Benchmarking and Testing inspections in Vision Builder for Automated Inspection

Overview

Inspection validations tools in Vision Builder for Automated Inspection help you test the final inspection to save time debugging and troubleshooting before deployment. Vision Builder for Automated Inspection includes built in tools for benchmarking, modeling system variations, and inspection validation.

Contents

Benchmarking Inspections

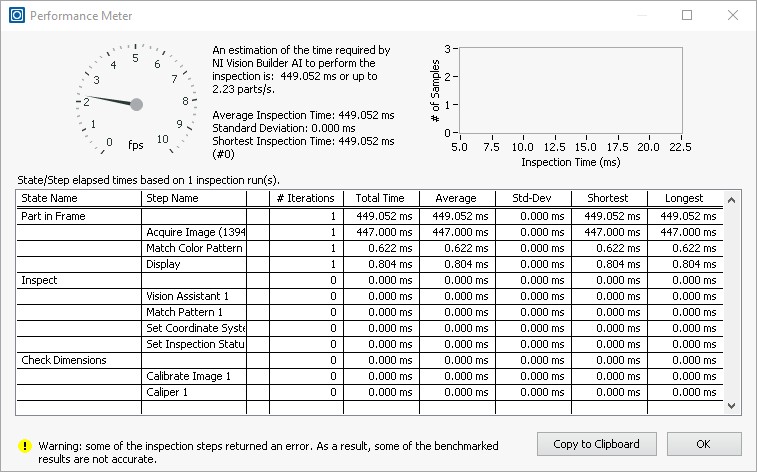

The benchmarking tool helps you measure the elapsed time of various inspections states and individual inspection steps. You can verify that the inspection meets your timing requirements and gives the granularity to troubleshoot specific steps or functions that may be increasing the inspection time.

Figure 1: Inspection Benchmark Results

Modeling System Variations

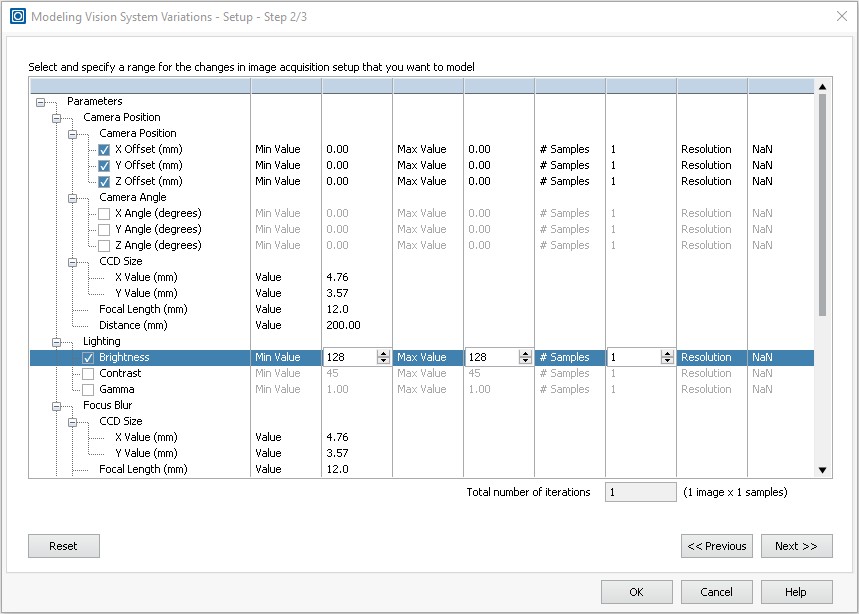

The deployment environment of an inspection system on a production floor, to a machine, or into a test cell can have slight variations from the test environment or even variations during day-to-day operation. VBAI includes a vision system variations modeling tool to help you simulate an offset in camera position or changes in the lighting and focal length so you can predict how your system will react to these changes and account for them in your inspection.

Figure 2: Parameters available to Model Vision System Variations

Validate Inspections

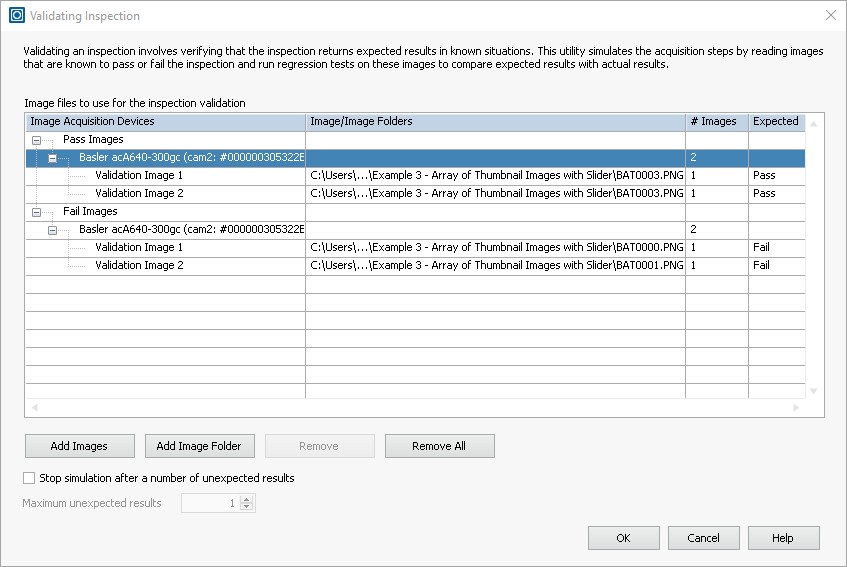

After building an inspection system using test images, you can validate the inspection by quickly cycling through known batches of pass and fail images. By debugging your inspection and validation with VBAI, you can have confidence in the results after deployment.

Figure 3: Setting up Pass/Fail Images for Regression Testing

Additional Resources

- Now that you have learned how VBAI can help you benchmark, and model inspection results you can download an evaluation.

- Do you need cameras, frame grabbers, lighting, or computer hardware for image processing? Check out NI vision hardware to select the right vision hardware for your inspection system.