Testing Starter Motor Durability Using NI LabVIEW and NI CompactDAQ

Mark Ridgley, Radius Teknologies, LLC

"With LabVIEW and CompactDAQ, Radius Teknologies, LLC developed a custom user interface, data acquisition, data analysis, and data presentation application needed to deliver a reliable and easy-to-use control and measurement application."

- Mark Ridgley, Radius Teknologies, LLC

The Challenge:

Performing durability testing on up to four automotive starter motors in parallel.

The Solution:

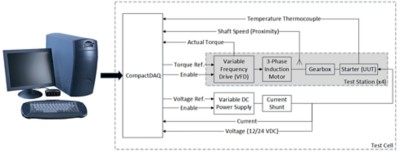

Using LabVIEW system design software and CompactDAQ hardware to develop the user interface, data acquisition, data analysis, and data presentation software needed to deliver a versatile, scalable, and modular control application that met all requirements of the starter durability test system.

Understanding Starter Durability Test Systems

An automotive starter motor must provide years of trouble-free operation. Automotive starter motor manufacturers need a means to verify that their products are capable of meeting this requirement. Testing every unit produced would be time consuming and expensive, so manufacturers typically only test a small sample of the parts produced in a production run to verify product durability.

An automotive starter motor typically operates for five seconds or less, under high loading. Automotive starter manufacturers require a test system that can simulate these operational conditions while simultaneously capturing, analyzing, and logging key unit under test (UUT) and system data, in addition to monitoring test system components for fault conditions.

A single UUT will be subjected to thousands of test cycles to verify its durability. A single test cycle consists of five seconds of run time, followed by a 55-second cool-down period. Because testing each UUT is a lengthy process, a starter durability test system must be versatile, reliable, and easy to use. The test system must fully, reliably, and completely accomplish the following tasks within the five-second run-time window:

- Apply voltage to the appropriate test station

- Engage the starter motor solenoid on the appropriate test station

- Command the motor drive to apply countertorque to the starter motor on the appropriate test station

- Capture and log all measurement data acquired from the appropriate test station

- Repeat the process for the user-selected number of test cycles

The delivered test system consists of four separate test stations, controlled by a single computer system. We implemented the capabilities listed below to meet customer requirements:

- System operation is driven by a spreadsheet file containing starter motor specification data, so the customer can test new part numbers simply by updating the spreadsheet file with the new part number specifications. No modification to system software is required to test new products.

- Test station control software is designed so that each station runs as a separate instance, controlled by the top-level application. Each instance uses a distinct memory location to store its associated data— ensuring data segregation and integrity for all test stations.

- Because the system is required to run up to four test stations in parallel, it must share several key system resources, so the software is designed to prevent resource conflicts. When any test station is using a shared resource, all other test stations must wait until that resource is released.

Equipment Used

Equipment | Description | Function |

cDAQ-9178 | 8-Slot USB Chassis | DAQ Measurement System Chassis |

NI 9205 | 32-Channel, ±200 mV to ±10 V, 16-Bit, 250 kS/s Analog Input Module | UUT Current Measurement |

NI 9221 | 8-Channel, ±60 V, 800 kS/s, 12-Bit Analog Input Module | System Current Measurement |

NI 9263 (2) | 4-Channel, 100 kS/s, 16-bit, ±10 V, Analog Output Module | Drive Reference Voltage |

NI 9422 | 8-Channel, 24 V to 60 V, 250 µs, Sinking/Sourcing Digital Input | E-Stops, Drive Status, Jog Switches |

NI 9472 (2) | 8-Channel, 24 V Logic, 100 µs, Sourcing Digital Output Module | UUT Solenoid Relays, Drive-Enable |

NI 9211 (2) | 4-Channel, 14 S/s, 24-Bit, ±80 mV Thermocouple Input Module | UUT Temperature Measurement |

Emerson Unidrive SP (4) | AC Motor Speed Controller | UUT Torque Loading |

Emerson Commander SK | AC Motor Speed Controller | UUT DC Power Generation |

Table 1: Starter Durability Test System Key Components

Company Background

Radius Teknologies, LLC was established as an NI Partner and independent LabVIEW consulting company in 2013. We are dedicated to helping our customers be successful using NI hardware and software to design, develop, and implement creative, versatile, and sustainable solutions to complex technical challenges in measurement, automation, and control. We have experience designing, developing, and implementing test systems based on NI hardware and software for the academic, consumer, medical, automotive, industrial, and aerospace/military markets.

Achieving Success with LabVIEW and CompactDAQ

Radius Teknologies, LLC has more than 16 years experience developing applications based on LabVIEW. As an NI Partner, we are strong advocates of LabVIEW system design software. LabVIEW is a graphical programming environment with which we quickly produced the intuitive GUIs that this customer required. We were able to quickly prototype and refine the GUIs so that operators can execute tests quickly, with minimal user interaction and a reduced probability for errors.

CompactDAQ is a portable, rugged data acquisition platform that integrates connectivity and signal conditioning into modular I/O for directly interfacing to any sensor or signal. Using CompactDAQ with LabVIEW, developers can customize how measurement data is acquired, analyzed, presented, and managed to meet customer requirements.

LabVIEW and CompactDAQ provide a complete system development platform that provides for maximum reuse and unifies design, validation, and automated test. In addition, the ability to replicate real-world environments for individual vehicle components, coupled with a wide range of I/O and control options and flexible software, uniquely positioned LabVIEW and CompactDAQ as the best choice for this application.

Conclusion

With LabVIEW and CompactDAQ, Radius Teknologies, LLC developed a custom user interface, data acquisition, data analysis, and data presentation application needed to deliver a reliable and easy-to-use control and measurement application that met all customer requirements. The tight integration of NI hardware and software helped us meet all of the software design challenges presented by this demanding application.

The customer required minimum training on how to use the delivered software application, and was able to quickly put the system into service without any significant software issues or downtime. LabVIEW and CompactDAQ were undoubtedly the best choices to meet this customer’s rigorous requirements.

Author Information:

Mark Ridgley

Radius Teknologies, LLC

9401 Inverness Ln. NW

Ramsey, , MN 55303

Tel: 763.438.0322

mark.ridgley@radius-tek.com

An NI Partner is a business entity independent from NI and has no agency or joint-venture relationship and does not form part of any business associations with NI.