NI 데이터 수집 디바이스 또는 시스템 선택 방법

개요

다음 데이터 수집 (DAQ) 어플리케이션에 가장 적합한 솔루션을 찾고 있다면 NI가 제공하는 여러 옵션을 고려해보십시오. 고정된 기능을 제공하는 플러그 앤 플레이 USB 또는 PCI Express DAQ 디바이스부터 아날로그, 디지털 및 센서별 입출력을 조합할 수 있도록 설정 가능한 데이터 수집 시스템에 이르기까지, 모든 요구 사항을 충족할 수 있습니다. 어떤 옵션을 선택하든, 소프트웨어는 데이터 기반 비즈니스 결정을 내릴 수 있도록 실제 입력 데이터를 화면상의 시각적 도구에 연결하는 데 매우 중요한 역할을 합니다. 이러한 구성 요소를 자세히 살펴보고 다양한 데이터 수집 방식을 비교하고 각 방식의 장단점을 논의해 보십시오. 어플리케이션별 솔루션이 필요하다면 NI가 제공하는 자동차용 HIL(Hardware-In-the-Loop) 테스트, 산업 기계용 데이터 로깅 또는 항공 우주 및 국방용 전자기계 시스템 테스트 등의 어플리케이션을 위한 다양한 솔루션을 살펴보십시오.

내용

데이터 수집 디바이스를 사용해야 할 때

데이터 수집 장치는 전압과 펄스 트레인을 읽고 디지털 라인을 제어하는 등 여러 작업을 할 수 있는 아날로그 및/또는 디지털 I/O 채널을 추가하여 PC를 측정 시스템으로 바꾸어 줍니다. 데이터 수집 장치는 전압 측정용 장치와 같이 단일 기능만 제공하는 장치와 아날로그 및 디지털 I/O와 카운터/타이머 기능과 같은 다양한 유형의 I/O를 결합하는 다기능 장치로 나눌 수 있습니다. 데이터 수집 장치는 정해진 기능을 제공하므로 요구 사항이 변경되지 않고 확장성을 요구하지 않는 프로젝트에 가장 적합합니다. 측정 어플리케이션의 종류에 따라 편의성이 필요하면 USB 폼 팩터를 사용하고, 대역폭과 낮은 지연시간이 필요하면 PCI 또는 PCI Express 폼 팩터를 사용하면 됩니다.

대부분의 NI 데이터 수집 디바이스는 바로 측정을 시작할 수 있는 대화식 소프트웨어인 FlexLogger Lite와 함께 제공되며, 어떤 하드웨어에도 완벽하게 연결하여 빠른 측정, 데이터 기록 및 분석을 수행할 수 있습니다. 또한 NI 데이터 수집 디바이스는 LabVIEW와 완전히 연결되고 MathWorks MATLAB®과 Simulink®를 위한 Data Acquisition Toolbox를 통해 MathWorks MATLAB® 소프트웨어에도 직접 연결할 수 있습니다. 게다가 모든 NI 데이터 수집 디바이스를 지원하는 NI-DAQmx 드라이버를 사용하면 Python, C# .NET 및 ANSI C를 사용하여 측정을 수행하고 제공된 예제를 어플리케이션에서 활용할 수 있습니다.

FlexLogger Lite

NI 하드웨어 및 소프트웨어로 데이터 수집 시스템을 구축하는 방법

DAQ 시스템이라고도 하는 데이터 수집 시스템 (DAS)은 개발 과정에서 조기에 설계를 검증하고 제품 결함을 식별하는 데 도움이 됩니다. 하루에도 수천 개, 아니면 수백만 개가 될지도 모르는 제품이 개발되고 있는데, 얼마나 많은 종류의 측정 시스템이 있을지 생각해 보십시오.

NI 데이터 수집 시스템은 모듈형 하드웨어를 기반으로 설계되어 특정 요구 사항에 부응하는 혼합 측정 시스템을 자유롭게 구축할 수 있습니다. 두 가지 주요 하드웨어 접근 방식을 고려해봐야 하지만, 소프트웨어에 대한 옵션은 프로그래밍을 할 필요 없이 설정 가능한 데이터 수집 어플리케이션 소프트웨어인 FlexLoggerTM부터 Python, C# .NET 및 ANSI C와 같은 다양한 프로그래밍 언어까지 다양하며, 이에 더해 LabVIEW와 MathWorks Data Acquisition Toolbox를 사용하는 MATLAB과도 완벽히 통합됩니다.

데이터 수집 시스템

FlexLogger™ 데이터 수집 소프트웨어

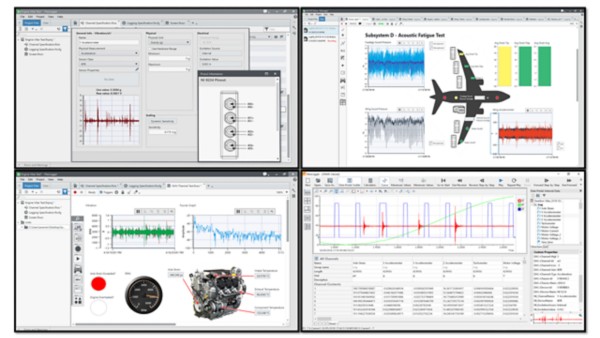

FlexLogger 데이터 수집 소프트웨어는 설치에 드는 시간을 최소화하고 필요한 측정값을 얻는 데 집중할 수 있게 합니다. FlexLogger는 센서 중심의 메뉴 기반 작업 흐름을 통해 아날로그 센서, 디지털 I/O, 자동차 네트워크 등을 결합할 수 있는 유연한 측정 시스템을 제공합니다. 타사 하드웨어 또는 사용자 정의 분석 기능을 플러그인으로 통합하면 FlexLogger 소프트웨어의 기능을 확장할 수 있습니다.

FlexLoggerTM 소프트웨어는 교정, 경보 기능과 화면에 시각적 구성 요소를 끌어서 놓는 방식을 기반으로 시각적 인터페이스 사용자 정의를 지원합니다. 하나 또는 여러 파일에 데이터를 저장하는 기능, 키 입력 또는 알람 트리거를 기반으로 로깅을 시작하는 기능, 테스트에서 메타데이터를 가져와 데이터 관리를 단순화하는 기능을 통해 데이터 로깅 방법을 완벽하게 제어할 수 있습니다. FlexLogger 데이터 뷰어에 기록된 데이터를 볼 수 있으며, 이 데이터 뷰어는 여러 센서와 수식 채널의 데이터를 시각화하여 데이터에 대한 통찰력을 더 빨리 얻을 수 있도록 합니다.

FlexLogger 데이터 수집 어플리케이션 소프트웨어

CompactDAQ 하드웨어

CompactDAQ는 CompactDAQ 섀시와 C 시리즈 I/O 모듈로 구성된 휴대 가능하고 유연한 데이터 수집 솔루션입니다. 섀시당 최대 14개의 I/O 모듈을 설치할 수 있으며 확장성과 유연성이 중요한 다양한 측정 유형이 혼합된 어플리케이션에 이상적입니다. 이더넷 CompactDAQ 섀시는 네트워크를 통한 동기화를 지원하여 여러 섀시를 서로 긴밀하게 동기화할 수 있습니다. 견고한 하드웨어 덕분에, CompactDAQ은 현장에 배치되는 채널 수가 많은 분산형 DAQ 어플리케이션에 매우 적합합니다.

C 시리즈 I/O 모듈은 광범위한 입력 및 출력 기능을 포함합니다. 센서에 특화된 모듈로는 사운드 및 진동 측정, 스트레인 게이지, 온도 센서 등을 처리하도록 설계된 모듈이 있습니다. 기타 모듈로는 전압, 전류, 디지털 I/O, CAN과 LIN 같은 자동차 버스 모듈이 있습니다. 이들 모듈은 섀시 백플레인에 연결되어 호스트 PC와 USB 또는 이더넷 프로토콜을 통해 통신합니다.

또한 NI는 온도, 전압, 변형률 또는 사운드 및 진동과 같은 일반적인 센서 테스트 측정에 널리 사용되는 NI CompactDAQ 하드웨어의 사전 구성된 번들을 제공합니다. 이러한 번들에는 CompactDAQ 섀시와 C 시리즈 모듈은 물론 테스트 시스템을 쉽게 시작할 수 있는 모든 관련 액세서리가 포함되어 있습니다.

CompactDAQ 섀시가 있는 C 시리즈 I/O 모듈

PXI 데이터 수집 하드웨어

PXI 하드웨어는 채널 수가 많은 데이터 수집 및 센서 측정 어플리케이션에 대한 모듈식 접근 방식을 제공합니다. PXI 하드웨어는 최대 18개의 슬롯이 있는 섀시, 백플레인에서의 긴밀한 동기화, 섀시 내 컨트롤러 또는 원격 제어 모듈을 통해 외부 PC에 연결하는 기능을 포함하는 독립형 고채널수 데이터 수집 시스템으로 최신 칩이 탑재되어 있고 Windows OS가 설치되어 있습니다.

PXI의 모듈형 하드웨어 방식은 광범위한 어플리케이션을 포괄하는 여러 신호 컨디셔닝 모듈을 제공합니다. LVDT(선형 가변 차동 변압기)에서 ±1~±600V 범위의 아날로그 입력, 아날로그 출력, RTD 및 열전쌍, 사운드 및 진동(DSA) 및 스트레인/브리지 모듈에 이르기까지, 수십에서 수백 개의 채널을 갖는 시스템을 다양한 측정 및 출력 기능을 조합하여 설계할 수 있습니다. 채널이 더 필요하면 여러 섀시를 설치하여 시스템을 확장할 수 있습니다.

PXIe 컨트롤러, 신호 컨디셔닝 모듈 및 섀시

또한 NI는 오실로스코프, 디지털 멀티미터, SMU, LCR 미터 등을 포함하여사전 구성된 NI PXI 인스트루먼트 번들을 제공합니다. 이 번들에는 테스트 시스템을 쉽게 시작할 수 있도록 섀시, 모듈 및 모든 관련 액세서리가 포함되어 있습니다.

데이터 수집 방식을 선택하는 방법

지금까지 데이터 수집에 대한 다양한 접근 방식을 살펴봤으며 이제 추가적인 요소를 고려하여 가장 적합한 접근 방식을 결정하는 방법을 살펴보겠습니다. 플러그 앤 플레이 데이터 수집에서 동기화된 분산 측정, 고채널수 시스템에 이르기까지, 모든 상황에 NI 데이터 수집 제품을 사용할 수 있으므로 단순히 현재 작업의 요구 사항을 벗어나 그 이상의 것도 생각해 보십시오. 향후 프로젝트에서 디바이스 또는 시스템을 재사용하고 싶을 수도 있을 것입니다. 데이터 수집 장치는 동일하게 유지되고 확장할 필요가 없는 작업에 적합합니다. CompactDAQ의 모듈형 접근 방식은 시스템에 채널 또는 측정 유형을 추가하는 데 필요한 유연성과 확장성을 제공합니다. 또한 혼합 측정 또는 분산 어플리케이션에 가장 적합합니다. 마지막으로, PXIe를 고채널수 어플리케이션 또는 고전압 입력 측정용으로 사용하면 모듈형 방식 덕분에 요구 사항에 따라 시스템을 설계하는 한편으로 향후에 확장도 가능합니다.

대부분의 데이터 수집 프로젝트는 고유하지만 비즈니스 의사 결정의 근거가 되는 데이터를 제공합니다. 현재 프로젝트에 적합할 뿐만 아니라 여러 프로젝트에서 재사용되고 확장할 수 있는 접근 방식을 선택하면 조직에 더 큰 가치가 제공됩니다. 시스템 설정은 요구 사항에 따라 결정되고 프로젝트가 바뀌면 요구 사항이 변경되므로, 장기적인 측정 요구 사항을 고려하여 가장 적합한 방법을 결정함으로써 비용 대비 최대 효과를 얻으십시오.

©2020 National Instruments. 판권 소유. National Instruments, NI, ni.com, CompactRIO, FlexLogger, LabVIEW, NI CompactDAQ 및 NI-DAQ는 National Instruments Corporation의 등록 상표입니다. 여기에 언급된 다른 제품과 회사명은 해당하는 각 회사의 상표 또는 상표명입니다. MATLAB® 및 Data Acquisition ToolboxTM는 The MathWorks, Inc.의 등록 상표입니다.