Leading the Way with the Industry’s First Software-Defined Battery Lab

TREND INSIGHT

TRANSPORTATION | 6 MINUTE READ

NI’s Software-Defined Battery Lab solution is disrupting the test industry (again), helping EV manufacturers revolutionize large-scale battery testing with open, enterprise-grade software, modular systems, and expert services.

The history of the automotive industry includes a variety of technological changes that each mark significant advances towards safe, dependable, and consumer-approved vehicles. These historical signposts include the electric starter, the automobile assembly line, automatic transmission, seat belts, and fuel injection, among many others. The electric vehicle (EV)—particularly the EV battery—represents another milestone in that history. The EV battery epitomizes the progress we’ve made in the automotive industry and is integral to the future of electrification.

The demand for reliable and safe EV batteries is ever increasing. Their central place as not only a necessary component within the electric vehicle, but as the most critical innovation in electric vehicles, has brought into sharper focus the need for successful battery testing and production. That need includes safety and reliability in testing, a strategy to go-to-market quickly, and an ability to scale production efforts.

Fundamental to the production of EV batteries in the automotive industry is a successful testing methodology that’s efficient, safe, and scalable. Testing can consume 50 percent or more of product development time. This timeframe needs to be optimized so that all testing procedures and principles can be done efficiently to meet all the demands facing the EV industry, while maintaining high standards of quality.

NI has embarked on a strategy that focuses on the testing stage of EV battery development, which is already creating outstanding results for partners on the front lines. NI’s CEO, Eric Starkloff, at NI Connect 2023 spoke and addressed manufacturers, “For 26 years I’ve been focused on solving a particular problem—how test can improve the performance of your products and your business; how it can be a competitive advantage for you.” With that focus in mind, NI is in the business of disrupting the testing industry (again) through a software-defined approach.

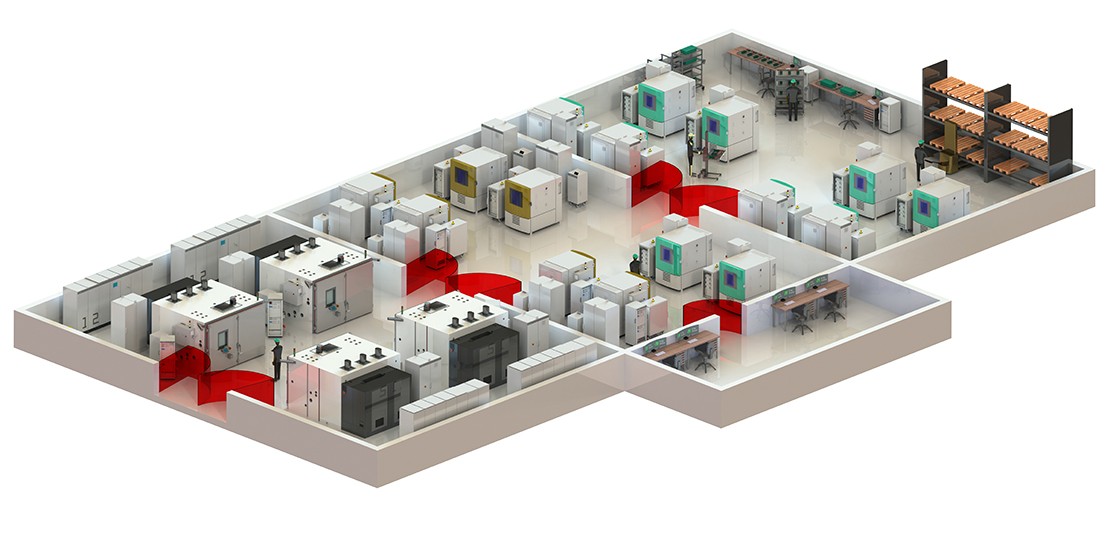

Enter NI’s industry-first software-defined battery lab: a comprehensive solution for large-scale battery testing. It’s comprised of purpose-built, enterprise-grade software, modular and open battery test systems, and expert engineering and integration services. NI’s test leaders are championing this software-defined approach today. These test leaders have discovered that NI’s investments in electrification, comprehensive solution for testing, approach of scalable solutions, and the unique place of the software-defined lab in the industry all make for a strategy that will take EV battery manufacturers to new heights.

At NI Connect, we heard directly from NI leadership on what makes the software-defined battery lab unparalleled in the industry. NI’s mission to offer a flexible, automated, and intelligent test strategy is paying off with enormous dividends. Let’s explore.

Electrification Investments

NI is dedicated to making investments in electrification that will transform the whole industry. It may seem axiomatic that electricity is at the center of this movement of EV vehicles and batteries, and it certainly is. In fact, electrification will change everything as the work of Vision Zero puts electrification front and center to successfully manufacture vehicles with zero emissions. This work will be successful only to the extent that testing is precise and that all parts of a vehicle are working in harmony.

NI’s achievements in supporting electrification have accelerated in recent years to include the acquisition of companies that support test solutions within the software-defined battery lab. This portfolio includes NH Research, Heinzinger Automotive, Kratzer Automation, and SET, among others. By combining software capabilities from these partners and NI’s PXI solution, NI offers fully integrated, comprehensive test system solutions to empower manufacturers with intelligent and automated battery testing and validation.

These investments are key to an evolving vehicle. Components that were once purely mechanical in nature are now controlled by sensors. Semiconductors and sensors are required to deliver battery energy to critical components in a car. One of NI’s test leaders , Allegro Microsystems, a global leader in magnetic sensing and power IC solutions, has benefited from this investment by using NI’s software tools for technologies such as its electromechanical braking application.

Comprehensive Battery Test Solution

A software-defined approach to testing is based on the idea that test is a strategic differentiator that delivers on critical business outcomes. NI Executive Vice President and General Manager of Global Business Units, Ritu Favre, recently identified three critical approaches to test for successful delivery: Automation, standardization, and data analytics—and all are core to NI’s comprehensive solution.

The software-defined lab gives engineers visibility into data across all stages of development—even across facilities and the supply chain—resulting in a global approach. The solution is cloud-based, open, and driven by enterprise-grade software. This kind of customer-specific software offers automated and parallel work that normally would be managed through manual processes. It also offers a more granular approach to testing at the battery cell level, identifying problems with the cell in how it responds to testing. Testers will gather the resulting data and add to the ongoing evolution of analyzing battery cells. This kind of digital transformation in software is critical to moving the EV battery industry forward.

Although standardizing remains a key factor, the flexibility of the software-defined lab is inherently agnostic and accommodating. This agnostic approach makes NI a testing differentiator by allowing the industry to evolve as testing methodologies evolve with it.

Addressing EV Battery Volume

The sheer volume of EV batteries being tested and produced today would have been incomprehensible a decade ago. Production revenues for EV batteries tripled from 2021 to 2022. Manufacturers know the pressure associated with testing and production all too well.

Compounding the challenge of volume is the time it takes to test and validate batteries. Many manufacturers have found that at least 50 percent of development time is taken up by testing—a number that consumes precious development time and exacerbates already challenging production schedules.

Unique to the Industry Methods

In an industry dependent on testing that requires both precision and a quick ramp to production, only a software-defined battery lab that increases the speed of results while maintaining quality is sustainable enough to help EV manufacturers stay ahead of the curve.

It should be clear that this type of battery lab is an unparalleled asset to the ever-collaborating and enormously expanding EV industry. A common acronym in the automotive industry is ACES—Autonomous, Connected, Electrified, and Shared—and NI’s software-defined battery lab can be the game-changing engine to take the industry forward in this vision and the creation of electric vehicles of the future.