PXI chassis. Additionally, NI provides a comprehensive software experience to help you to quickly get up and running and develop and maintain long-term test systems. Hundreds of different switching topologies, with a variety of relay types and I/O specifications, are in the PXI form factor.

The mark LabWindows is used under a license from Microsoft Corporation. Windows is a registered trademark of Microsoft Corporation in the United States and other countries.