NI and EN4 Revolutionize Lilium's eVTOL Test

Case Study Highlights

- NI and EN4, an NI partner, collaborated to help Lilium develop a modular and extendable testing environment for their eVTOL aircraft.

- Lilium’s Electrical Power System Lab significantly enhanced the safety and reliability of their eVTOL jets through rigorous validation tests.

- The advanced testing capabilities of the lab facilitated Lilium’s compliance with evolving aviation regulations, accelerating their market readiness.

“By relying on NI technology, we were able to provide a comprehensive solution for Lilium’s Electrical Power System Lab, ensuring extremely high accuracy in the measurements provided, while also maintaining operational flexibility essential for a cutting-edge and dynamic sector like electric aerial mobility.”

- Luigi Foschini, EN4 Technical Director

The Challenge:

Lilium aimed to build a cutting-edge Electrical Power System Laboratory (EPSL) for their eVTOL aircraft, facing challenges like evolving EASA and FAA standards, high battery voltage up to 1200 VDC, and the need for robust safety tests. The lab required quick development to meet market deadlines and had to integrate fluidic, mechanical, and electrical testing into one system, demanding advanced equipment and strict quality control.

The Solution:

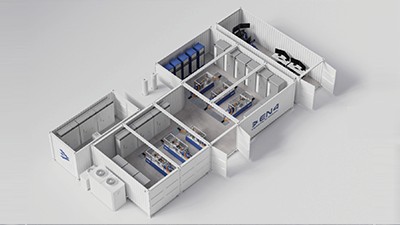

NI and EN4, an NI partner, combined their expertise to develop Lilium’s eVTOL-dedicated EPSL facility, blending EN4’s system integration with NI’s test and measurement technologies. The result was a modular, extendable testing environment, enabling immediate development and future-proofing for evolving requirements. Risk mitigation and seamless integration between EN4, NI, and Lilium were key to the project’s success.

The Role of a Cutting-Edge Electrical Power System Lab

Lilium’s mission to revolutionize regional air mobility with their electric vertical takeoff and landing (eVTOL) jets is being greatly accelerated by their cutting-edge Electrical Power System Laboratory. The test facility allows Lilium to install key aircraft components in a way that is representative of the aircraft’s operation. This configuration produces an integrated testing environment in which components that work well separately are evaluated collectively, revealing how they perform together under different scenarios. Engineers recreate flying scenarios using custom software from a control room, spotting any potential flaws in real time to guarantee each system works properly prior to the aircraft’s first manned flight.

The lab’s ability to conduct extensive integration testing is crucial for reducing risk potential in-flight issues. Several phases are defined to anticipate and carry out various tests. For instance, these phases include a preliminary version of the units under test (UUTs) with a partial lab setup using dynamometers and battery simulators—then later a flight version of the UUTs with a complete, fully equipped test lab including real battery packs. The lab guarantees that these parts work harmoniously by verifying the seamless operation of individual components. This controlled environment allows Lilium to identify and handle shortcomings that might only manifest during real flight scenarios, enhancing reliability as well as safety. Depending on the status of the test, some are required for the first manned flight, while subsequent tests are necessary for certification.

Furthermore, the lab enables abuse tests that are impractical or unsafe to execute during a real flight, such as short circuit and open circuit failure injection. These tests are essential for demonstrating that the eVTOL is robust enough to failure situations and making sure the aircraft is capable of withstanding and safely handling unexpected scenarios. Such rigorous testing is critical to meeting the high safety standards stipulated for aviation.

As aviation regulations continue to evolve, the lab's comprehensive testing capabilities are fundamental for certification. The lab assists Lilium in meeting strict regulatory criteria by testing and simulating various scenarios, which paves the path for their aircraft to obtain the required certifications. Even after the aircraft is certified and enters service, the lab will continue to support ongoing research and development to ensure safety and enhances functionality, serving as a digital and electrical twin for the aircraft across its entire lifecycle.

The EN4 and NI Solution

With NI’s cutting-edge hardware and software, seamlessly integrated by EN4, Lilium has a complete test solution. This solution comprises power converters for dynamometer control, ERS-BIC 1 MW, all controlled by NI PXI hardware. NI's PXI systems facilitate data acquisition, test cell automation, and HIL, while NI LabVIEW for Windows, LabVIEW Real-Time, and LabVIEW FPGA enable software development. NI EtherCAT driver secures effective communication, and NI DIAdem handles data management and analysis.

Using NI’s architecture to provide Lilium with a turnkey solution, this unique system integrates modeling, communication bus, acquisition, control, power electronics, and post-processing in DIAdem. The ERS-BIC battery simulator is used to control the high power and voltage levels. Using NI services, a vital resource for Lilium, guaranteed calibration traceability. Additionally, the use of the same platform in LabVIEW facilitates software development collaboration, allowing parts developed by EN4 and Lilium to work together seamlessly. This integration of EN4’s expertise with NI’s advanced hardware and software products, combined with Lilium’s key contributions to the design and development of the solution, has provided a solid foundation for rigorous testing and development, thereby ensuring safety, reliability, and regulatory compliance.

The Advantage of the EN4 and NI Partnership

The partnership between EN4 and NI offered Lilium an efficient and flexible testing environment tailored for their eVTOL systems. NI’s hardware and software solutions, along with EN4’s experience in system design and integration, allowed for accurate control, data collection, and analysis throughout the testing process. Often, it is necessary for the customer to test the same device on different benches, emphasizing the significance of code openness to use software parts in different systems, ultimately saving time and resources.

This comprehensive solution accelerates development by enabling iterative testing, early issue identification, and rectification, thereby reducing time and costs. Additionally, the EN4 and NI solution has made it possible to model some components effectively and efficiently, which is crucial for maximizing functionality and performance. Top-range precision and reliability were guaranteed in the measurement performance, which is essential for certification in such a critical sector.

Furthermore, EN4’s broad experience in the automotive industry helped to overcome the particular issues faced by the eVTOL sector, which are similar to those faced by automotive testing. This expertise was essential for navigating the unique demands of eVTOL development. The EN4 and NI solution demonstrated dynamism and adaptability, quickly adjusting to the shifting testing requirements that are characteristic of a cutting-edge technology industry. This adaptability further streamlined the certification process, ensuring compliance with strict aviation standards while accelerating Lilium’s journey towards market readiness.

Future Plans

NI, along with EN4’s expertise, is committed to supporting Lilium throughout the eVTOL'’s journey to market readiness and commercial launch. Our collaboration extends beyond the lab to ensure the success of Lilium’s revolutionary eVTOL aircraft. By leveraging our expertise in manufacturing optimization, system integration, testing, quality control, and regulatory compliance, we continue to work closely with Lilium to streamline their processes and establish robust supply chains, efficiently meeting market demand for their revolutionary eVTOL aircraft.

An NI Partner is a business entity independent from NI and has no agency or joint-venture relationship and does not form part of any business associations with NI.