Developing Smart Tools for the Airbus Factory of the Future

Sébastien Boria, Airbus

"We evaluated several systems on modules (SOMs) and embedded single-board computers (SBCs), and there is no comparison to the software integration offered by NI. We estimate that our time to deliver with the NI SOM is a tenth of the time using alternative approaches because of the productivity gains of NI’s approach to system design, particularly with NI Linux Real-Time and the LabVIEW FPGA Module."

- Sébastien Boria, Airbus

The Challenge:

Manufacturing and assembly of aircraft, which involves tens of thousands of steps that must be followed by the operators, and a single mistake in the process could cost hundreds of thousands of dollars to fix, makes the room for error very small.

The Solution:

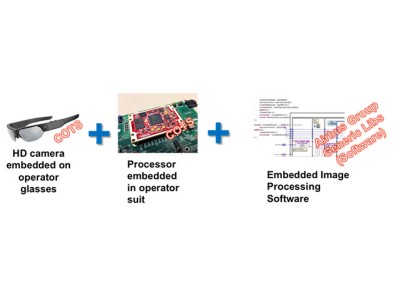

Adding intelligence to the tools and shopfloor systems to help simplify the production process and improve production efficiency by managing and checking the tasks the operator is completing. Using the NI System on Module, we can quickly prototype these smart tools.

Today’s aerospace factory floor is nothing like the hectic, noisy production facility of the past. The latest techniques, designs, and equipment make modern manufacturing efficient, organized, and structured. And what about tomorrow? The future of the aircraft factory is a research and technology project aimed to push emerging technologies to improve the competitiveness of Airbus manufacturing processes where manual operations are still predominant today.

Cyber-physical systems and Big Analog Data™ enable a smarter, operator-centric production that allows operators and machines to collaborate in the same physical environment. The Factory of the Future also implies the extensive use of a modular platform with a high level of abstraction based on commercial off-the-shelf modules. One of the key components for improving efficiency in the Factory of the Future is smarter tools. These smart devices are designed to communicate with a main infrastructure or locally with operators or other tools but only when it is required provide situational awareness and make real-time decisions based on local and distributed intelligence in the network.

In the case of a manufacturing facility, smart tools can help simplify the production process and improve efficiency by removing physical data logs and manuals. Operators must focus on their operational tasks, during which they need to keep their hands free for using the appropriate tools. Most of the previous initiatives linked to “paperless projects” were focused on “paper suppression,” or replacing paper with tablets, but they still consumed “passive/dead data.” Smart tools enable another alternative, “data in context,” which is generated and consumed continuously—in other words, “live data.”

Developing an airplane involves tens of thousands of steps that operators must follow with many checks in place to ensure quality. By adding intelligence to the system, the smart tools understand the actions that the operator must perform next and automatically adjust the tools to the proper settings, which simplifies the task for the operator. Once the action is completed, the smart tools can also monitor and log the results of the action, which improves the efficiency of the production process.

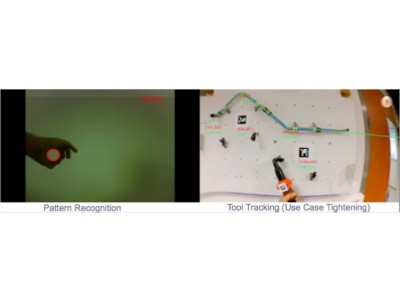

As an example, a given subassembly of an airplane has roughly 400,000 points that need to be tightened down, which requires over 1,100 basic tightening tools in the current production process. The operator has to closely follow a list of steps and ensure the proper torque law settings for each location using the correct tool. Because of the manual process, human error adds a lot of risk to the production. This is significant since even a single location being tightened down incorrectly could cost hundreds of thousands of dollars in the long run. A smart tightening tool understands which task the operator is about to perform using vision to process its surroundings and automatically set the torque. And the device can record the outcome of the task in a central database to ensure the location was set properly. With the central manufacturing execution system (MES) database and the distributed intelligence of the devices, production managers can precisely pinpoint the procedures and processes that need to be reviewed during quality control and certification.

Airbus is launching the development of three smart tool families that perform different manufacturing processes: drilling, measuring, and quality data logging and tightening.

Drilling Tool

- Process surroundings with vision algorithms

- Verify which material is about to be cut through

- Update cutting conditions of the drill at each material layer

- Monitor the drilling depth

- Log the results of the drill at the current location

- Monitor system health

- Perform automatic checks/calibration

Measuring Tool

- Process surroundings with vision algorithms

- Retrieve acceptable measurement values from a database

- Check that the measurement is within the parameters

- Log results and provide follow-up actions if necessary

- Perform automatic checks/calibration

Quality Validation Tool (Based on Human Decision)

- Process surroundings with vision algorithms

- Perform human native interaction (finger tracking, eye tracking, voice control)

- Log results and provide follow-up actions if necessary

Tightening Tool

- Process surroundings with vision algorithms

- Set the appropriate torque/speed/angle laws for the location

- Monitor the torque applied to the fasteners

- Log the given torque to a central MES database or an enterprise resource planning system

- Perform automatic checks/calibration

We tested the NI SOM as the foundation platform for all of these smart tools because of the ubiquitous architecture and framework that it provides to accelerate the development process from design to prototyping to deployment. Before developing on the NI SOM, we were able to create a prototype based on an NI CompactRIO controller (cRIO-9068) that allowed us to integrate IP from existing Airbus libraries and open-source algorithms to validate our concepts quickly. The flexibility of using graphical and textual programming along with reusing third-party development ported on top of the Xilinx Zynq and the NI Linux Real-Time OS offers the perfect level of abstraction for developing these tools. We can now reuse the code that we have developed on the NI SOM as a deployed solution rather than having to restart our entire design process.

We evaluated several SOMs and embedded single-board computers (SBCs), and there is no comparison to the platform-based design approach and the hardware-software integration offered by NI. We estimate that our time to deliver with the NI SOM is a tenth of the time using alternative approaches because of the productivity gains of NI’s approach to system design, particularly with NI Linux Real-Time and the LabVIEW FPGA Module. With the software already provided by the NI SOM, we can focus more on the key features of our system such as image processing on FPGAs.

Factory of the Future at Airbus is an incremental long-term research and technology project that is critical to our competitiveness in manufacturing processes. Rapid development is critical for our incremental approach of new technology, from initial proof of concept development to real object dissemination. We have carefully planned this initiative over the past few years, and, with NI technology, we can accelerate our development process and bring our vision into reality.

Author Information:

Sébastien Boria

Airbus