CATARC Uses Battery-in-the-Loop Simulation to Meet Battery Test Trends

Jian Ding, Engineer in Electronic Control Department, CATARC

Kexin Yin, Engineer in Electronic Control Department, CATARC

Case Study Highlights

- NI’s open, software-connected ecosystem enabled CATARC to develop a scalable battery-in-the-loop (BIL) to meet trends of battery test.

- A BIL system supports abundant test scenarios and boundary conditions. They combine the scene/road/vehicle model, reflecting the real conditions.

“Through the BIL test system, it is possible to accurately control the extreme working conditions such as overcharge, overdischarge, overcurrent, and overtemperature in an environment close to the real vehicle.”

The Challenge

The traditional signal-level HIL test has been well established at the level of BMS functional strategy verification, but the battery pack performance verification capability is seriously insufficient. The road/field test of the real vehicle can obtain the most realistic battery pack performance, but the coverage of the test conditions is too narrow, and the requirements are too high.

The Solution

The battery-in-the-loop (BIL) test solution largely fills the test gap between HIL test and real-vehicle road/site test.

Evolution of Battery Test in the Evolving Chinese Market

As an important strategic direction in China, the development of the automobile industry is in the early stage of commercialization with rapid technological evolution and accelerated industrial layout, and the development of the industry is facing opportunities, risks, and challenges. In this context, pure electric vehicles have great potential to improve economic and industrial competitiveness and attract investment in major developable markets. To avoid the problem of functional safety of automotive software, the automotive industry has developed the vehicle functional safety standard ISO 26262, which is currently the most important international standard in the automotive industry. The standard primarily improves the functional safety of electrical and electronic (E/E) systems by avoiding hazards that can result from malfunctioning behavior of automotive E/E systems.

Complexity of Battery Test in EV Design and Validation

Based on the research of electric vehicles in various countries, there is a common phenomenon: the battery is the most problematic component in the entire realm of electric vehicle research. In the design process to ensure the safety of the battery system, in addition to the characteristics of the battery cell, the design of the battery module, the structure of the battery pack and the exhaust design, the battery management system (BMS) is the most dominant. Many new energy vehicle companies regard the battery management system as the core technology of the enterprise. In recent years, most of the core intellectual property rights applied by a leading OEM are related to batteries, which shows the importance of power battery systems for electric vehicles.

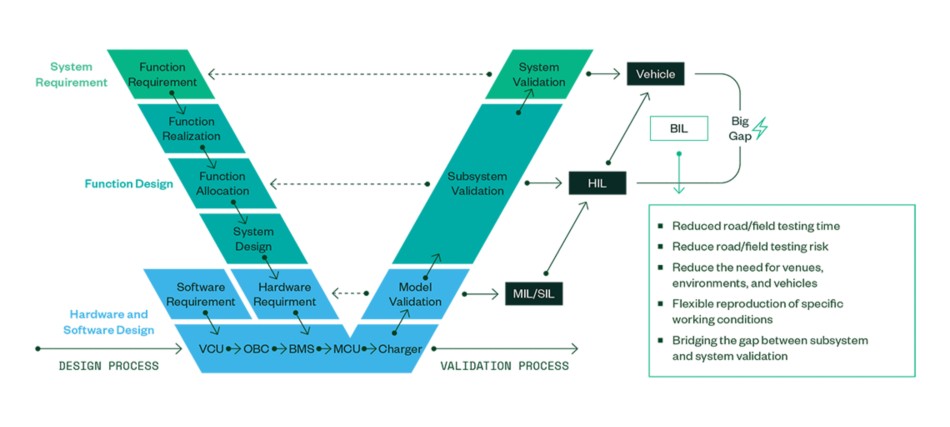

Figure 1: V-cycle Development Flow.

In the development and testing of electric vehicle controllers, the V-cycle development process is generally adopted, as shown in Figure 01, which improves development efficiency, reduces development risks, and reduces workload. The V-cycle development process can complete system requirements, functional requirements, software and hardware design, model verification (MIL/SIL), hardware-in-the-loop testing (HIL), and real vehicle testing, in which HIL testing of the controller plays a key role. The hardware-in-the-loop test platform can be used to establish a virtual controller operating environment, and the functions of the controller can be verified by giving some input signals and detecting output signals.

The traditional signal-level HIL test has been well established at the level of BMS functional strategy verification, but the battery pack performance verification capability is seriously insufficient. The road/field test of the real vehicle can obtain the most realistic battery pack performance. But the coverage of the test conditions is too narrow, and the test conditions are required to be high. And if you want to carry out the real vehicle test in a specific environment, such as high- or low-temperature extreme conditions, the environmental requirements are higher.

CATARC's Battery-in-the-Loop Real-Time Simulation Platform

To improve the authenticity and reliability of the user’s battery pack performance test, CATARC (Tianjin) Automotive Engineering Research Institute Co., Ltd., uses simulation and test to propose a set of battery-in-the-loop (BIL) test solutions. BIL test largely fills the test gap between HIL test and real vehicle road/field test. When compared with real vehicle road/site test, it can minimize the demand for field, environment, and vehicle, which has obvious advantages. The advantages and disadvantages of BIL and real vehicle testing are shown in Table 01.

| Test Methodology | Realism | Scene Richness | Test Flexibility | Test Efficiency | Cost |

| Road Test | High | Low | Low | Low | High |

| BIL Test | Relatively High | High | High | High | Middle |

Table 1: Comparison of Different Test Methods

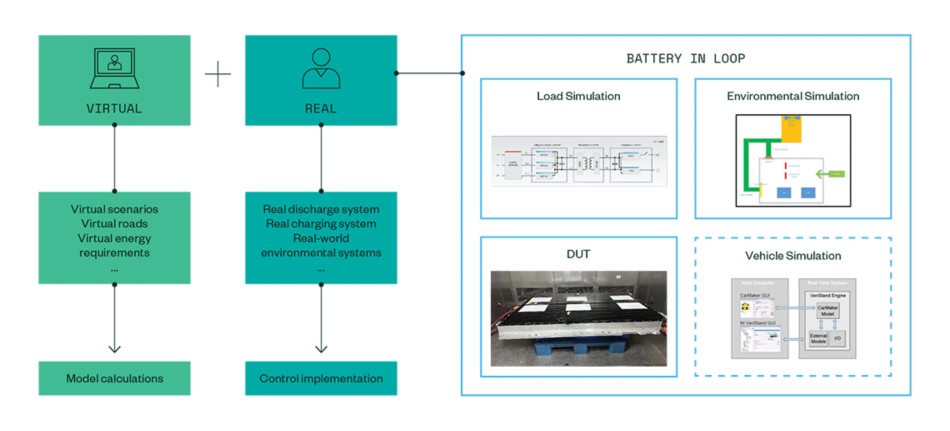

Its system framework includes four main parts: load simulation, environmental simulation, DUT, and vehicle simulation, as shown in Figure 02. Under virtual working conditions, virtual roads, and virtual energy requirements, the system controls the real charging and discharging system. The real environmental system conveniently simulates various real road conditions and obtains experimental data.

Figure 2: Battery-in-the-Loop Test System Framework

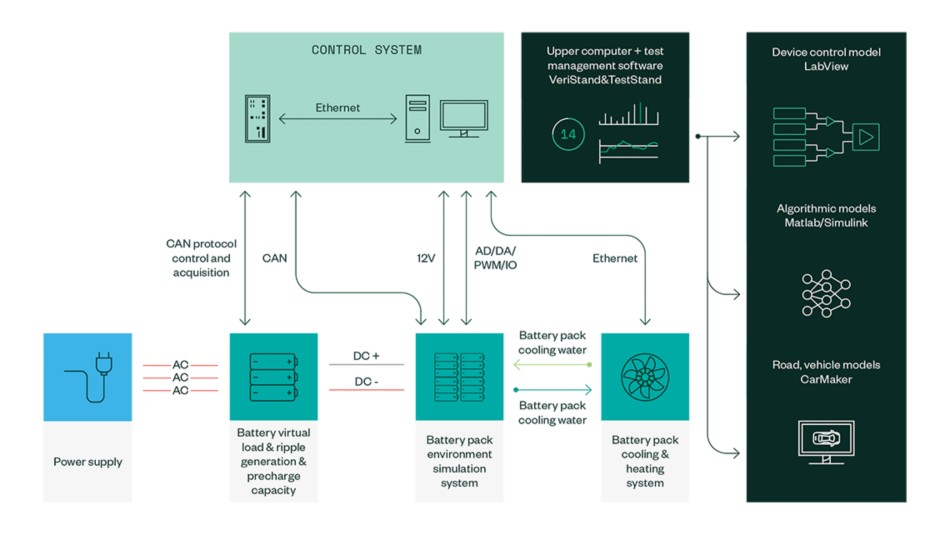

CATARC specifically realizes the battery-in-the-loop test scheme. As shown in Figure 03, the whole system is equipped with environmental chamber, water cooler, virtual load, and other equipment to achieve the real state under the specific working condition test of the battery. Among them, the virtual load of the battery acts as a charging pile and a load to charge and discharge the battery pack. The main control system communicates with the battery virtual load, battery pack environment simulation system, and BMS through the CAN protocol; the BMS realizes the fast-charging function through the CAN protocol. The cooling/heating system of the battery pack mainly realizes the thermal management function of the battery, which is connected to the main control system through Ethernet and is mainly controlled through LabVIEW. Among them, the vehicle dynamics model and road model are built by CarMaker, and other strategy algorithm models are built using MathWorks® MATLAB® software and Simulink® software. The system has the following three advantages:

- It conveniently simulates various real road conditions and extreme working conditions, greatly reducing the demand and time of real vehicle testing.

- It accurately plays back real vehicle data and efficiently finds target performance improvement solutions.

- The interface is open and flexible to adapt to the needs of various models.

Figure 3: Battery-in-the-Loop Test Scheme

In terms of industry cooperation ecology, CATARC has provided battery-in-the-loop testing services for a leading car company. CATARC has provided a large number of test cases and a rich driving scenario library and has also built a complete BIL simulation test platform. The test platform includes software such as Vehicle Dynamics’ CarMaker, automated testing using NI TestStand, and hardware such as HIL cabinets, battery packs, charging and discharging equipment, and water coolers. Through the BIL test system, the realization of test items such as SOX, cycle life, capacity calibration, DCR, pulse charge and discharge characteristics, overcharge/overdischarge rate, thermal management, and so on can be realized. The BIL test platform can customize the test scene, better reproduce the real state of the real vehicle and environment, simulate winter/summer standard working conditions, and complete the real vehicle battery pack charge/discharge performance test requirements.

Taking the discharge condition as an example, the main test steps of the BIL test system are:

- Configure the CarMaker kinetic parameters to be consistent with the real vehicle, build a virtual road, and set the target vehicle speed curve.

- Control the charging and discharging equipment and adjust the battery SOC to the initial value of the test.

- Set the temperature of the ambient chamber and adjust the temperature of the battery cell to the initial value of the test.

- Set the temperature and flow rate of the water cooler and adjust the battery waterway circulation to the initial state of the test.

- Simulate real vehicle interaction for low-voltage/high-voltage power-up.

- Obtain the discharge energy requirement through the CarMaker simulation.

- Control the discharge equipment to absorb the battery and release energy until the end of the test condition.

In addition, through the BIL test system, it is possible to accurately control the extreme working conditions such as overcharge, overdischarge, overcurrent, and overtemperature in an environment close to the real vehicle. The safety objectives are fully verified, and the verification requirements for the functional safety requirements of the battery management system for GB/T 39086-2020 electric vehicles can be realized.

In the future, CATARC will continue to:

- Focus on the research and development of automotive engineering application technology

- Provide automotive enterprises and relevant government departments with automotive performance engineering development, common key technology research, development and verification testing, and related policy and technical consulting services

- Partner with NI to provide higher quality services for intelligent vehicle enterprises and scientific research institutions

- Deploy plans in advance to meet regulatory requirements and laboratory capacity building of high-level autonomous driving functions, leading the key and common technology progress of the automotive industry