Under the Hood of Electric Power Measurement and Control Systems

Contents

Overview

It is increasingly difficult to find aspects of our lives that technology has not transformed – from the phones in our hands to how we read books.

Whole industries are converting to the digital domain – the new world of information technology (IT) where software, networks, processors, and sensors fuse and exchange information.

What makes this shift so compelling that seemingly no business can resist? There are many reasons ranging from new features to faster delivery of goods and services to greater productivity. However, first and foremost, is performance over cost. Eventually, information technologies deliver faster rates of improvement because performance increases exponentially (in the numerator) while price decreases exponentially (in the denominator). Businesses that resist “digitization” are at risk of being rendered obsolete.

Look closely at the electrical grid. In contrast to many other industries, the way we generate, transmit, and distribute electrical power is still firmly rooted in “pre-IT” technologies. Despite its millions of miles of humming wires, thousands of power generators, and billions of interconnected devices, the grid still operates primarily under the control of antiquated technologies developed before the modern computer and Internet era. Nonetheless, under the hood of new grid-tied control systems, a digital revolution is under way. The revolution delivers higher performance, lower cost, and essential new features such as seamless integration of electric vehicles, grid-level energy storage, and distributed renewable energy generation. Although in its early stages, the smart grid revolution has begun and no energy business can afford to ignore it.

The Grid Awakens

The first step toward digitizing the grid is distributed sensing technology. Imagine embedded instrumentation systems distributed throughout the grid that acquire electric power signals from transmission lines, digitize them, and transmit them across the Internet. Phasor measurement units, or PMUs, measure the flow by comparing synchronized voltage and phase measurements from multiple points on the grid. The goal is to evaluate grid stability, detect problems before outages occur, and even “heal” the grid when faults happen. This requires real-time analytics to process high-speed data from the grid, feed it into computerized models, and turn it into meaningful results for control room operators. NI refers to this as “acquire, analyze, and present” on a worldwide scale. Satisfying the technical requirements to make this a reality is no simple endeavor. PMUs require accurate measurements of high voltages and currents, precisely synchronized sampling, onboard signal processing, and sufficient communication bandwidth to reliably transmit packets. Driving all of these requirements is the analytics. Measurements stream in at 30 to 60 frames per second from the field. For the algorithms that inform grid operators to work, the data must be up to date and accurate. PMUs based on FPGA technology can help make this a reality by providing high-fidelity measurements and the ability to handle multiple tasks in parallel. Most important is field reconfigurability, which gives the system the capacity to rewire its internal circuitry and adapt to changing requirements. The ability to reconfigure the system down to the silicon gate array level, even after deployment to the field, is critical for the years ahead because the standards for PMUs and other smart grid devices are still evolving. For example, a new PMU standard for precision time synchronization, IEEE 1588 PC37.238, and an updated protocol for communication, IEC 61850-90-5, will not be released until later in 2011.

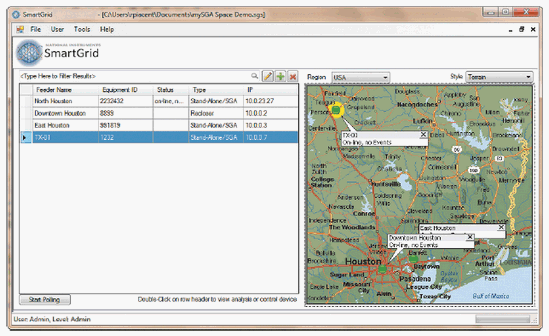

Figure 1: PMUs based on NI CompactRIO provide field-reconfigurable embedded instrumentation – which can be updated remotely even after years of deployment on the grid.

The Grid Responds

The second step toward digitizing the grid is control through intelligent distributed systems that can sense and take action to maintain peak performance. High-performance synchronized measurements, real-time communication, and embedded analytics drive these systems, which increase the reliability of power distribution, the final stage in electricity delivery.

Distribution systems include substations where high-voltage transmission signals are reduced to medium-voltage levels for power lines. Then electricity flows to pole-mounted transformers that provide low-voltage outputs for homes and businesses. The distribution network around the world is undergoing changes to incorporate digital control systems such as smart recloser protection devices.

If your lights have flickered during a thunderstorm, you may have seen a recloser in action. A smart recloser combines electrical switch gear to interrupt fault currents and real-time signal processing to monitor power signals and determine when to open the switch. The devices work like a smart circuit breaker because they protect the circuit in case of fault currents, but they also can “reclose” to restore service and prevent downtime.

The Grid Heals

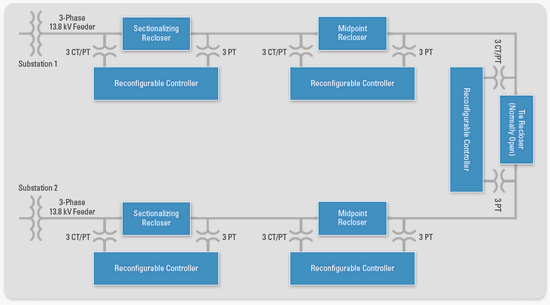

Smart reclosers can increase awareness and reroute power when problems occur. This is known as “self healing.” A loop consisting of two feeders tied together with smart devices achieves a higher level of reliability. Typically there is a sectionalizing recloser near the substation, a midpoint recloser along the power line, and a tie recloser that can optionally connect the two feeds. In the case of a fault, the smart reclosers can provide immediate protection while identifying the nature of the fault. Finally, the system automatically restores and reroutes power to heal itself by activating the appropriate reclosers, minimizing the outage.

Figure 2: A “self healing” power distribution system can automatically sense and adapt to achieve a higher level of reliability.

Think of smart reclosers as the future Internet routers of the smart grid – automatically diagnosing and adapting to the flow of energy. Networked embedded systems that combine instrumentation, analytics, and control are transforming the grid to be more like the Internet – self-diagnosing, self-healing, and distributed rather than centralized. Like the Internet, the smart grid revolution is powered by engineers pioneering the technologies that are modernizing how electricity is produced, consumed, and distributed.