Have You Considered a Modular Oscilloscope in Your Test System?

Overview

Whether it’s used to make a rise time measurement, measure a signal period, or identify peak-to-peak voltage, the oscilloscope has been an extremely valuable resource for test and measurement over the last 50 years. The oscilloscope is at the core of a variety of applications ranging from the test bench to rack-and-stack automated test systems. As application requirements and technology evolve, oscilloscopes have changed quite a bit since their invention and not all are created equal. New systems that use digital oscilloscopes to meet performance requirements have resulted in an acceptance of changes in oscilloscope specifications and features. With this evolution, have you considered how the recent trend toward modular instruments impacts this space?

If you haven’t considered a modular oscilloscope instead of your traditional box oscilloscope, ask yourself these questions:

- How much space is required when combining multiple instruments to get the desired channel count?

- How quickly will box oscilloscope components be obsolete or outdated?

- How often do your measurement needs change?

In this article, gain more insight into the differences between box and modular oscilloscopes.

Contents

- Remove Redundancy and Save Space While Having Full Functionality

- Keep Up With Technology Evolutions in Your System

- Choose the Functionality Specific to Your Application

- See How NI PXI Oscilloscopes Outperform Traditional Oscilloscopes

- Make the Switch to Modular Oscilloscopes

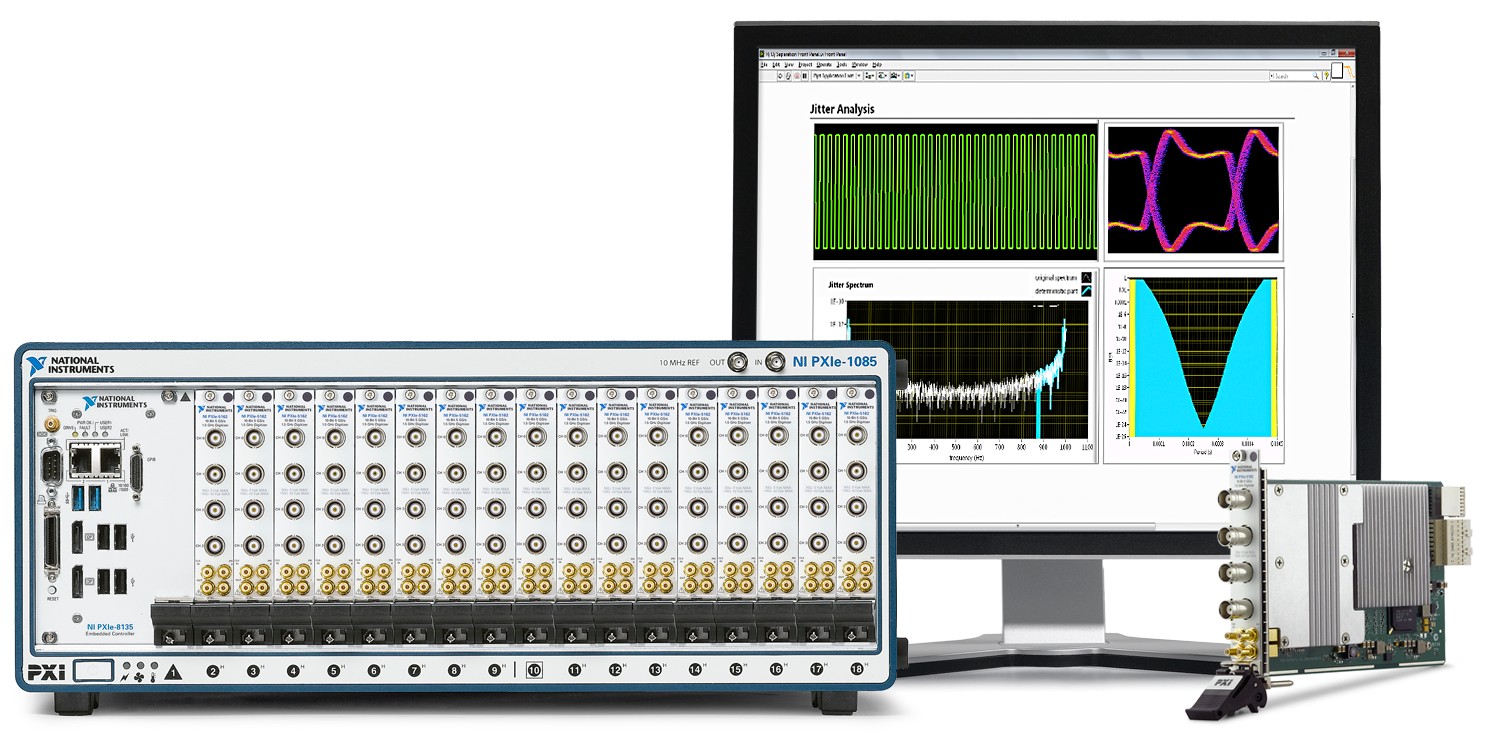

Figure 1: A modular measurement system with an 18-slot PXI Express chassis full of modular oscilloscopes.

Remove Redundancy and Save Space While Having Full Functionality

The internal components of an oscilloscope can be narrowed down to a few key areas. The most important is the data converter technology that samples at a certain frequency and with a specific resolution to digitize the signal. The results of this measurement are useless if this core element isn’t accurate. In front of the converter, you need signal conditioning to optimize the capabilities of the converter. This gives you the ability to amplify, attenuate, filter, or couple the signal so you get the best possible measurements. After you have taken the measurement, you are required to move data from the converter into some form of memory to be processed or displayed.

These key areas define the value of an oscilloscope. The remaining components within a traditional box oscilloscope are designed to either make the box function as a stand-alone device (processor, screen, power supply, OS, and so on) or give you the ability to control it (buttons, knobs, on/off switch, and so on). When the oscilloscope is the only instrument on your bench top and you intend to interact with it manually, then you’re dealing with the perfect combination of technology.

But if you have even two oscilloscopes, you have redundancy. You most likely don’t need two processors, two screens, and two power supplies to accomplish your task. Why take up all that space for no reason? This redundancy grows quickly when creating a rack–and-stack system. When evaluating this use case, there is minimal manual interaction with a running production test system, so don’t waste rack height with a display that isn’t being used.

Figure 2: Side-by-side comparison of a stack of five traditional, box instruments (left) and a PXI-based system with multiple instruments (right).

Modular oscilloscopes take the key areas for an oscilloscope (analog-to-digital converter (ADC), front-end conditioning, and memory/data interface) and put them into a card-modular format. To minimize size, you use shared PC technology to give you all the other elements of the box oscilloscope with room to add multiple modular oscilloscopes to adapt to your specific application needs or other types of instruments without redundancy, resulting in overall saved space.

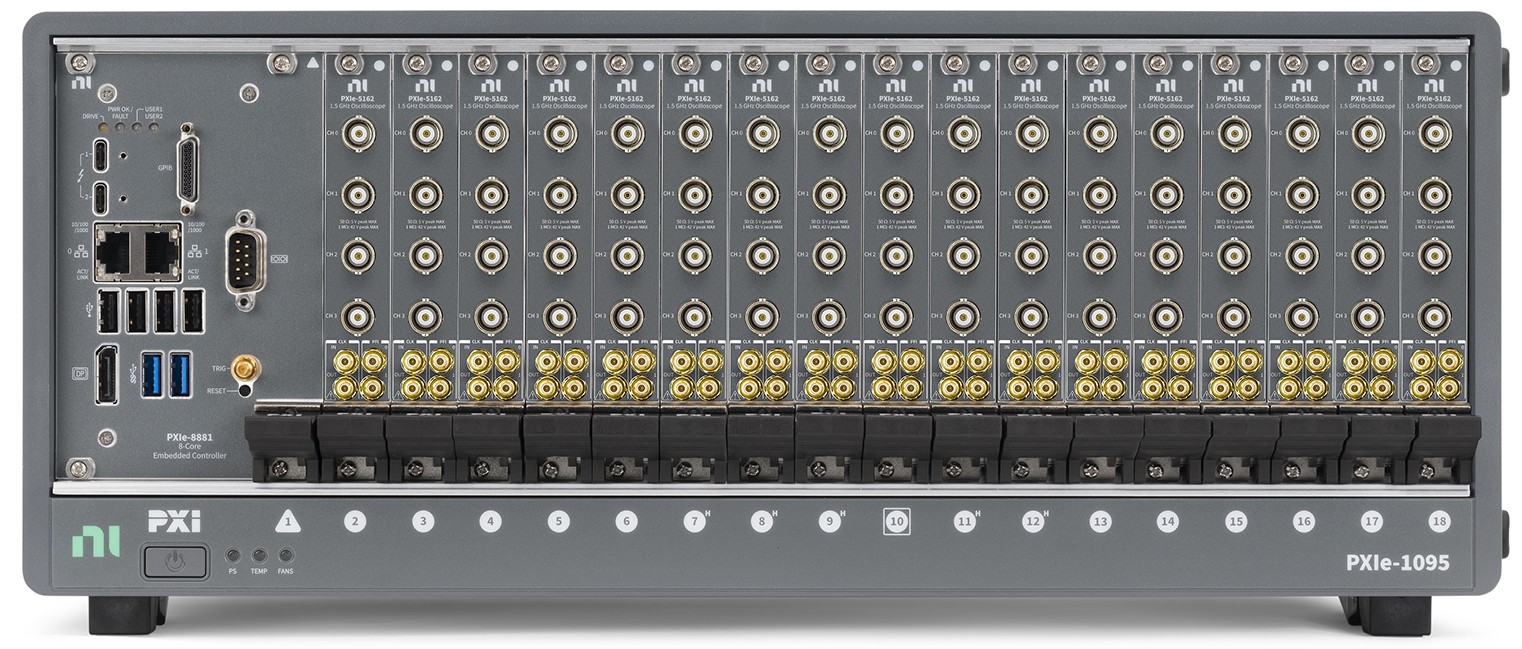

Figure 3: A 68-channel PXI-based oscilloscope system uses a single processor and power supply.

Keep Up With Technology Evolutions in Your System

All the technology within an oscilloscope does not evolve at the same rate. For example, the ADC is likely state of the art when you purchase the oscilloscope and remains so for at least months, if not years. This is also true for the signal conditioning in front of the ADC. But consider the components that are inherited from the PC industry, the processor, memory, display, and other elements. They become obsolete in days or weeks. When you’re performing a processor-intensive task, wouldn’t you like your instrument to at least have a processor similar in performance as your smartphone? If you bought your box oscilloscope five to 10 years ago, there’s a good chance it doesn’t.

One of the most processor-intensive tasks for an oscilloscope is to measure jitter. Have you considered why your jitter measurement takes so long? The processor inside the box is over 10 years old and you are unable to easily upgrade it without purchasing a new box oscilloscope. Take that same measurement on a modular oscilloscope with the same measurement technology but pair it with a modern processor and bus technology to improve that measurement time by 10X. This type of improvement is not possible with box oscilloscopes even when offloading the processing to another PC. The communication buses are low bandwidth, high latency like GPIB or Ethernet to move the data. With this setup, you are pairing adequate measurement technology to obsolete PC technology, and the speed of your measurement system suffers because of it.

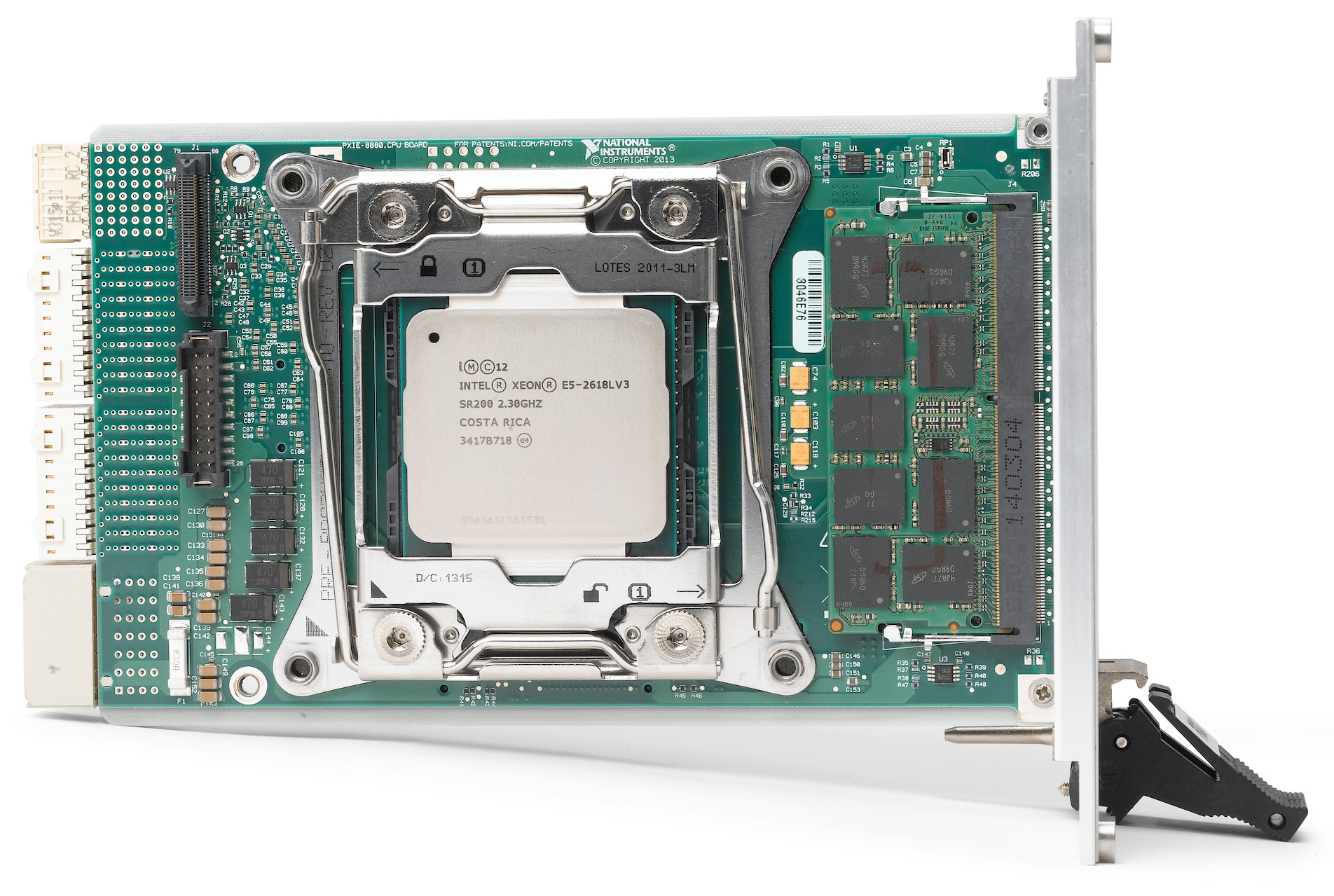

When using a modular oscilloscope, you can upgrade the system controller when you want to reduce the analysis time. Choose from the latest Xeon processor to analyze your data if speed is required. However, if you’re more concerned about system cost, choose from an inexpensive, low-profile PC. You now have the option to define the system capabilities based on what you want and need, and are no longer being tied to what the vendor specifies

Figure 4: Integrate the latest technologies such as Intel's Xeon processor directly into your test system when using the PXI modular platform.

Choose the Functionality Specific to Your Application

Your application may require you to take the same measurement as everyone else, but rarely is your complete application the same. If your needed measurements happen to be built right into a traditional box oscilloscope and you intend to make the measurement manually, then traditional solutions may work for you. But tomorrow you may not, and then what do you do?

With modular oscilloscopes, the instrument is defined by the software, and the software is completely open to you, the user. As mentioned earlier, all you really need for an oscilloscope is the ADC, front-end, and memory or a data bus. The software written on traditional oscilloscopes is written by someone to perform a turnkey operation of the product. That software might be available to you for a PC, but it often isn’t and this decision of availability is owned by the vendor. Because this software required you to rely on the data connection to the instrument, it might not refresh at a comfortable rate given the slow data connections over GPIB or Ethernet.

When you use modular oscilloscopes connected over the fastest PC bus (PCI Express), you receive all the data available in an environment where you get to manipulate the data however you want.

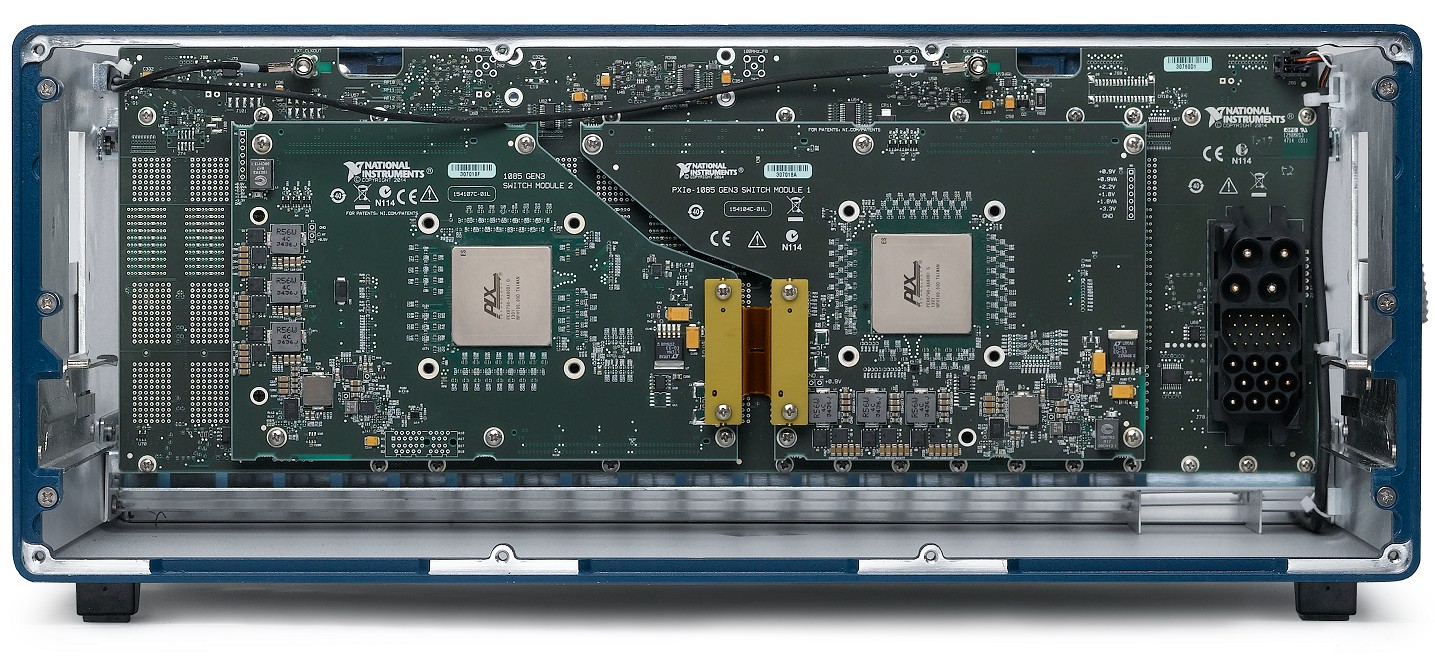

Figure 5: Rear view of the backplane of NI's high-performance chassis built on the PCI Express Gen 3 technology.

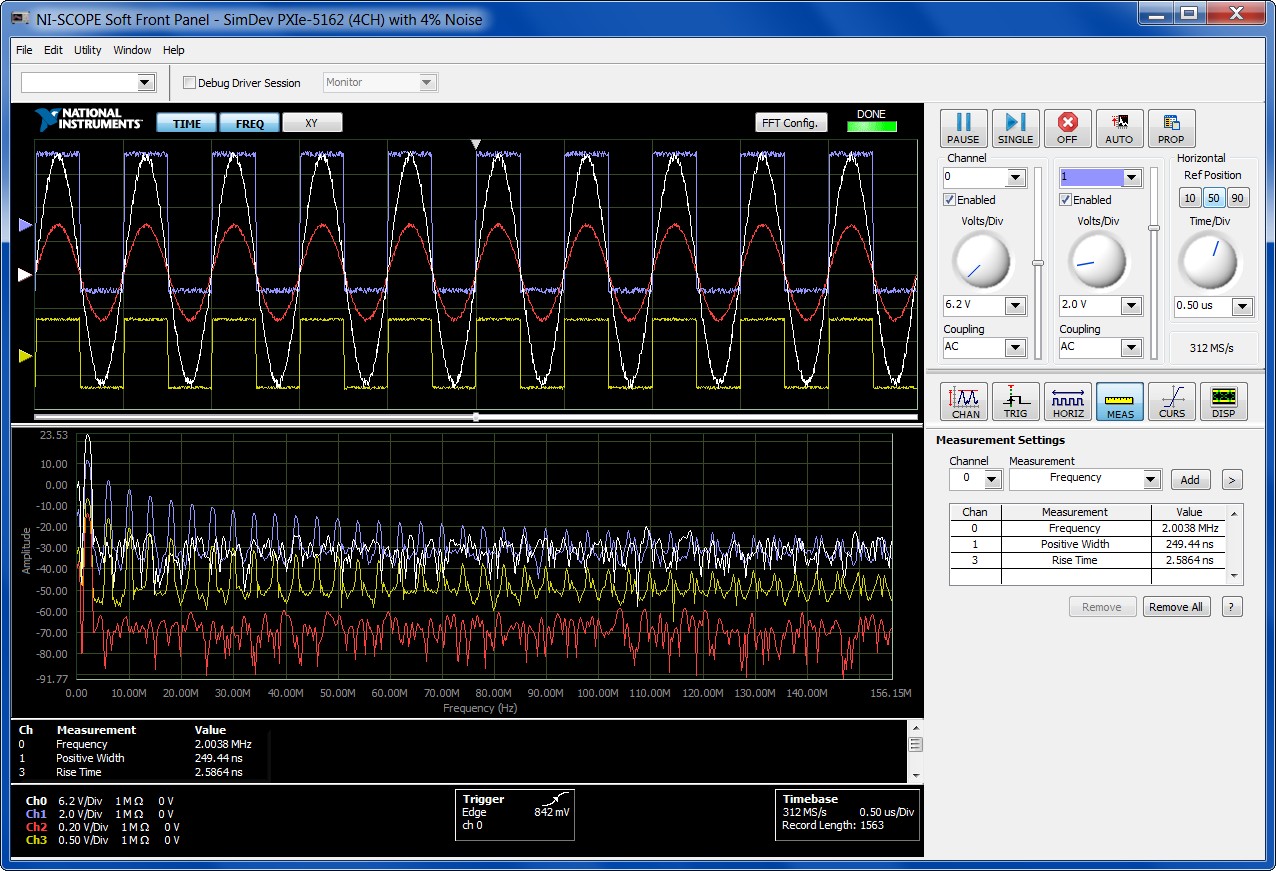

With NI LabVIEW system design software, that’s done out of the box with simple example programs or using soft front panels that provide a similar feel to a traditional box oscilloscope use model.

Figure 6: The soft front panel of an NI PXI oscilloscope which mimics the knobs and buttons of traditional instruments in software.

The newest modular oscilloscopes give you the ability to even go into the instrument and modify how the data is packaged or insert algorithms into the data stream for even more performance. The software you write becomes how the instrument works, and that ultimately makes it the most efficient instrument for your task.

See How NI PXI Oscilloscopes Outperform Traditional Oscilloscopes

Discover how PXI Oscilloscopes from NI are built for automated test to help you exceed test times achieved with a traditional oscilloscope. This video compares a PXI Oscilloscope with another oscilloscope to demonstrate the differences in the data transfer buses of the two devices, and how it makes the PXI Oscilloscope the most optimized for automated tests. You will learn about how the PXI Oscilloscope performs and its advantages in example tests for waveform acquisition, measurements, and oscilloscope reconfiguration.

Make the Switch to Modular Oscilloscopes

Just like the analog oscilloscope gave way to the digital oscilloscope, box oscilloscopes users are making the switch to a modular approach. Modular oscilloscopes provide the out-of-the-box experience of box instruments while offering a platform to support modern technology with measurement and channel capability to meet changing needs. View these resources to further explore the possibilities of a modular oscilloscope and determine whether a modular oscilloscope is the right choice for your application.