Measuring Load with Bridge-Based Sensors

This document provides information to help you understand fundamentals of load measurements and how different sensor specifications impact load cell performance in your application. After you decide on your sensors, you can consider the required hardware and software to properly condition, acquire, and visualize load measurements. You can also consider any extra signal conditioning you may need.

What are Force and Load?

Force is the measure of interaction between bodies: for every action there is an equal and opposite reaction. Force is also described as a push or pull on an object. It is a vector quantity with both magnitude and direction.

Load is a term frequently used to refer to the force exerted on a structure or body. The SI-recognized unit for force or load is the Newton (N). Load cells directly measure force or weight. These transducers convert mechanical force into electrical signals by measuring deformations produced by the force or weight. A common application of these devices is measuring dry or liquid materials in a hopper. A measure of the weight through a load cell yields a measure of the quantity of the material in the hopper.

Measuring Load

The way to measure load is through a load cell. Different types of load cells operate in different ways, but the most commonly used load cell is the strain gage load cell. In general, you use a beam or yoke assembly that has several strain gages mounted in a Wheatstone bridge configuration so that the application of a force causes a strain in the assembly the strain gages are measuring. Generally, these devices are calibrated so that the force is directly related to the resistance change. Less commonly used pneumatic and hydraulic load cells translate force into pressure measurements. When force is applied to one side of the piston or diaphragm, the amount of pressure (pneumatic or hydraulic) applied to the other side to balance that force is measured. This rest of this white paper focuses on strain gage or bridge-based load cells.

The most critical mechanical component of a load cell or strain gage transducer is the structure (spring element). The structure reacts to the applied load and focuses that load into an isolated, uniform strain field where strain gages can be placed for load measurement. The three common load cell structure designs—multiple-bending beam, multiple column, and shear web—form the basic building blocks for all possible load cell profiles and/or configurations.

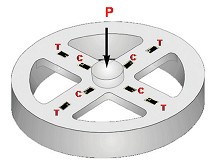

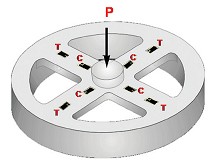

Multiple-Bending Beam

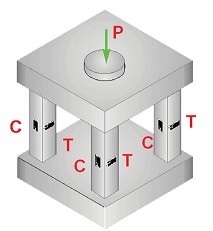

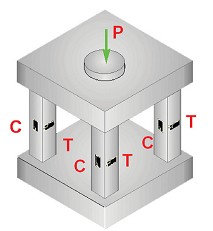

Multiple Column

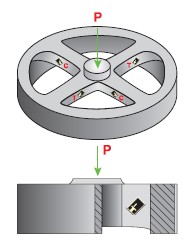

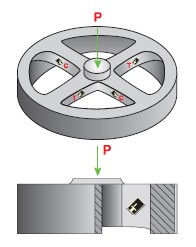

Shear Web

Figure 2. Load cell structure designs mount strain gages to measure compression and tension in different ways. [1].

Multiple-bending beam load cells are low capacity (20 to 22K N) and feature a wheel-shaped spring element that is adaptable to low-profile transducers. It contains four active gages or sets of gages per bridge arm, with pairs subjected to equal and opposite strains (tension and compression).

Multiple-column load cells consist of multiple columns for higher capacity (110K to 9M N). In this arrangement, each bridge arm contains four active strain gages, with two aligned along the principal axis of strain and the other two in the traverse direction to compensate for Poisson’s effect.

Shear-web load cells have a medium capacity (2K to 1M N) and use a wheel form with radial webs subject to direct shear. The four active strain gages per bridge arm are bonded to the sides of the web, 45 degrees to the axis of the beam.

| Multiple-Bending Beam | Multiple Column | Shear Web |

|

Choosing the Right Load Cell

Load cells operate in two basic modes: the compression mode, during which the weighing vessel sits on one or more load cells, or the tension mode, during which the weighing vessel hangs from one or more load cells. You can design the different load cell structure configurations discussed in the previous section using any of these configurations for compression-only forces, or you can design them to measure both a tension and compression force.

Beyond the principal measurement, you select a load cell primarily based on capacity, accuracy, and physical mounting constraints or environmental protection. You cannot determine expected performance by any one factor. You must pinpoint it through a combination of different sensor parameters and the way you designed the load cell into your system. Refer to the table to compare the range, accuracy, sensitivity, and price of different load cell types.

| Load Cell Sensors | Price | Weight Range | Accuracy | Sensitivity | Comparison |

| Beam style | Low | 10 – 5k lb | High | Medium |

|

| S Beam | Low | 10 – 5k lb | High | Medium |

|

| Canister | Medium | Up to 500k lb | Medium | High |

|

| Pancake/Low Profile | Low | 5 – 500k lb | Medium | Medium |

|

| Button and Washer | Low | Either 0 – 50k lb or 0 – 200k lb | Low | Medium |

|

Capacity—Define your minimum and maximum capacity requirements. Be sure to select the capacity over the maximum operating load and determine all extraneous load and moments before selecting a load cell. The load capacity must be capable of supporting the following:

- Weight of the weighing structure (dead load)

- Maximum live load that can be applied (including any static overload)

- Additional overload arising from external factors such as wind loading or seismic activity

Measurement frequency—Load cells are designed for general-purpose use or are fatigue-rated to withstand millions of load cycles with no effect on performance. General-purpose load cells are designed for static or low-cycling frequency load applications. They typically survive up to 1 million cycles depending on the load level and transducer material. Fatigue-rated load cells are typically designed to achieve 50 million to 100 million fully reversed load cycles, depending on the load level and amplitude.

Physical and environmental constraints—One of the key characteristics to consider is how you are integrating the load cell into your system. Identify any physical restrictions that limit size (width, height, length, and so on) or the way the load cell can be mounted. Most tension and compression load cells feature center female threads on top and bottom for fixturing, but they also may have male threads or a mixture of both. Consider how the system will operate and what the worst-case operating conditions may be—the widest temperature range, the smallest weight change required to be measured, the worst environmental conditions (flood, tempest, seismic activity), and the maximum overload conditions.

Signal Conditioning for Load Cells

Load cells can be either conditioned or nonconditioned. You can connect conditioned sensors directly to a DAQ device because they contain the required components for filtering, signal amplification, and excitation leads along with the regular circuitry for measurement.

If you are working with nonconditioned sensors, you must consider several signal conditioning elements to create an effective bridge-based load measurement system. You may need one or more of the following things:

- Excitation to power the Wheatstone bridge circuitry—learn more in the measuring strain resource

- Remote sensing to compensate for errors in excitation voltage from long lead wires

- Amplification to increase measurement resolution and improve signal-to-noise ratio

- Filtering to remove external, high-frequency noise

- Offset nulling to balance the bridge to output 0 V when no strain is applied

- Shunt calibration to verify the output of the bridge to a known, expected value

To learn how to compensate for these errors and review other hardware considerations for bridge-based load measurements, download the Engineer's Guide to Accurate Sensor Measurements.

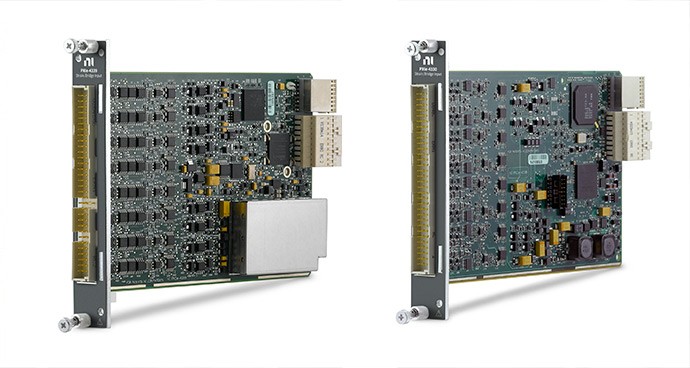

Connecting Load Cells to NI Hardware

After you know your sensor or test needs, deciding on the hardware to collect that data is the next important step. The acquisition hardware quality determines the quality of the data you collect.

NI offers a range of strain and force hardware that is designed to acquire load data and is compatible with a variety of load bridge-based sensors.

Simple Hardware Setup

Pair Your Load Cell with Recommended Hardware

The CompactDAQ Strain and Load Measurement Bundle simplifies connecting your load cell with a bundle of strain/bridge input module(s) and a CompactDAQ chassis.

Other Products for Measuring Load

The following products can interface with load cells. These products also work pressure, force, and torque measurements. Learn more about measuring pressure with bridge-based or other pressure sensors, strain with strain gages, or torque with bridge-based sensor to choose the right sensors and use with NI products.

| Method | Frequency Limit |

| Handheld | 500 Hz |

| Magnetic | 2,000 Hz |

| Adhesive | 2500 to 5000 Hz |

| Stud | > 6000 Hz |

References

- FUTEK Advanced Sensor Technology, Inc., “How a Load Cell Works.” [online] Available at: https://www.futek.com/how-a-load-cell-works [Accessed 6 Oct 2022]

- PCB Piezotronics, Inc., http://www.pcb.com/linked_documents/force-torque/catalog/sections/ftq200g_0107_6.pdf

- S. Himmelstein And Company, “Choosing the Right Torque Sensor.” [online] Available at: https://www.himmelstein.com/sites/default/files/2018-10/B705.pdf. 2013.