Ensuring Measurement Accuracy in High-Power CompactRIO Systems (cRIO-9081/2)

Overview

The NI cRIO-9081/2 chassis is designed and tested in several mounting configurations over the rated ambient temperature ranges. The varied mounting orientations or configurations can reduce the maximum allowable ambient temperature and can affect the typical accuracy of C Series IO modules in the system. This document will help you achieve the highest measurement quality when using high-power CompactRIO systems that contain a cRIO-9081/2 reconfigurable embedded chassis.

Note: NI will remove support for Phar Lap for cRIO in the NI 2020 Software Release and for PXI in the NI 2022 Software Release. For more information, please see the Phar Lap RT OS EOL Road Map.

Contents

- Module Loading and Installation Requirements

- Meeting Maximum Accuracy Specifications

- Meeting Typical Accuracy Specifications

- Module Exceptions

CompactRIO systems are designed to provide both high-accuracy measurements and industrial ruggedness. From the factory, each analog I/O module is calibrated against an NIST-traceable precision source. Accuracy is guaranteed for at least one year after calibration and each module can be re-calibrated throughout its life. Because CompactRIO systems are also designed for applications with high shock and vibration, the system avoids the use of failure-prone mechanical cooling components such as rotating fans. While CompactRIO system components can safely be used together across the rated temperature range, analog module accuracy is sensitive to heat. The high-performance processors and FPGAs used in the cRIO-9081/2 can contribute additional heat to the system.

For all measurement systems, proper wiring, noise shielding, and grounding practices are essential to achieving high accuracy analog measurements. Assuring proper connectivity and wiring should be the first step when designing a high accuracy measurement system. To assist in designing your system we recommend visiting Measurement Fundamentals.

To help you achieve the specified analog modules accuracy for cRIO systems containing a cRIO-9081/2 we recommend you adhere to the following guidelines:

Module Loading and Installation Requirements

You can increase analog module accuracy by loading the modules into your CompactRIO chassis in an arrangement that separates analog modules from high-power-dissipating modules such as digital output, communications, or motion modules and from other thermally significant system components such as external power supplies, relays, etc. The maximum power dissipation for each module is specified in the module data sheet. Additionally, installations must meet the requirements for space and cabling clearance as defined in the cRIO-9081 or cRIO-9082 mounting requirements.

Meeting Maximum Accuracy Specifications

Maximum accuracy specifications assume a worst case range of component tolerances and a full thermal load on the system (maximum processor and FPGA usage, and a chassis fully loaded with high power modules).

The following table provides mounting configurations where the module maximum accuracy specifications may be achieved.

| Mounting Configuration/Accessory | Mounting Orientation | Maximum Ambient Temperature for Operation |

| NI Panel Mount Kit on Metallic Surface | Horizontal | 0↔55C |

| NI Panel Mount Kit on Metallic Surface | Any | 0↔45C |

| NI DIN Rail Mount Kit | Horizontal | 0↔45C |

| NI Rack Mount Kit(s) | Horizontal | 0↔45C |

| NI Desktop Kit | Any | 0↔45C |

| Un-mounted on desktop | Any | 0↔45C |

| NI Panel Mount Kit on Non-Metallic Surface | Horizontal | 0↔45C |

| Any | 0↔40C | |

| Any configuration not listed | Not Officially Supported | |

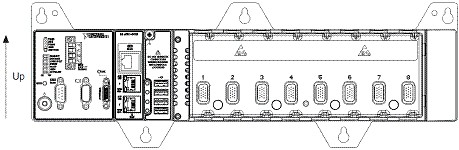

For reference, the figure below shows a cRIO-9081/2 chassis mounted horizontally with an NI Panel Mount kit.

Meeting Typical Accuracy Specifications

The cRIO-9081/2 systems are intended for applications where processor and FPGA performance are critical. Many analog modules provide specifications for typical accuracy. Because the cRIO-9081/2 chassis is a high-power/high-performance system, module typical accuracies cannot be achieved for any specific mounting conditions. Module maximum accuracy specifications may be met as described in the previous section.

Module Exceptions

Thermocouple modules (NI 9211/19)

Thermocouple measurements are more sensitive to thermal gradients because in addition to precise voltage measurements they also require accurate junction temperature measurements. In addition to the NI 9211, 9213, and 9214, the NI 9219 is a universal analog input module that can be used for thermocouple measurements. Because the NI cRIO-9081/2 chassis is a high-power/high-performance system, the maximum accuracy and typical accuracy specification for thermocouple measurements using the NI 9211 and 9219 cannot be achieved for any mounting conditions.

NI recommends using the NI 9213 or 9214 for thermocouple measurements in the NI cRIO-9081/2 chassis. The following table provides mounting configurations where the module maximum accuracy specifications may be achieved for the NI 9213 and 9214.

Mounting Configuration/Accessory | Mounting Orientation | C Series Thermally Sensitive Max Accuracy Specs Achievable |

| NI Panel Mount Kit on Metallic Surface | Horizontal | Yes |

Any | No | |

| NI DIN Rail Mount Kit | Horizontal | Yes |

| NI Rack Mount Kit(s) | Horizontal | Yes |

| NI Desktop Kit | Horizontal | Yes |

Any | No | |

| Un-mounted on desktop | Any | No |

| NI Panel Mount Kit on Non-Metallic Surface | Horizontal | Yes |

Any | No | |

| Any configuration not listed | Not Officially Supported | |

Power quality module (NI 9225)

The modules used to measure power quality provide three specifications: a maximum accuracy specification when used over the full temperature range, a maximum accuracy specification when used at 25C, and a typical accuracy specification when used at 25C. The full temperature range maximum accuracy can be met by following the guidelines in the Meeting Maximum Accuracy Specifications section. Maximum accuracy specifications at 25C and typical accuracy specifications cannot be achieved when used in the NI cRIO 9081/2 chassis for any mounting conditions.

DC servo drive module (NI 9505)

The NI 9505 is a high power full h-bridge brushed DC servo drive module. Because the NI cRIO-9081/2 chassis is a high-power/high-performance system, the published ambient temperature versus current capability for the NI 9505 is not valid. Please contact NI for ambient temperature versus current capability for the NI 9505 for use in the cRIO-9081/82 chassis.