LabWindows™/CVI™ State-of-the-Art Hardware Connectivity

Overview

Often the most critical process in a measurement application is connecting to an instrument and taking measurements. NI LabWindows™/CVI simplifies the task of connecting to and communicating with a wide variety of instruments. With the LabWindows/CVI built-in measurement libraries, you can quickly acquire data from GPIB, USB, serial, Ethernet, PXI, and VXI instruments the built-in instrument I/O libraries or using built-in instrument drivers. In addition, LabWindows/CVI streamlines data acquisition and instrument connectivity capabilities with interactive measurement tools. It provides two measurement assistants, which simplify the acquisition process.

Contents

- Connect to Any Hardware With Built-in Hardware Libraries

- NI Hardware

- Third-Party Hardware

- Get Started Faster With the Data Acquisition Assistant

- Easily Test Physical Connections

- Save Time With the Instrument I/O Assistant

- Generate Instrument Drivers With the LabWindows/CVI IVI Instrument Driver Wizard

- Communicate With User-Programmable FPGA Hardware

- Additional Resources

Connect to Any Hardware With Built-in Hardware Libraries

Because LabWindows/CVI is a programming environment designed for developing measurement applications, it includes a large set of run-time libraries for instrument control and data acquisition.

Data Acquisition Libraries: Use the data acquisition libraries with data acquisition and switch devices to develop solid instrumentation, acquisition, and control applications.

Modular Instrument Libraries: Take advantage of built-in instrument driver APIs to communicate with the latest PXI instrumentation such as radio frequency (RF), high-speed digital I/O (HSDIO), digital multimeters (DMMs), controller area network (CAN), XNET, and more.

Instrument Control Libraries: LabWindows/CVI is an optimal tool for controlling and connecting to instrumentation. The built-in GPIB, Virtual Instrument Software Architecture (VISA), RS232, and TCP libraries ensure seamless connectivity to any instrument bus.

NI Hardware

National Instruments is a global market leader in PC-based data acquisition with a complete family of data acquisition products for desktop, portable, industrial, and embedded applications. You can use the built-in NI-DAQmx driver libraries to integrate more than 200 data acquisition devices in LabWindows/CVI on a variety of major buses and form factors, including USB, PCI, PCI Express, PXI, PXI Express, wireless, and Ethernet.

In addition to data acquisition hardware, NI also offers other specialty test, measurement, and control hardware. Modular instruments are used for synchronizing measurements, signal generation, RF, and switching components for automated test systems. Vision devices also offer unique capabilities, such as verifying component positioning, counting physical elements, and reading bar codes, which are not found in many traditional sensors. Each hardware type includes its own driver software for easy integration into LabWindows/CVI. Examples include the following:

|

|

The drivers for all of these products were designed with LabWindows/CVI in mind and feature convenient access to all of the available functionality of the hardware. The driver installs directly into LabWindows/CVI and adds new functions to the Library Tree so that you waste no time locating and including support for your hardware.

NI device drivers generally implement advanced features such as device name aliases and hardware simulation so you can develop software without tying yourself to a particular device. As long as your device supports the same functionality, the driver can adapt to the new device, even if the underlying technology changed dramatically, such as when moving from a PCI-based data acquisition device to a wireless device.

You can also create real-time systems on NI hardware using LabWindows/CVI.

Third-Party Hardware

LabWindows/CVI does more than just connect to NI hardware. LabWindows/CVI also connects to thousands of third-party instruments through instrument drivers. The Instrument Driver Network (IDNet) offers more than 9,000 free drivers for instruments from more than 350 third-party vendors that make your hardware work with LabWindows/CVI.

Because most of these drivers are certified by NI, they meet NI quality and usability standards and are supported by NI application engineers.

When you cannot find an instrument driver for your instrument or you want to add functionality to an existing driver, LabWindows/CVI wizards can automatically generate code to quickly create the framework you need to develop your instrument driver. LabWindows/CVI includes functions for interfacing with major instrument control standards such as GPIB, serial (RS232, RS485, and RS422), USB, VXI, PXI, Ethernet, and VISA.

Get Started Faster With the Data Acquisition Assistant

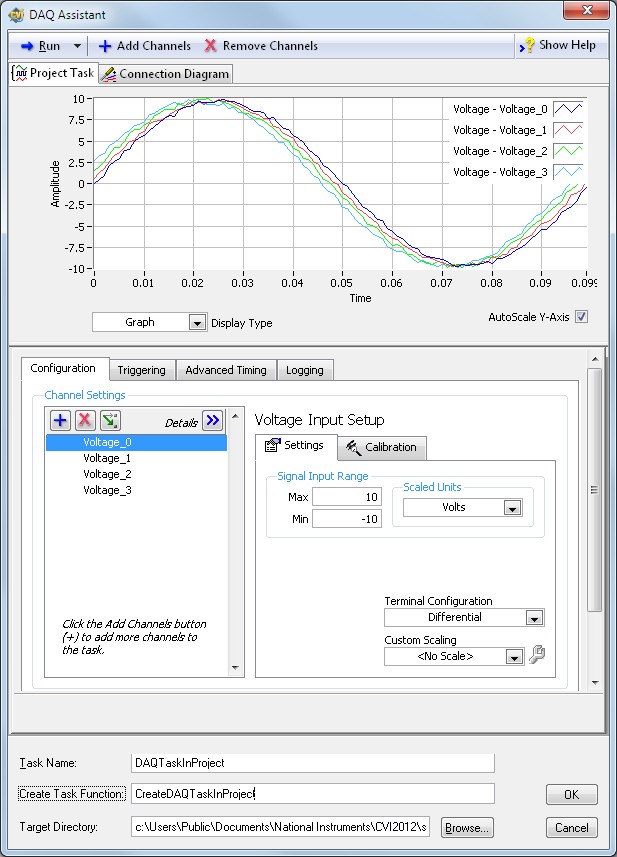

In addition to the integrated NI-DAQmx data acquisition library, LabWindows/CVI features the DAQ Assistant, an interactive interface to the NI-DAQmx driver framework. The DAQ Assistant, shown in Figure 1, interactively defines a measurement task, determines the measurement capabilities of the data acquisition device you specify, and generates code modules that contain the acquisition functionality. The tight integration of the DAQ Assistant and NI-DAQmx with LabWindows/CVI offers engineers who perform data acquisition the most efficient, productive way to take measurements in an ANSI C environment.

Figure 1: The DAQ Assistant interactively defines a measurement task, determines the measurement capabilities of the DAQ device you specify, and generates code modules containing the acquisition functionality.

Easily Test Physical Connections

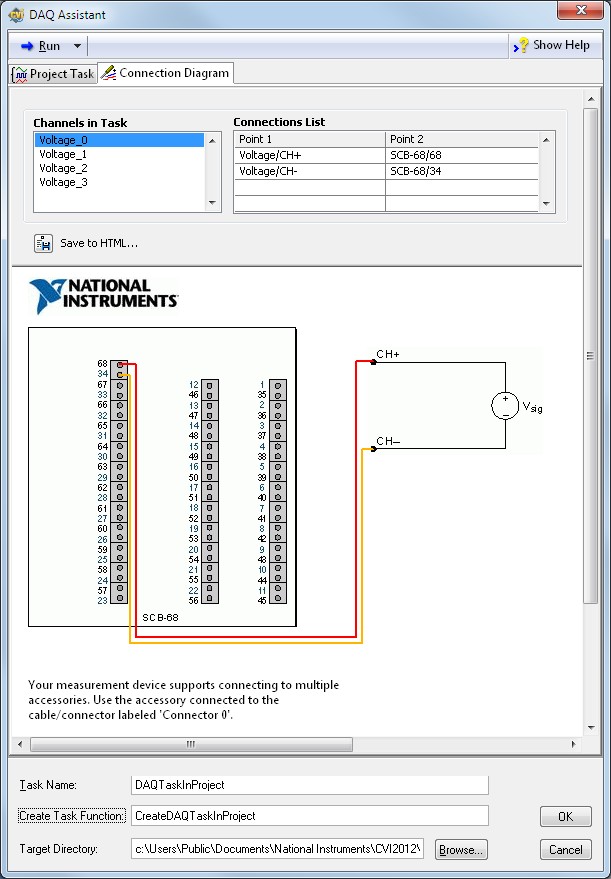

Some driver software even includes features to help you properly set up and test your physical signal connections. The NI-DAQmx driver, for example, provides connection diagrams that illustrate the various connections you need to make a particular measurement. Although referring to the user manual is a good practice, these connection diagrams can be a great time saver.

Figure 2: Some LabWindows/CVI drivers provide built-in connection diagrams to help you connect your signals.

Save Time With the Instrument I/O Assistant

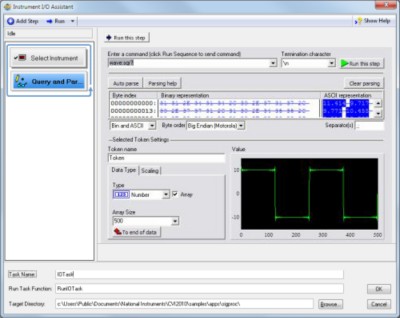

The Instrument I/O Assistant offers a simple interface you can use to quickly prototype applications and autoparse instrument data, without any programming. You can easily import the generated code into any existing application, which removes the tedium of writing instrument connectivity, basic communication, and string parsing code. By writing two lines of code, you can invoke more than 300 lines of code created by the Instrument I/O Assistant and quickly focus on taking measurements.

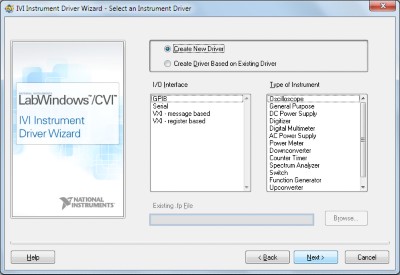

Generate Instrument Drivers With the LabWindows/CVI IVI Instrument Driver Wizard

With the IVI Instrument Driver Wizard and the IVI Custom Class Driver Wizard, you can easily create the source file; include file, and function panel file for controlling an instrument based on an existing driver for a similar instrument, the core IVI driver template, or an IVI instrument class template.

Communicate With User-Programmable FPGA Hardware

You can use LabWindows/CVI FPGA to create user-programmable FPGA hardware and then use the FPGA-Interface C API and custom function panels to simplify host application development within LabWindows/CVI.

With the FPGA-Interface C API, you can use NI LabVIEW graphical tools to program the FPGA within NI hardware and LabWindows/CVI to program the processor within the system. This feature gives engineers and scientists with ANSI C expertise the ability to use FPGAs within their designs without the burden of learning hardware design while also giving them the option to reuse their existing embedded ANSI C code.