Sensors for Condition Monitoring

Overview

Measurement Technologies and Sensors for Condition Monitoring Applications

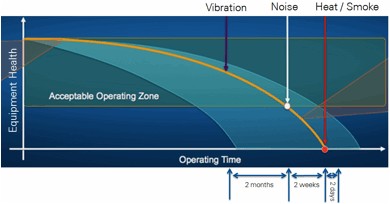

Many sensors detect changes in equipment components. Vibration sensors are the most commonly used sensors when monitoring rotating machinery. They are often credited for sensing the mechanical degradation of equipment components two months or so in advance of a failure, as shown in Figure 1.

Figure 1: Asset degradation can be detected in advance by using sensors.

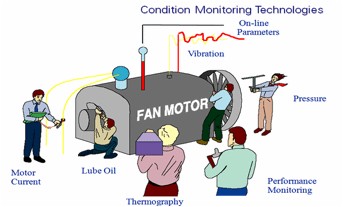

Other sensing technologies used in equipment condition monitoring as shown in Figure 2 include motor current, oil analysis, thermography, dynamic pressures, and operating state sensors such as speed.

Figure 2. A variety of condition monitoring technologies help asset specialists understand asset health.

Table 1 lists the types of sensors and sample vendors used in condition monitoring.

| Measurement | Sensor | Frequency Range | Possible Signal Conditioning Needs | Vendors |

| Vibration | Accelerometer | >100 Hz | IEPE AC/DC coupling ±24 V input or AC couple Anti-alias filter | IMI Sensors Connection Technology Corporation Endevco/Wilcoxon |

| Vibration | Velocity | >20 Hz to <2 kHz | IEPE AC/DC coupling ±24 V input or AC couple Anti-alias filter | IMI Sensors Connection Technology Corporation Endevco/Wilcoxon |

| Vibration | Proximity Probe (Displacement) | <300 Hz | Modulator/demodulator Anti-alias filter ±30 V input range | Connection Technology Corporation |

| Speed | Proximity Probe | <300 Hz | Modulator/demodulator Anti-alias filter ±30 V input range | Connection Technology Corporation |

| Speed | Magnetic Zero Speed | Up to 15 kHz | 24 V DC power ±20 V | Honeywell SPECTEC |

| Motor Current | Current Shunt Current Clamp | Up to 50 kHz | ±333 mV or ±5 V | Magnelab |

| Temperature | RTD Thermocouple | Up to 10 Hz | Noise rejection, excitation, cold-junction compensation | NI |

| Temperature | Infrared Camera | Multiple frames per sec | GigE Vision over EtherNet connection | FLIR Systems |

| Pressure | Dynamic Pressure | >100 Hz | AC/DC coupling IEPE (some models) ±24 V or AC coupling Anti-aliasing filter | Endevco PCB Kulite Kistler |

Oil Quality Oil Particulate | Viscosity Contamination Particulates | Up to 10 Hz | mA current input ±10 V input 50/60 Hz noise rejection | Kittiwake Honeywell HYDAC Poseidon Systems |

| High-Frequency “Noise” | Ultrasonic | >20 kHz | AC/DC coupling ±24 V input range Anti-aliasing filter | UE Systems |

Table 1: There are a variety of measurements, signal condition needs, and vendors for condition monitoring sensors.

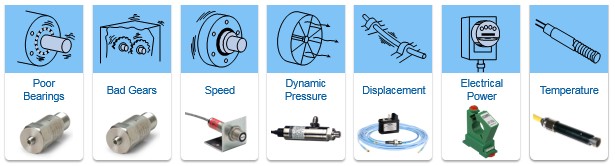

Figure 3 shows a typical sensor and a sample failure mode of an asset the sensor monitors.

Figure 3: Typical sensors and failure modes that can be detected.

Each sensor offers the ability to monitor the degradation of mechanical and electrical components within rotating machine equipment.

- Vibration sensors are used to detect roller bearing wear, gearbox wear, shaft misalignment, unbalance, and mechanical looseness.

- Speed sensors work with vibration sensors to correlate vibrations to rotating speed and shaft angular position.

- Motor current sensors are commonly placed at the motor control center. They can detect eccentric rotors, loose windings, rotor bar degradation, and electrical supply unbalance.

- Dynamic pressure sensors are used for combustion dynamics, flow turbulence, and cavitations.

- Temperature sensors are typically used to detect heat caused by friction. They often accompany vibration sensors to collaborate vibration-detected degradation.

- Thermal imaging detects hundreds of temperatures within the camera’s field of view.

- Ultrasonic sensors can detect electrical problems including corona, arcing, and tracking. They can also be used to detect early signs of roller bearing wear.

- Oil sensors can detect wear debris from bearings and gears. They also can detect contaminants in the oil that reduce the lubrication ability of the oil.

Once you have identified equipment, failure modes, and sensors, the next step is to choose measurement hardware to digitize the sensors. Your choice of measurement hardware depends on your sensor characteristics including frequency range, voltage range, and signal conditioning needs.

With respect to frequency range, you can choose from two types of sensors: static and dynamic. Dynamic sensors measure frequency ranges well above 2 Hz. For example, a typical accelerometer has a frequency range of 1 Hz or 2 Hz to 15 kHz or 20 kHz. The ultrasonic sensor frequency range extends to 100 kHz or more, with a heterodyne output ranging from a few hundred hertz to 40 kHz. On the contrary, static sensors convert the monitored physical property into an electrical signal at rates of 1 Hz to 10 Hz or 20 Hz.

The other two sensor characteristics are voltage range and signal conditioning needs. Some sensors produce a voltage as high as 30 V, while others might produce only a few millivolts. Some sensors need sensor power such as IEPE power, while others might need cold-junction compensation. Table 1 lists the common signal conditioning needs for each measurement and sensor.

NI provides a wide range of hardware to acquire data from these sensors as well as the software to process and analyze the data. For deployment-ready software that connects to these sensors, please see the link below.