System on Demand Agile System Development Process

Overview

System on Demand (SoD) is an agile system development process that takes advantage of modular and standard components to design, integrate, and deliver validation and functional test systems for LRU hardware, embedded software algorithms, hardware in the loop (HIL or HWIL), integration labs, and more. Where others still operate on a linear integration model, SoD provides multiple parallel tasks that start with components of the test solution that are unlikely to change as the program matures. Tasks surrounding components that need more flexibility to change as the test requirements are finalized then happen at the end of integration. This automated procedure results in delivery of a testing platform on a shortened timeline.

The SoD development process was created by SET GmbH and Tech180, now part of NI Test & Measurement at Emerson.

You’ll always have to test, but you don’t have to test the way you always have. NI’s modular, reconfigurable platforms let you solve the world’s toughest challenges faster.

Contents

The Problem

Aerospace is changing. Space travel and flying cars are closer than ever. The flight-certified products of tomorrow will require more features and more complex software and controls, which you’ll need to test and deliver in shorter timeframes.

In a perfect world, your test equipment timeline is front-loaded to align with the speed of innovation. You would start with stable requirements, add in the longer lead customizations, and then tackle test, fixes, and integration rework.

In the real world, labor and risk get pushed later in the project. Delays in receiving input and rework from requirements churn lead to last-minute crunches. Costs go up as your deadline looms. Rework during integration drags on.

While it seems like you could solve the challenges by starting earlier, the heart of the problem is controlling risk. Committing yourself to the entire system design upfront leaves you vulnerable when requirements inevitably change throughout the program. Your initial decisions can make or break the project, as the cost and time to make changes later add up fast. You can’t separate decisions about the less risky parts of the test system from the riskier parts, and getting it wrong means delays and budget overruns. The pressure to get it right, without changes later, is immense—and unrealistic.

What if you could have portions of the system done and validated before you ever have to make a decision about the riskier parts? What if the coverage you need is ready before you need it?

What you really need is test coverage of your program. See how NI delivers test coverage throughout the program, not just a test rack near the end of the program.

The Solution

SoD is the first-ever Agile system development process, allowing us to specify, design, build, and validate individual portions of a test system unit by unit. Instead of a lengthy waterfall process, you get a cutting-edge system that lowers your risk. Even better, it’s ready in weeks instead of months—without breaking your budget.

From hardware and software configuration services to complete standardization solutions, NI can help you accelerate your test program and stay ahead of your competition.

NI test systems are built to meet the requirements of your testing. By using standardized system designs and modular COTS hardware, NI can significantly reduce your system design and integration effort.

Agile System Development

It’s a familiar scenario: a clunky, time-consuming process means you need to wait for your entire test system design to be completed before you can start building it. As a result, the system isn’t ready in time, delaying the project, blowing the budget, and sending stress levels through the roof.

Here’s where our Agile development process really shines. You don’t always have all the product requirements you need to build a tester by the time the schedule dictates that you must begin. We can get started with the information that you do have; our architecture allows us to make many types of changes later—without significant cost or impact on the production schedule.

NI uses a unique Agile development process to complete entire portions of your test system even as other requirements are being finalized. We divide design into stable requirements and changing requirements, allowing us to start building sooner while still leaving the space and interfaces to incorporate longer lead items.

Without the delays of a serialized waterfall process, we can build and unit test even down to individual requirements. Segmenting the system in this way provides greater adaptability and reduces risk while helping you keep your project on schedule. The inflexible design process is a thing of the past.

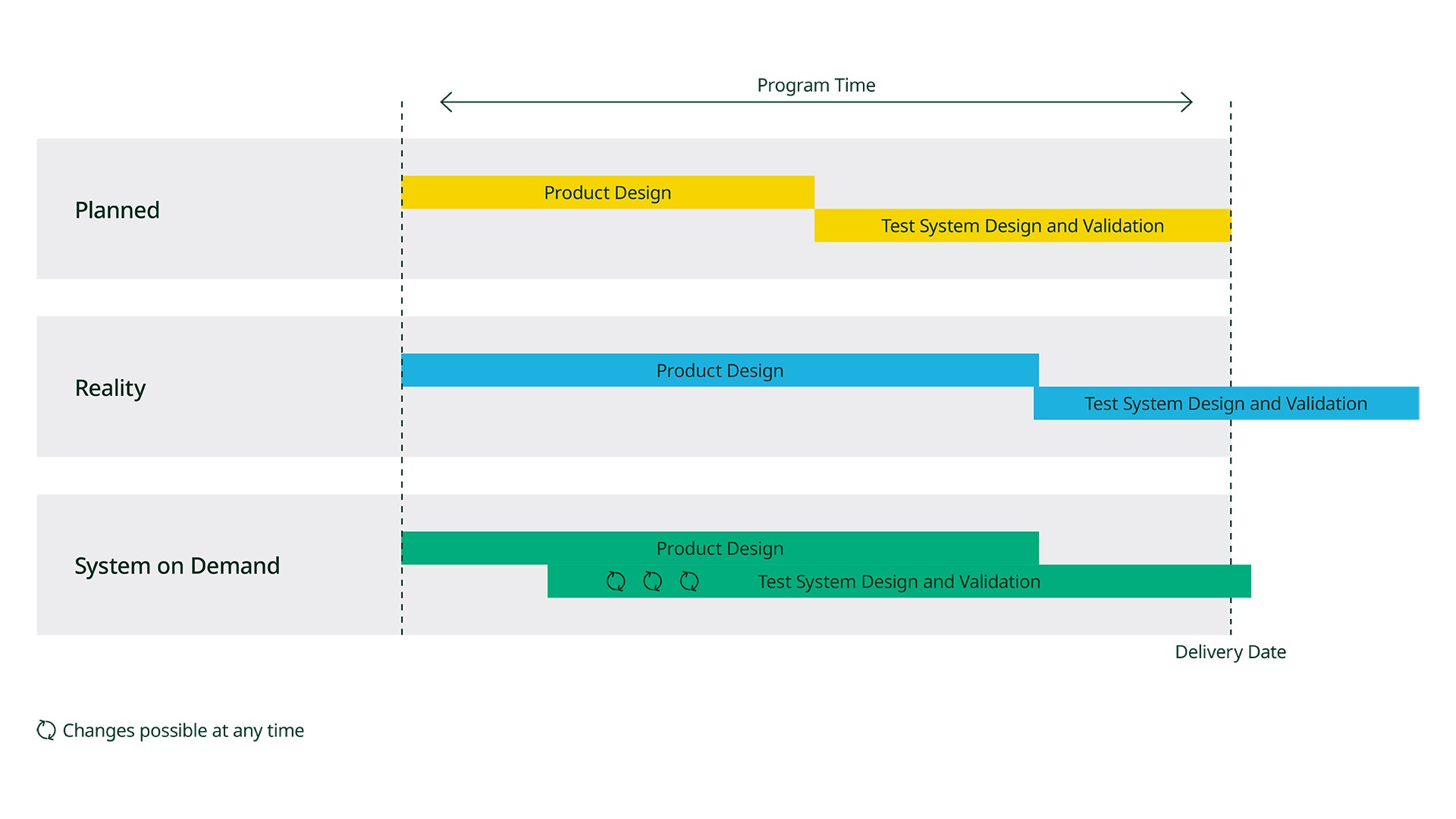

Figure 1: Embrace a test system development process that avoids the inevitable schedule delays of designing and validating test solutions at the end of the program.

Modular and Standardized Hardware Implementations

SoD test systems are composed of COTS hardware components that include standard signal connectivity, cabling, and rack infrastructure as well as modular signal conditioning and instrumentation. Therefore, most signal types have preconfigured, off-the-shelf designs that are already validated for compatibility and function. Each signal type also comes with significant documentation as well.

Our modular architecture and Agile process avoid costly point-to-point wiring and custom design. We can start building and verifying functionality from day one, allowing for system delivery in weeks rather than months.

NI uses a standard approach for signal classification to build your aerospace test system.

Additionally, NI test engineers can enhance these system designs with different fault conditions for verification and validation purposes. User-defined routings support the switch between real hardware and simulated devices. In this way, you can cover various test scenarios and start testing in early project phases without having all the components available.

See how our black-box approach enables us to develop your system while waiting for any long-lead requirements to mature.

All standard aviation interfaces are available.

As part of our architecture, we have predeveloped and standardized 80 of the most common signal types. By using these prevalidated signals, we can reduce development and testing risk from your projects.

Easy debugging.

Our systems have the option for built-in or external self-test, so you can quickly verify the source of any errors. Additionally, our cabled connections make it easier to maintain and modify the system. NI always provides complete drawings, a bill of materials, and signal trace documentation.

Fitting into Your Existing Software and Modeling Workflow

The SoD procedure is completed in a system with an open architecture. The testing software inside the LRU system is adjusted to the stage of the lifecycle to be checked while the hardware remains mostly unchanged.

SoD also takes advantage of abstraction layers to communicate between the test engineering software stack and the hardware. That way any changes made to the test sequence or user interface can happen without affecting the communication interfaces to the test hardware.

The communication interfaces to test hardware, core system operation, and utility software are all based on off-the-shelf software tools from an industry-standard test programming language to multiple pieces of supported application software

LabVIEW, LabVIEW FPGA, and LabVIEW Real Time

LabVIEW is a graphical programming environment test engineers use to communicate with instrumentation and collect data in LRU validation, HIL, and production test systems. As part of the SoD process, we translate your specific requirements into structured and transparent LabVIEW applications. The LabVIEW FPGA and LabVIEW Real-Time Modules enable the generation of real-time applications and FPGA code from within LabVIEW. LabVIEW training is one of the many services that is offered as part of the SoD process.

TestStand

TestStand is powerful software to structure test sequences and represent them using a simple configuration. Our experienced and certified TestStand developers (CTD) and architects (CTA) assist you quickly and efficiently to obtain a high-performance test solution, operator interfaces, and custom step type libraries.

VeriStand

VeriStand is software used to configure data acquisition and logging, sequence real-time test sequencing, and integrate simulation models during the fast commissioning of your control, regulation, and monitoring system.

Third-Party Software Integration

No matter the tools you have chosen to build your current software workflow, SoD is tailored to your needs. If you want to test in Python, you can test in Python. Our real-time software is specially designed to work with MathWorks® Simulink® software as a modeling environment. If you want to run your models on your own server instead of in our PXI controller, we can support that. We work hard to ensure that changes in hardware have as little impact as possible on your preferred workflow.

MathWorks MATLAB® Software and Simulink Software

Simulation models of any kind are a big part of many embedded software test and HIL real-time test systems in aerospace. VeriStand natively supports the integration of MathWorks MATLAB software and Simulink software models into this real-time environment. We are happy to assist you with the integration. If the models turn out to be a bit larger, we can show you our software architecture (Reflective Memory Network with dedicated simulation computers) for particularly computationally intensive models and their integration into the VeriStand real-time environment.

Python

Do you use Python as a standard development environment for test automation and already have validated and certified test sequences? Do you want to modernize your test environment but are afraid of the effort of adapting existing software modules?

NI can help you integrate your existing software applications and show you the many ways in which you can easily and conveniently integrate the NI toolchain into your existing Python test environment.

The Benefits of Working With NI

When outsourcing your test system creation, you need a partner that speaks your language and delivers the system requirements and coverage you need. NI’s open-source, modular architecture helps you and your vendor to deliver the same requirements to the pin of the product. NI can deliver solutions in multiple formats, from a bill of materials to a turnkey system and everything in between.

You won’t typically need to provide a statement of work for every requirement. Instead, tell us what interfaces your product has, and we’ll generate the solutions to meet the requirements of each interface. In most cases, we already have a solution for about 80 percent of a test system, letting us focus on the riskier parts of the system.

Reuse and Extension with SoD

With SoD, you do not need a separate test system for every new UUT. Instead, previous designs can be reused and extended. Based on your new requirements, we can analyze the interfaces that need extension, define the necessary system add-ons, and configure the system accordingly. Then, you can decide what’s next: We will make the manual and the documentation available to you so that you can proceed with the installation—or we will cover necessary adjustments according to your requests.

With SoD, the lead time necessary to make a test system available to you is as short as 12 to 15 weeks. Additionally, the entire design documentation and specifications are available shortly after the project kickoff. And you will receive the complete simulation environment directly after we have finished the design.

The entire configuration is completed in the quotation phase; consequently, you will get a complete picture of your system, along with its capabilities and features right from the start. This documentation ensures a precise delivery date, which you will also find as part of your quote.

The Key to Digital Sovereignty

With SoD, you get an open system including the entire documentation and design data that enables you to completely understand your test system so that you can autonomously adjust to the rapid changes in market requirements. Therefore, you can operate independently of any third party for a long period of time. At the same time, NI can help you reduce laborious development activities. With SoD, you get a complete overview on all the signals inside the hardware and software, ensuring that the entire expertise on the test system remains within your company.