Northrop Grumman Meets Mission-Critical Launch Readiness Deadlines under Pressure

CUSTOMER STORY

AEROSPACE AND DEFENSE | 8 MINUTE READ

NI’s customized solutions are helping Northrop Grumman ensure the mission readiness of critical government programs at Vandenberg Space Force Base.

Up, Up, and Away

The spectacle of rocket launches used to be rare, headline-grabbing events. Today, they occur so often—monthly, weekly, even daily—many of them go uncovered and unnoticed.

Whether for positioning systems, broadband communication and television, meteorology and climate research, cellular connectivity, or Internet access, the demand for launch services is booming across government and commercial sectors. That means more launches, more payloads, and more competition in the launch industry.

Industry stalwart Northrop Grumman is one of the many companies in this market with superior launch capabilities, and it holds multiple standing launchpad contracts in the United States.

Meet the Team at Northrop Grumman

Northrop Grumman is one of the oldest American defense and aerospace technology companies and is an integral part of the country’s space and defense programs. Specifically, Northrop Grumman is the prime contractor for the United States’ Sentinel program, a modernization of the nation’s ground-based strategic deterrent that is critical to national security.

Executing this mission and safeguarding billions of dollars of critical assets and technology is exciting and challenging. But it takes a talented team to stand up to the task. Working at Vandenberg Space Force Base in Santa Barbara, California, Gary Mott is a technical fellow and range certification lead at Northrop Grumman. Mott’s team ensures quality, reliability, and safety in every aspect of the Sentinel’s design and launch.

“It’s a team effort that requires creative thinking and new ideas. Collaboration is needed to keep things running smoothly and improve public safety,” he said.

Northrop Grumman Keynote at NI Connect 2023.

The Launch Vehicle

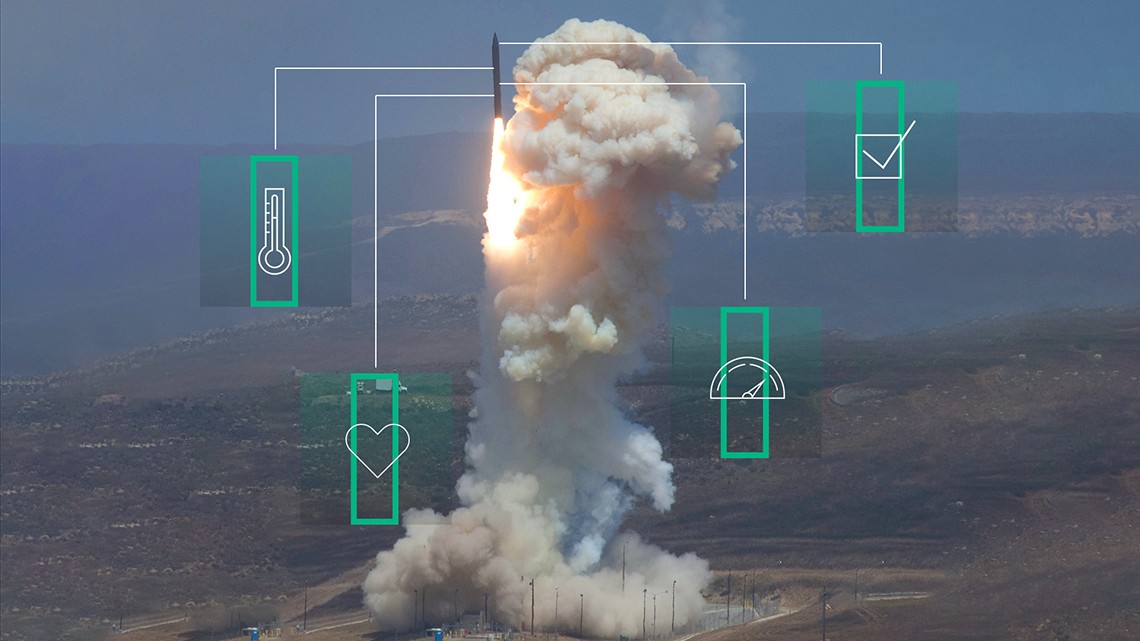

Launch vehicles are more than metal and rocket fuel. They are complex systems with a dizzying number of electronic and electromechanical components that must be tested throughout design and monitored continuously to ensure launch readiness. Distributed control and monitoring systems perform automated routines and collect and send myriad data to the central control system, where operators can make localized control decisions that ensure the success of launch operations.

Monitoring conditions from temperature and pressure to valve states and system status, and every component in between, Mott’s team ensures the launch vehicle is ready at any time.

Add that list of responsibilities to the constant pressure of project deadlines and growing competition, and you’ll get a sense of how closely and intensely Mott’s team must function.

Schedule and Safety Come First

The Northrop Grumman team is used to the tight schedules and high expectations that come with aerospace and defense work. In this situation, one missed deadline could cause a two-year launch readiness delay. But that doesn’t mean projects always run perfectly.

Recently, Mott’s team found itself behind schedule on the Sentinel program launch control and monitoring systems, which monitor the launch environment, protect the rocket’s integrity, and ensure overall performance and safety. Millions, if not billions, of dollars and countless human lives were on the line. Mott’s team couldn’t take any shortcuts. It needed a partner with commercial off-the-shelf (COTS) hardware and flexible software for monitoring and control that could be integrated with its existing sensors and equipment.

“Trust me, you don’t want to be the team that’s holding up a critical government launch,” Mott said.

The team explored several options, from integrating individual components to a complete in-house custom solution, but it couldn’t find a solution that would get the team back on strict program schedules.

Enter NI Solutions

In addition to needing COTS and monitoring software, Mott needed a partner who could quickly process the team’s requirements and had the knowledge and experience to build and deliver a critical design under a compressed timeline.

We had a mission-critical situation, and we were looking for a solution that included trust and rapport to make that difference. NI became the extension of our team.

We had a mission-critical situation, and we were looking for a solution that included trust and rapport to make that difference. NI became the extension of our team.

Thankfully, NI has decades of serving as a trusted aerospace, defense, and government advisor with a deep understanding of how to optimize strategies to meet increasingly demanding technical requirements. It was a perfect match.

NI partnered with Northrop Grumman from problem statement to solution, defining the requirements, designing the system, building it, and delivering the hardware and software in fully integrated racks with instrumentation. NI also provided documentation, including mechanical drawings, setup instructions, and spec sheets, to decrease the burden on Mott’s team and maximize the usability of the delivered systems.

“It’s an immediate shot in the arm compared to developing that system internally,” Mott claimed. Thanks to the NI Solutions Group, the Northrop Grumman Vandenberg team was able to standardize on a COTS approach for monitoring and control, as well as reuse that standardization across multiple launch locations.”

The NI and Northrop teams communicated weekly and even daily about milestones and deliveries. “We had a mission-critical situation, and we were looking for a solution that included trust and rapport to make that difference,” Mott said. “NI became the extension of our team.”

NI’s plan produced the systems faster than Mott thought possible and brought the team back on track in terms of program schedules. Most importantly, the NI solution involved a phased approach, where preliminary systems were delivered to the Northrop team early, so they could begin software development ahead of schedule and iterate on software design and functionality while final integrated systems were in development, putting the team even further ahead of program schedules.

This partnership was built on a foundation of teamwork and creativity, allowing Mott’s team to meet technical requirements while adhering to strict program schedules without sacrificing quality, safety, or reliability. Mott said getting back on track was only possible with the integrated plan NI developed with his team. “It was exactly the kind of alliance we were looking for when we set out to solve our schedule and scalability challenges,” Mott said. “The NI Solutions team came up with innovative ideas to help us focus on our requirements and what was driving us, and they provided invaluable answers.”

NI’s Interview with Gary Mott at NI Connect 2023.

The appearance of U.S. Department of Defense (DoD) visual information does not imply or constitute DoD endorsement.