Virtual Instrumentation for Test, Control, and Design

Overview

Virtual instrumentation has been widely adopted in test and measurement areas. It has gradually increased addressable applications through continuous LabVIEW innovation and hundreds of measurement hardware devices. Today, National Instruments is leading the charge to expand this technology to the control and design sectors. The benefits that have accelerated test development are beginning to accelerate control and design. Engineers and scientists who are increasing demands for virtual instrumentation in hopes of efficiently addressing worldwide demand are the driving force behind this acceleration.

Contents

- Virtual Instrumentation for Test

- Virtual Instrumentation for Industrial I/O and Control

- Virtual Instrumentation for Design

- Next Steps

Virtual Instrumentation for Test

Test has been a long-proven field for virtual instrumentation. More than 25,000 companies (the majority being test and measurement companies) use National Instruments virtual instrumentation. Now, companies quickly are adopting up to 200 MS/s digitization capabilities. The PXI consortium hosts more than 60 members delivering hundreds of products. And tens of thousands of R&D, validation, and product test engineers and scientists literally use thousands and thousands of instrument drivers.

Still, the need for test has never been greater. As the pace of innovation has increased, so too has the pressure to get new, differentiated products to market quickly. Consumer expectations continue to increase; in electronics markets, for example, disparate function integration is required in a small space and at a low cost. The economic downturn of recent years has not curbed the need to innovate, but instead has added the restraint of fewer resources. Meeting these demands is a factor in business success – the company that can meet these demands quickly, consistently, and most reliably has a decided advantage over the competition.

All of these conditions drive new validation, verification, and manufacturing test needs. A test platform that can keep pace with this innovation is not optional, it is essential. The platform must include rapid test development tools adaptable enough to be used throughout the product development flow. The need to get products to market quickly and manufacture them efficiently requires high-throughput test. To test the complex multifunction products that consumers demand requires precise, synchronized measurement capabilities. And as companies incorporate innovations to differentiate their products, test systems must quickly adapt to test the new features.

Virtual instrumentation is an innovative solution to these challenges. It combines rapid development software and modular, flexible hardware to create user-defined test systems. Virtual instrumentation delivers:

- Intuitive software tools for rapid test development;

- Fast, precise modular I/O based on innovative commercial technologies

- A PC-based platform with integrated synchronization for high accuracy and throughput

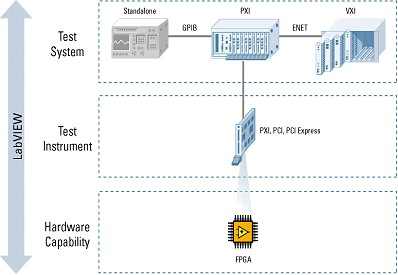

An example of recent National Instruments innovation accelerating test, control and design is FPGA-based hardware programmed using LabVIEW FPGA. If an engineer needs a new hardware capability, like onboard DSP, or a new triggering mode, you can drill down even further to define this capability in the same software and deploy it to an on-board FPGA. Engineers and scientists have always been able to use LabVIEW to create highly integrated user-defined systems using modular I/O but they can now extend custom configurability to the hardware itself. This degree of user-configurability and transparency will change the way engineers build test systems.

Figure 1: LabVIEW offers user-defined instruments and customizable hardware

Virtual Instrumentation for Industrial I/O and Control

PCs and PLCs both play an important role in control and industrial applications. PCs bring greater software flexibility and capability, while PLCs deliver outstanding ruggedness and reliability. But as control needs become more complex, there is a recognized need to accelerate the capabilities while retaining the ruggedness and reliabilities.

Independent industry experts have recognized the need for tools that can meet the increasing need for more complex, dynamic, adaptive, and algorithm-based control. The PAC is the industry’s request and virtual instrumentation’s answer.

An independent research firm defined programmable automation controllers (PACs) to address the problem. Craig Resnick of ARC Research defines PAC as:

- Multidomain functionality (logic, motion, drives, and process) – the concept supports multiple I/O types. Logic, motion, and other function integration is a requirement for increasingly complex control approaches

- A single multidiscipline development platform – a singular development environment must be capable of supporting varying I/O and control schemes

- Software tools for designing applications across several machines or process units – the software tools must scale to distributed operation

- A group of de facto network and language standards – the technology has to take advantage of common and often high-investment technologies

- Open, modular architectures – the design and technology specifications must be open, modular, and combinable in implementation

PACs deliver PC software flexibility with PLC ruggedness and reliability. LabVIEW software and rugged, real-time, control hardware platforms are ideal for creating a PAC.

Virtual Instrumentation for Design

The same design engineers that use a wide variety of software design tools must use hardware to test prototypes. Commonly, there is no good interface between the design phase and testing/validation phase, which means that the design usually must go through a completion phase and enter a testing/validation phase. Issues discovered in the testing phase require a design-phase reiteration.