Data Logging

By quickly logging and reviewing test data, you can isolate product defects, make timely adjustments, and meet your design and time-to-market requirements.

Scalable, Configuration-Based Data Logging

Logging data is a foundational step in validating any engineering component or system. As systems grow more complex, include a wider variety of measurements, and present more synchronization and environmental challenges, the process of data logging increases in complexity. Nevertheless, you need quick access to data with minimal overhead. Emerson offers a configuration-based data-logging solution suitable for distributed measurements and rugged environments whether you're logging temperature, vibration, pressure, or other physical phenomenon data. With Ethernet-based synchronization and modular connectivity to any sensor, bus, or actuator, NI data-logging hardware and software can scale with your engineering challenges.

Featured Content

Troubleshooting Physical Systems

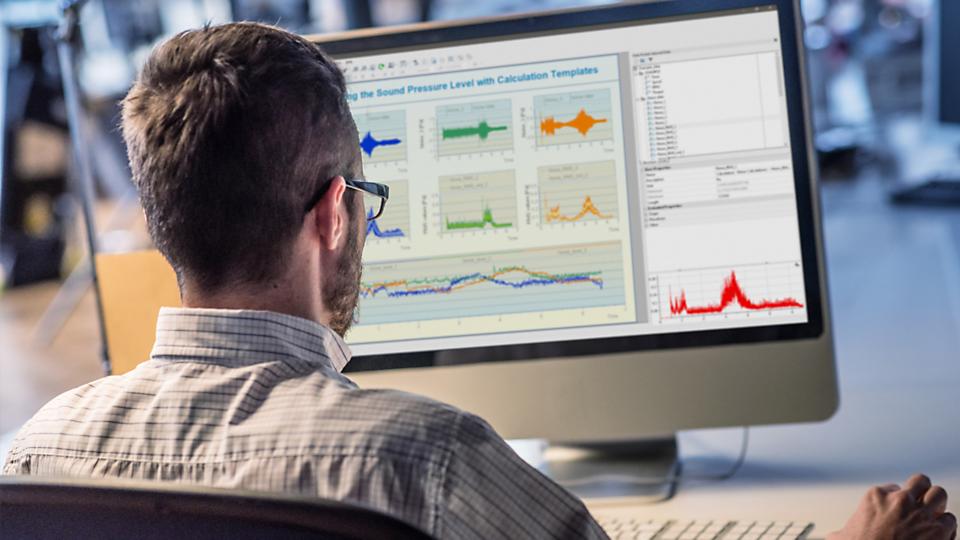

Your ability to troubleshoot depends on your access to data. With NI FlexLogger™ data-logging and data analysis software, you can quickly and interactively review your logged data.

Configuration-Based Data Logging

Configuring and running a data-logging system should be straightforward. Learn how to maximize your investment with one toolchain to test, log, visualize, parse, and report on data from any sensor, bus, or actuator without programming.

Sensor Fundamentals

Temperature, vibration, strain, load, and sound all have specific sensors with specific needs. Learn about common measurement application topics.

Products and Solutions

APPLICATION RESOURCE

Complete Guide to Building a Measurement System

Complete Guide to Building a Measurement System

Before you can log data, you need to set up a reliable measurement system that accounts for signal conditioning and signal processing. Make sure your sensors and data acquisition system are ready for the job.