HIL Test Systems as a Key Technology for ADAS Validation

Dr. Thomas Herpel, Senior Manager Test System Development, ZF Mobility Solutions, Ingolstadt, Germany

Michael Vogt, Engineering Supervisor, HIL Development, ZF Active Safety GmbH, Koblenz, Germany

Brenda Vargas, Senior Solutions Marketing Manager, Transportation, NI

Case Study Highlights

NI’s open, data-driven, software-connected ecosystem plus PXI capabilities enabled ZF to develop a scalable ADAS HIL system to meet future requirements while keeping up with test programs.

ZF’s ADAS HIL test system prototype was replicated to several systems to operate in a HIL farm, creating fully automated validation systems across numerous software test cycles.

ZF’s team competencies led to the development of powerful modular HIL software libraries, serving as a basis for future projects and a path to become an NI Center of Excellence.

“AD and ADAS require the combination of different test methodologies which is challenging but essential to provide driver and passenger safety and ultimately for AVs to become a reality. With NI solutions, we can build up systems and move one step closer to a comprehensive test strategy consisting of both real-world and virtual test efforts.”

—Dr. Thomas Herpel, Senior Manager Test System Development, ZF Mobility Solutions, Ingolstadt, Germany

The Challenge

The ADAS hardware-in-the-loop (HIL) test system must meet the continuously changing requirements of verification and validation of the advanced driver assistance systems (ADAS) and autonomous driving (AD) complex functions for autonomous vehicles to provide humans with the safety needed.

The Solution

ZF’s ADAS Validation Department worked with NI to develop and tailored a scalable, flexible, and highly networked HIL test system that has been reused for testing ECUs for ADAS and AD systems while saving significant development time.

ZF Next Generation Mobility

As one of the world’s biggest automotive Tier 1 suppliers, ZF committed itself to “vision zero,” which aims for zero traffic accidents with fatalities and zero emissions. One major approach to reach this goal is making driving safer, more efficient, and more comfortable.

ZF’s future strategy focuses strongly on shaping “Next Generation Mobility,” describing viable mobility solutions that are electric, intelligent, connected, sustainable, safe, autonomous, and affordable.

Figure 1: ZF Next Generation Mobility. Photograph Courtesy of ZF Group.

ZF has a strong position in the market with its expertise and product portfolio to enable vehicles to see, think, and act. The maxim “See – Think – Act” summarizes concisely the company’s leading theme. For example, ZF can interconnect cameras and sensor systems—such as radar or lidar, to provide a 360-degree panoramic view (See). In addition, ZF develops, produces, and connects the switching centers of the vehicle using a network of electronic control units or central high-performance computing platforms (Think). And naturally, the company can connect mechatronic systems in the drive, chassis, or steering system to create modern drive functions (Act). This makes vehicles not only safer but improves their efficiency.

Test System Development at ZF Mobility Solutions

ZF Mobility Solutions (ZMS) is a 100 percent subsidiary of ZF Group with its Headquarters in Ingolstadt, Germany. The mission of this portion of the company is to provide clean, efficient, comfortable, and affordable mobility by development and implementation of autonomous transport systems.

The ZMS Test System Development Department’s vision is to develop innovative and high-quality test systems tailored to the specific demands of verification and validation of complex ADAS and AD.

The mission is to build prototypes for HIL-based test systems for ZF Group with hardware, software, and processes ready for use in serial development projects.

ADAS Validation Challenges

Figure 2: ZF ADAS. Photograph Courtesy of ZF Group.

ADAS requires intensive validation at various stages in development. Testing must include real-world scenarios for complex functions that are highly networked. How safe should ADAS be before they are allowed on the road for consumer use? Real car testing requires a lot of time, is expensive, and sometimes provides only limited informational value—especially in terms of reproducibility of tests. While it is still necessary, there is an urgent need to shift from “a quantity of miles driven” to “the quality of the miles that need to be tested on the road” by including other test methodologies into the validation process.

More than ever, a well-elaborated validation strategy is an important pillar of being compliant to state-of-the-art norms and regulations such as the ISO-26262 standard or Automotive SPICE (ASPICE).

Using virtual reality (VR) technologies in development is one of the major trends; it allows for testing the system in earlier stages under realistic conditions. HIL-based test systems for open-loop data replay and closed-loop simulations are particularly suited for validation of ADAS functions on the target hardware and the determination of functional and non-functional key performance indicators (KPIs).

The requirements and combination of different test methodologies are essential to provide driver and passenger safety—and ultimately for autonomous vehicles to become a reality. NI solutions enable test systems to be constructed that contribute to a comprehensive test strategy consisting of both real-world and VR-based test efforts.

Requirements for Radar HIL Test System

ADAS put high demands on test system development as the focus and need for these systems is no longer only on high computing power, but more than ever on scalability, flexibility, and aspects of highly networked system operation. The system-under-test (SUT) is a ZF automotive-graded radar sensor for typical ADAS applications such as adaptive cruise control, collision avoidance, and pre-crash safety systems or copilot functions. As the complexity of the SUT increases, it is inevitable to think in platforms when developing new test systems.

Key aspects of such test systems are:

- Modularity: Plug and play of core HIL and add-on system components

- Scalability: From single ADAS ECU validation to high-performance 360° AD sensor data replay and closed-loop virtual reality simulation

- Dependability: 24×7 serial HIL farm operation with highest availability requirements

- Compatibility: Integration of new HIL test systems into existing eco-systems with respect to group IT infrastructure, existing tools, and processes

- Smooth operability: HIL farm setups for a broad range of serial validation with remote access, operation and maintenance, and diagnosis

For open-loop validation of ADAS ECUs with real-life recordings from proving grounds and test fleets, data reinjection must be enabled with high data rates over complex communication interfaces with a demand for highly accurate timing and synchronization. In addition to recorded radar data, the vehicle rest-bus communication signals must be reprocessed in parallel such as vehicle speed signals, yaw rates, or other status data. For radar data reinjection, the HIL test system must provide the appropriate interfaces and a robust and precise control of reinjection with high I/O data rate and sideband communication. Another key aspect of the HIL test system’s software platform and interfaces is the requirement for full automation of HIL test runs, remote software deployment and HIL operation in 24×7 HIL test farm operations.

Approach

The main drivers for ZMS to go with NI were the high-performance, real-time computing systems together with high-precision timing and synchronization capabilities. The PXI platform was also attractive, with its broad variety of interface cards and modules, such as up-to-date automotive bus system, and analog and digital I/O cards.

NI’s open software platform also allows for generating modular and application-specific software in HIL system development, especially regarding real-time software development with LabVIEW and system operation aspects covered by SystemLink™ software.

The PXI platform supports modularity to switch work from one ADAS project to another without reinventing the wheel. This is achieved by setting up new parameters for each test case and relying on the existing basis of a core system that can be reused to test powerful ECUs for ADAS and AD systems while saving time. And it also brings scalability, as today ECUs with five to ten bus connections and data interfaces can be tested; tomorrow’s tests can be scaled up to 30 interfaces or more.

The complete HIL simulator development included the mechanical and electrical design of the HIL rig, incorporating all aspects of work and product safety.

The configuration of the PXI system was as follows:

- PXIe-1082 chassis

- PXIe-8840 Intel i7 quad core, 8 GB RAM, 320 GB hard drive

- PXI-6683 timing and synchronization module

- 2 x PXI-8512 CAN-FD bus interfaces

Additional HIL system components:

- 19-inch HIL control PC with Ubuntu operating system

- Power supply for 12 V DC

- 16 ampere power inlet

- External MIPI/CSI-2 and SPI re-injection device

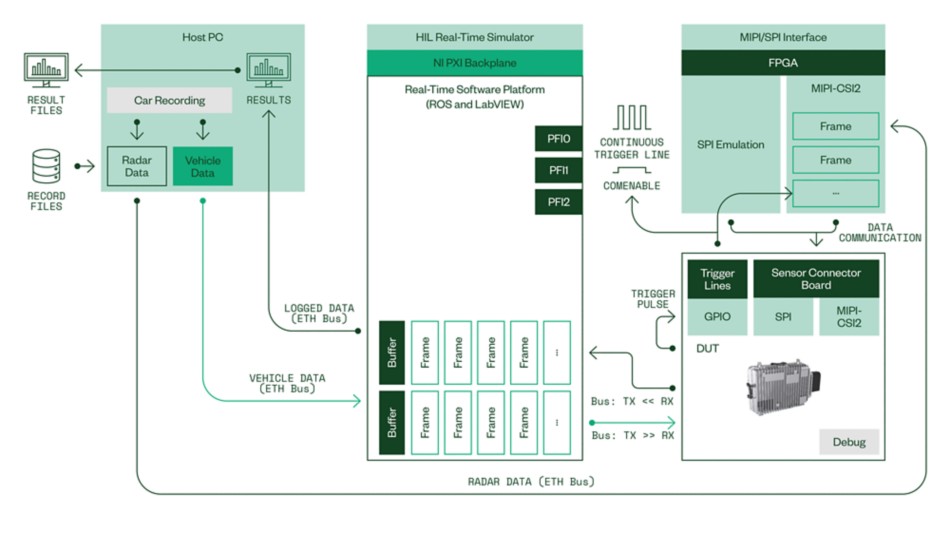

Figure 3: HIL real-time core simulation system

The software architecture for HIL real-time operation and data streaming for re-injection consists of:

- ROS (C++) nodes for processing of the recorded radar data

- LabVIEW components for HIL real-time operation, bus communication, and synchronization

- Scripts and additional software components to enable remote control and operation, and to connect to SystemLink servers

With the respective competencies at ZMS and within ZF Group, NI assisted in establishing processes and maintenance for software. This helped in building up a powerful and modular HIL software library, which serves as a basis for future HIL projects and created a path to become an NI Center of Excellence in 2022.

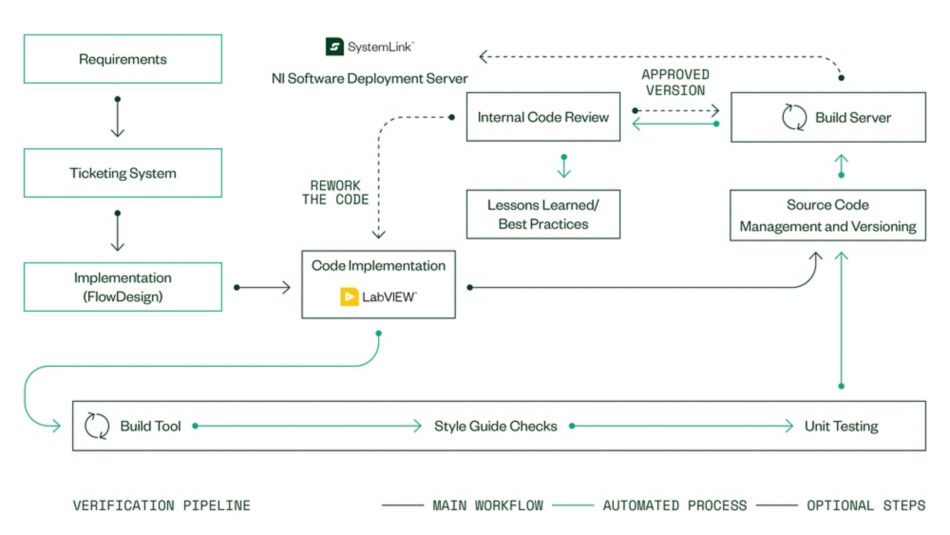

Software development at ZMS relied on existing processes for agile, Scrum-based software development and for continuous integration and continuous deployment (CI/CD), which is depicted in the following figure.

Figure 4: Software Development Process

The following figure provides an overview on the data flows and communication dependencies in the HIL test system setup.

Figure 5: Software Development Process

Results

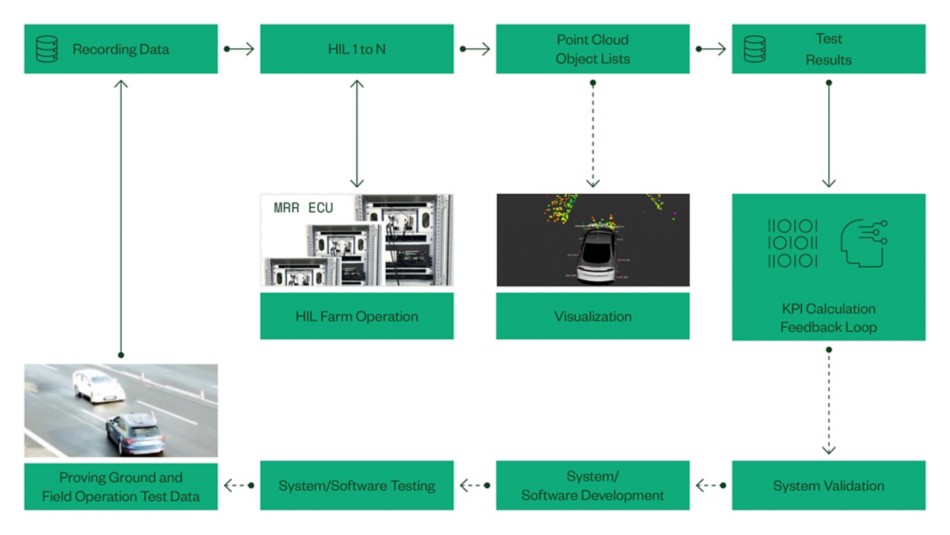

With the HIL system prototype being developed and replicated to several HIL systems operated in a HIL farm, radar system validation was performed across a significant number of radar software test cycles in fully automated HIL runs. This led to both a greater flexibility in on-the-fly testing of new software releases on the target ECU platform and high coverage in testing.

During radar system development, data equivalent to more than 600 days of proving ground test operations was successfully reprocessed in the HIL farm.

The integration of the various HIL test systems as an HIL farm into the system development and validation process is depicted in the following figure.

Figure 6: System Development and Validation Process

The capabilities of SystemLink for remote HIL real-time software deployment, system operation, and maintenance brought an additional benefit when scaling from HIL prototype development to a 24×7 HIL farm. NI’s solutions save ZF time and enable scalability. This means ZF’s test programs can keep pace with their own innovation timeline.

One remarkable achievement during the radar HIL development project was the certification of the Test System Development department at ZMS as an “NI Center of Excellence.” The team was demonstrating engineering excellence and time-saving software development processes, scalable and extensible software design and architecture, as well as consistent training, mentoring, and learning.

Our strategic partnership will also empower us in the future to successfully bring safe and reliable ADAS and AD systems to the market.

ZF Team Impact:

“I have an amazing team with me, who are highly motivated and real experts in what they’re doing and fully committed to our projects and ZF’s strategy. Together with our strategic partners such as NI, we bring our ideas successfully into reality.”

Dr. Thomas Herpel, Senior Manager Test System Development, responsible for setting the conditions so the team can do their best job and bring ZF strategy to the market today and tomorrow

“We need well-defined processes for LabVIEW development and must be precise about what we are doing, while automating as much as possible. Becoming a center of excellence has helped us to reduce the test efforts and impacted our daily work by saving time, being more efficient, and making the software better. I’m proud of the great collaboration.”

Oleg Scherling, HIL LabVIEW Architecture Developer and ZMS motivator to become NI Center of Excellence

“Our team, consisting of radar and HIL experts from ZF and our technology partner ZMS, were able to develop a radar HIL together with NI, which fits perfectly into the existing highly automated ZF validation toolchains to further accelerate our test and development processes.”

Michael Vogt, Engineering Supervisor for ZF’s ADAS Validation Department, responsible for HIL Development in ZF ADAS

“Together with our colleagues from ZMS, we could successfully develop a HIL system that fulfills our requirements using NI components. The HIL system serves as one important pillar in the validation strategy of radar sensors.”

Philipp Strempel, Engineer at ZF’s ADAS Validation Department and Project Lead responsible for radar HIL Development