NI PXI Embedded Controller Design Advantages

Contents

- Overview

- Performance

- Increased Memory and Hard Drive Offering

- High Reliability

- Fast System Recovery

- Flexible Software: Operating System Options

- Data Security

- Longevity: Solutions for the Long Term

- Next Steps

Overview

PXI embedded controllers from NI provide a high-performance, yet compact in-chassis embedded computer solution for your PXI Express (PXIe) measurement system. A PXI embedded controller provides everything you’d need to run your PXI system without an external PC and acts as the central processing and control hub for all instruments within a PXI system. In this paper, learn about the NI design features that give NI the ability to deliver highly reliable, high-performance controllers including:

- Partnering with processor manufacturers to integrate the latest technology into our embedded controllers for the highest performance.

- Supporting operating conditions in extreme temperatures, 24/7 operations, and offering a real-time OS option for improved system dependability to ensure high reliability.

- Providing flexible OS options that come pre-configured and the ability for factory installation of application software and device drivers, supporting everything from benchtop DUT validation to long-term test stations.

- Offering various service plans and committing to a standard set of peripheral I/O to ensure new embedded controllers are a close drop-in replacement for previous generations, ensuring long-term support.

Performance

NI has been in the business of releasing PXI embedded controllers for more than 25 years. The company has developed a close working relationship with key processor manufacturers such as Intel and Advanced Micro Devices (AMD). For example, NI (as Emerson Test & Measurement) is a Titanium Member of the Intel Partner Alliance, which offers access to the latest Intel product roadmaps and samples. With these relationships, when NI releases new PXI embedded controllers, they utilize the same recently released desktop CPUs that major computer manufacturers use for their products. This trend illustrates NI’s design expertise and commitment to providing the instrumentation industry with high-performance PXI embedded controllers that take advantage of the latest technologies, such as the Intel Core i7 or Xeon processors. Also, in addition to computing performance, I/O bandwidth plays a critical role in designing instrumentation systems. As modern test and measurement systems become more complex, there is a growing need to exchange more and more data between the instruments and the system controller. With the introduction of PCI Express (PCIe) and PXI Express (PXIe), NI embedded controllers have met this need and deliver up to 24 GB/s of system bandwidth to the PXI Express chassis backplane.

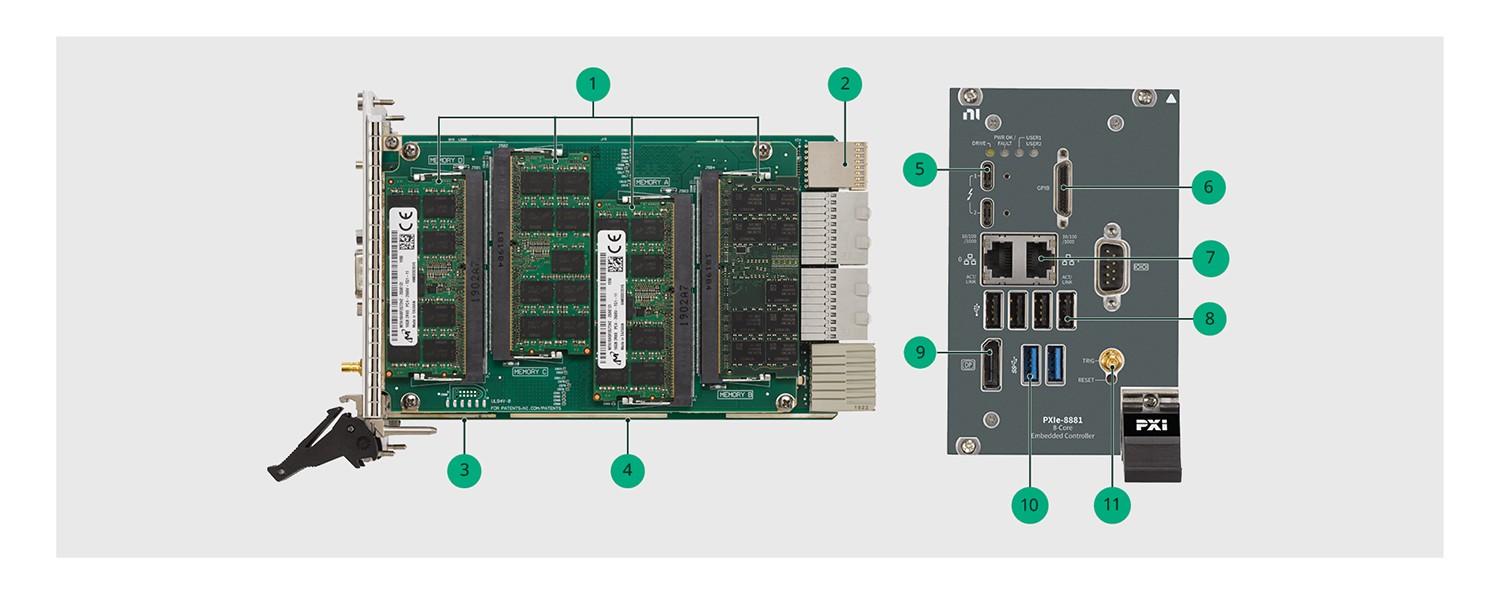

Figure 1: The NI PXIe-8881 Embedded Controller, featuring the 18-core Intel Xeon processor, is ideal for high performance, high throughput, and computationally intensive test and measurement applications.

As the PCI Express standard evolved to PCI Express 3.0, PXI Express continued to take advantage of new features. The NI PXIe-8881 embedded controller uses the advancements of PCI Express technology to offer one X8 and one X16 Gen 3 PCI Express links for interfacing to the PXI chassis backplane.

Using the NI PXIe-8881 embedded controller with a PXI Express chassis, such as the NI PXIe-1095, provides total system data throughput from of 24 GB/s. With this high bandwidth, you can now easily implement computationally intensive applications that demand high-throughput rates such as next generation wireless communication design and prototyping and RF record and playback.

Increased Memory and Hard Drive Offering

As the needs of test, measurement, and control applications evolve, NI continues to expand the accessories portfolio of the PXI embedded controller to ensure optimal performance. For memory-intensive applications, NI offers embedded controller memory upgrade options up to 64 GB RAM.

Not only can you choose from memory upgrade options, but NI also provides a variety of hard drive upgrade options. These options range from high-capacity standard hard disk drives (HDD) to solid-state drives (SSD). When storing instrumentation data from your application, it is convenient to store to the onboard HDD on the embedded controller. To ensure enough space for all desired data, NI offers an option to upgrade your standard HDD to a larger capacity HDD to maximize storage space.

Often to deploy test and measurement systems in classified areas, you need these systems to have an associated declassification process. Declassifying a PXI system requires knowledge of all memory components in the system including the chassis, controller, and modules. PXI embedded controllers feature nonvolatile storage in the form of a hard drive or a flash drive that retains user and system information, even after the system is powered down. Because nonvolatile storage is required for the PXI embedded controller to operate, the NI PXIe-8862 with removable hard disk drive (RHDD) offers the ability to remove this storage media so that it can be placed in a secure environment. In addition, the NI PXIe-8862 RHDD embedded controller adds the ability to have separate, unique software images loaded onto the same station hardware.

Figure 2: Easily access the hard drive through the front panel accessible hard drive carrier for removable storage options.

For harsh environments where you want to operate the controller or store data, SSDs are also available. These drives do not have any moving parts; therefore, they significantly reduce risk due to mechanical failure, resulting in improved system reliability. They can also withstand extreme shock, high altitude and vibration, and other harsh operation environments. Besides better tolerance for harsh operating environments and increased reliability, SSDs provide lower read and write seek times compared to standard rotating medium hard drives. This translates to higher sequential and random data read and write rates. Applications using SSDs experience faster application load times and overall test-time savings due to faster file I/O.

High Reliability

It is critical to ensure that modern instrumentation systems are highly reliable under demanding operating conditions. For this reason, NI offers extended-temperature and 24/7 operation versions of its PXI embedded controllers. These embedded controllers use a more rugged hard drive designed for reliability in low- and high-temperature extremes, with a 100 percent duty cycle and 24/7 operation. The hard drives used in standard versions of these embedded controllers work in an operating range of 5 °C to 50 °C and can operate at 20 percent duty cycle for eight hours a day, five days a week, similar to PCs and laptops. The extended-temperature and 24/7 operation versions have an operating temperature of 0 °C to 55 °C and can be used for applications that require continuous operation, with up to 100 percent duty cycle, for 24 hours a day, seven days a week. You can also choose a solid-state hard drive instead of a rotating hard drive to further improve the reliability of the entire system, particularly in harsh environments. Because of this unique design consideration by NI, you can deploy PXI-based instruments in more challenging applications.

PXI embedded controllers continuously feature the latest processors on the market. To ensure the embedded controller offers optimal performance over the entire operating range, NI performs extensive thermal, mechanical, and electrical testing to ensure that the CPU in an NI PXI embedded controller doesn’t throttle its processor performance when used in extreme environments. Ensuring the CPU’s proper performance and reliability increases the overall reliability of the PXI system. NI accomplishes this by using its expertise in developing embedded controllers and applying techniques such as advanced design simulation and designing custom heat sinks.

To ensure determinism and offer even higher reliability, NI offers PXI embedded controllers that run a real-time OS, NI Linux Real-Time, and NI LabVIEW Real-Time Module software instead of standard Windows OSs. Systems running Windows or other general-purpose OSs cannot guarantee the completion of a certain task in a specified time because the OS shares the processor with other system processes running in parallel. With NI Linux Real-Time running on the embedded controller, the entire processor is dedicated to running your specific application, which ensures deterministic and reliable behavior.

Fast System Recovery

In the unlikely case of an embedded controller hardware malfunction, the design of the NI embedded controller allows for quick field replacement of critical components such as the hard drive and the memory without affecting the warranty. To recover faster from a software malfunction, all Windows-based PXI embedded controllers from NI contain a hidden partition that holds a factory-state image of the hard drive. You can use this image to quickly restore the controller to its factory installation state. With the newer controllers, you have the ability to create custom images of the hard drive that you can use later, instead of the default factory image, to recover from a software crash. These NI PXI embedded controller features help reduce system downtime and ensure maximum productivity of a PXI-based automated test or instrumentation system.

Along with system recovery, to improve the serviceability of the PXI embedded controller you can quickly access in-ROM diagnostics for the hard drive and memory without requiring external third-party tools. By running these diagnostics, you can determine if you need to replace the hard drive or memory. The controller design allows for quick field replacement of critical components such as the hard drive and the memory without affecting the warranty. To ease the process of purchasing spare components, hard drive and memory upgrades are available with the embedded controller. Therefore, combining all these features significantly improves embedded controller serviceability.

Flexible Software: Operating System Options

NI PXI controllers support several operating systems including windows OS, real-time OS, and no OS options based on your applications’ needs.

- Windows: Used for a wide variety of applications, windows provide a reliable, versatile, and user friendly operating system. Most controllers come with Windows 10 or 11 preinstalled on the controller to get started quickly.

- NI Linux Real Time: This is a specialized OS designed for real-time applications. It provides deterministic performance and is commonly used in control and automation systems and can be programmed with LabVIEW Real-Time Module software. The LabVIEW Real-Time Module is a software add-on for NI LabVIEW that you can use to create and deploy reliable, stand-alone applications that execute on embedded hardware devices.

- No OS: You can also purchase a controller with no OS installed and install your own Linux distribution, such as Ubuntu or Red Hat Enterprise Linux, which are supported by NI software and drivers.

These controllers also support development environments including LabVIEW, C/C++, C#/.NET, and Python. NI offers online resources on topics such as integrating languages with LabVIEW and using Python with NI hardware and software. Additionally, all PXI embedded controllers are delivered with PXI Platform Services installed. With this NI driver, you can monitor the health of your PXI controller including temperature, CPU load, memory, and disk capacity, among others.

Data Security

The trusted platform module (TPM), a secure cryptoprocessor, is a component on select embedded controllers specifically designed to elevate platform security above the capabilities of today’s software by providing a protected space for key operations and other security-critical tasks. Using both hardware and software, the TPM protects encryption and signature keys at their most vulnerable stages—operations when the keys are being used unencrypted in plain-text form. The TPM is specifically designed to shield unencrypted keys and platform authentication information from software-based attacks. The NI PXIe-8881 and NI PXIe-8862/42/22 models are all equipped with TPM 2.0, the latest version (shown as #3 in Figure 3).

1. 64 GB of DDR4 RAM | 2. High-Bandwidth Streaming | 3. Secured with TPM v1.2 | 4. Up to a Xeon 18-Core Processor | 5. Two Thunderbolt™ Ports | 6. GPIB Port | 7. Two Gigabit Ethernet Ports | 8. Four USB Ports | 9. Display Port | 10. Two USB 3 Ports | 11. External SMB Watchdog/Trigger

Figure 3: The PXIe-8881 embedded controller, featuring processor options up to a Xeon 18-Core, is ideal for high-performance, high-throughput, and computationally intensive test and measurement applications.

Longevity: Solutions for the Long Term

In 1965, Gordon Moore, cofounder of Intel, empirically stated that the transistor count on an integrated circuit would double every 24 months. This prediction, now known as Moore’s Law, has so far been upheld by chip manufacturers such as Intel and AMD and has resulted in an exponential increase in the number of transistors on a single silicon chip.

This rapid increase has directly led to consistent introduction of newer, faster, and more efficient processors every year. Although PXI-based instruments stand to gain from these advancements, be wary of the fact that the introduction of a new processor directly relates to the obsolescence of an older one.

To minimize the impact of obsolescence, NI is committed to ensuring an embedded controller is available to the market on average five years. If an extended support period is required, the NI Services team can work with you to create service plans that meet your specific support needs. Plans can include services such as sparing and rapid replacements; long-term repair and calibration (beyond the product’s commercial end of life); annual lifecycle and obsolescence reports; and technology refresh planning with NI technical resources. For those applications that can migrate to the latest technology, NI is committed to offering a standard set of peripheral I/O—for example USB, Ethernet, GPIB, and serial—to ensure that new embedded controllers are a close drop-in replacement for previous-generation products. Therefore, while designing an embedded controller, it is imperative to choose a processor that offers the best performance and guarantees availability throughout the life of the controller.

NI uses its close and long-term working relationship with the two major processor manufacturers to choose processors and chipsets for PXI embedded controllers with long-term roadmaps. This ensures that these components are readily available throughout the life of the controllers and for any required repair or replacement. This ultimately adds value to the embedded controller and increases the life of the overall PXI-based instrumentation system.

In conclusion, PXI embedded controllers from NI offer a high-performance, compact solution for your test systems. Acting as the central processing and control hub, these controllers eliminate the need for an external PC. NI’s design features ensure reliability and performance through the integration of the latest technology in partnership with processor manufacturers, support for extreme operating conditions, and 24/7 operation with a real-time OS options. With our partnerships and long term commitment to a standardized platform, NI PXI controllers provide a high performance and flexible approach for test and measurement needs.

Next Steps

- Learn more about PXI timing and synchronization

- Configure a PXI system

- Learn about the fundamentals of building a test system

Linux® is the registered trademark of Linus Torvalds in the U.S. and other countries.