4-20 mA Current Loop Fundamentals, System Design, and Setup

Overview

Since the 1950s, current loops have been used to transmit transducer data for process monitoring and control. With their low implementation cost, inherent resistance to noise, and ability to carry signals long distances, 4-20 mA (milliamp) current loops have proven particularly well-suited for industrial environments. This white paper focuses on current loop fundamentals, system design, and setup.

Contents

- Current Loop Fundamentals

- Designing a Current Loop System

- Current Loops: Beyond the Basics

- Current Measurement Products from National Instruments

Current Loop Fundamentals

Using Current to Transmit Transducer Data

Industrial-grade transducers commonly use current signals to transmit data. This is in contrast to most other transducers, such as thermocouples and resistive strain gages, which use a voltage signal. While voltage-based transducers are sufficient in many environments, current-based transducers are at times preferred. For instance, the inherent disadvantage of using voltage to transmit signals in an industrial environment is voltage drops over long cable lengths due to wire resistance. You can use high input impedance devices to circumvent signal loss. However, these devices are sensitive to the noise induced by nearby motors, conveyor belts, and radio transmissions.

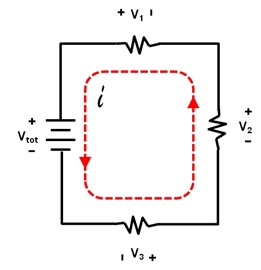

Kirchhoff’s current law (KCL) states that the sum of currents flowing toward a point is equal to the sum of currents flowing away from that point. In theory, all current present at the beginning of a loop must reach the end as demonstrated in Figure 1.

Figure 1. According to Kirchhoff’s current law, all current present at the beginning of a loop must reach the end.

This is the basic principle on which a current loop operates. Measuring current at any position along a single loop produces the same result. By using current signals and low impedance data acquisition devices, industrial applications benefit from better noise immunity and longer transmission cable lengths.

Current Loop Components

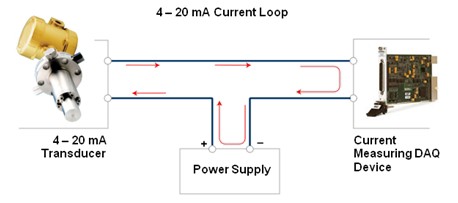

The main components of a current loop include a DC power supply, transducer, a data acquisition device, and wires connecting them together in a series, as shown in Figure 2.

Figure 2. Current Loop System

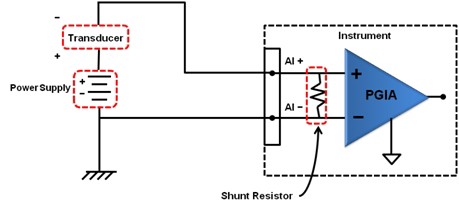

The DC power supply provides the power to the system. The transducer regulates the flow of current through the wires at 4 to 20 mA, where 4 mA represents a live zero and 20 mA represents the maximum signal. A 0 mA signal signifies a break in the loop. The data acquisition device measures the regulated current flow. An effective and accurate method of measuring current is to place a precision shunt resistor between the leads of the data acquisition device amplifier (in Figure 2) to convert the current signal into a voltage measurement to ultimately be related back to the transducer’s original measurement.

To help better understand current loops, consider the design of an example system using a transducer throughout this white paper. System specifications include the following:

- Transducer needs to measure pressure

- Transducer is located 2000 ft away from the measurement device

- A current measuring the data acquisition device provides an operator with feedback about the transducer measurements

This example begins with determining an appropriate transducer for the application.

Designing a Current Loop System

Choosing a Transducer

The first step in designing a current loop system is selecting a transducer. Beyond the type of measurement (flow, pressure, temperature, and so on), an important consideration in choosing any transducer is the operating voltage. A voltage source provides power to the current-based transducer, allowing it to regulate the flow of current through the wires. To maintain transducer functionality, the voltage supplied should be no less than the minimum required; likewise, supplying more voltage than the maximum specified can damage the transducer.

For the example current loop system, your chosen transducer measures pressure and has an operating voltage of 12 to 30 V. With the transducer selected, properly measuring the current signal is required to provide an accurate representation of the pressure applied to the transducer.

Choosing a Current Measuring Data Acquisition Device

An important aspect of building a current loop system is avoiding ground loops. A common method of preventing ground loops with a measuring data acquisition device is isolation. With isolation, you can avoid ground loops such as the one in Figure 3.

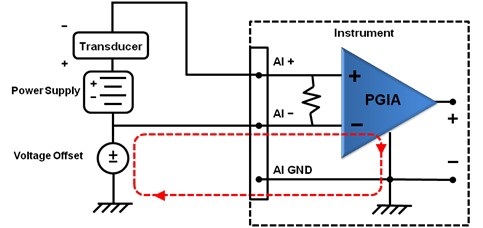

Figure 3. Ground Loop

Ground loops are created when two connected terminals in a circuit are at different ground potentials. This difference causes current to flow in the interconnection, which can produce offset errors.

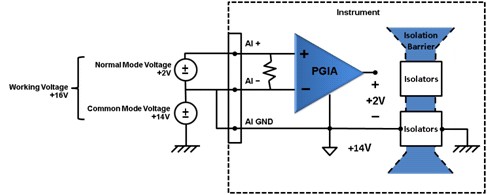

Isolating the data acquisition device is a means of electrically separating signal source ground from the amplifier ground of the data acquisition device, as shown in Figure 4. Because current cannot flow across the isolation barrier, the amplifier ground reference can be at the same potential as the signal source ground. Thus, you cannot inadvertently create a ground loop.

Figure 4. Common- and Normal-Mode Voltage with Isolation

Isolation also prevents large common-mode voltages from damaging data acquisition devices. Common-mode voltage is the voltage present on both the positive and negative inputs of an instrumentation amplifier. For example, both + and – pins of the data acquisition device in Figure 4 are on top of +14 V of common-mode voltage. Many data acquisition devices have a maximum input range of ±10 V. If the data acquisition device has no isolation and the common-mode voltage is outside the maximum input range, you may damage the device. Even though the normal-mode voltage in Figure 4 is only +2 V with a +14 VDC offset, the resulting working voltage is +16 V (normal-mode voltage is the voltage difference between the + and – pins; working voltage is normal- and common-mode voltage added together). This would be a hazardous voltage level to a data acquisition device with a smaller working voltage.

With isolation, the amplifier ground reference is electrically separated from earth ground. As in Figure 4, the amplifier ground reference may be level-shifted to match the +14 V. Raising the amplifier ground reference to +14 V effectively shifts +16 to +2 V at the data acquisition amplifier. Now the data acquisition device is no longer at risk of overvoltage damage. (Note that isolators have a maximum common-mode voltage they can reject.)

With the current measuring data acquisition device isolated and protected, matching a power supply is the last step in completing a basic current loop system.

Choosing a Power Supply

Discovering which power supply best meets your requirements is simple. In a current loop, the power supply must emit voltage equal to or greater than all the voltage drops in the system combined.

The data acquisition device for this example uses a precision shunt resistor to measure current. You need to calculate the voltage drop across the resistor. A typical shunt resistor is 249 Ω. Implementing basic calculations with the 4 to 20mA current loop shows the following:

With this 249 Ω shunt resistor, you can map current to a range of 1 to 5 V, allowing the data acquisition amplifier’s voltage reading to be related to the pressure transducer’s signal.

The pressure transducer from above requires a minimum operating voltage of 12 V with a maximum of 30 V. Adding the voltage drop of the precision shunt resistor to the transducer yields the following:

This suggests that a 17 V power supply suffices. However, the current loop wire’s internal resistance creates an additional load on the power supply.

In applications where a transducer is far away from the measuring instruments, you must factor wire resistance into the loop power calculations. Copper wires have a DC resistance that is directly proportional to their lengths and diameters (gauge). With the pressure transducer from the example system, you need to calculate the 2000 ft distance in the power requirements. With 24-gauge solid copper wire, the internal resistance is 2.62 Ω/100 ft [1]. This resistance calculation becomes:

At 2000 ft away, there is a 1.05 V drop along the wire. To complete the loop, you need two wires, effectively doubling the length to 4000 ft:

In total, approximately 2.1 V is lost due to wiring when the pressure transducer is 2000 ft away from the data acquisition device. Combining all the voltage drops results in the following:

If you used a 17 V power supply to drive the previous setup, the pressure transducer voltage would be below the minimum operating level for a transducer due to natural wire resistance and shunt resistor requirements. Choosing a common 24 V power supply meets the power requirement of the pressure transducer system. If desired, there is enough voltage to place the pressure transducer at a further distance.

With the transducer, data acquisition device, cable lengths, and power supply properly matched, the simple pressure transducer loop system is complete. For larger applications, you can incorporate additional measurements into the system.

Adding More Transducers and Instruments

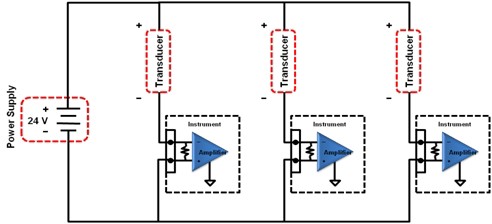

For larger applications, you can add more transducers and instruments in parallel to the power supply, as shown in Figure 5.

Figure 5. Adding More Transducers

Because you add the extra current loops in parallel, the power supply’s voltage doesn’t need to change; you only need to make sure it can source the required current. You can mix and match different types of transducers as long as each transducer and power supply’s operating voltage match. In the previous example, as long as the new transducer’s maximum operating voltage is not lower than the power supply’s 24 V, you can add the new transducer in parallel.

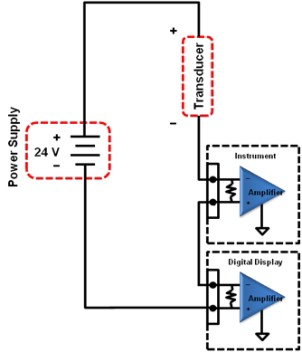

At times, you may need multiple current measuring data acquisition devices to measure the same signal. To add another data acquisition device to the same transducer, you must place the new instrument in series with the particular loop. For this example, you add a simple digital current loop meter with the existing data acquisition device, as shown in Figure 6.

Figure 6. Adding an Extra Instrument to a Transducer

Each time you add a current-measuring data acquisition device in series with the transducer, you must recalculate the total voltage requirement to ensure that the power requirements of the loop are still within specification. In this example, the new current meter uses a 105 Ω precision resistor:

With a 105 Ω shunt resistor, the current meter requires a maximum of 2.1 V, so the total voltage requirement of the system becomes:

Because adding the meter brings the total voltage requirement to only about 21.2 V, the 24 V power supply previously recommended is still sufficient for the application.

With minor calculations and additional hardware, you can quickly expand a current loop system’s application base. Also, with newer standards and types of transducers, you can extend the measurement capabilities of existing current loop infrastructures.

Current Loops: Beyond the Basics

Digital signaling developments have broadened the current loop's application space and delivered more functionality to an already robust, low-cost system.

The Highway Addressable Remote Transducer (HART), developed by Rosemount Inc., is a digital signaling protocol that can run concurrently with existing current loop systems. With digital signaling, HART-enabled transducers allow responses to proprietary commands to perform certain actions or reply with a status beyond the 4 to 20 mA current signaling. Using this technology, industrial automation and control applications can actively monitor and respond to situations by communicating between intelligent field instruments and host systems.

For specialty applications such as magnetic flowmeters, 3-wire (Type 3) and 4-wire (Type 4) transducers are also available.

Type 3 transducers provide two transducers packaged in one. These transducers are designed and installed in the same manner as the 2-wire transducers explained in this white paper.

Type 4 transducers provide separate connections for power and current measurements. Because 4-wire transducers decouple power from the measurement system, the need for an isolation requirement at the measuring data acquisition device is lifted. A drawback of 4-wire transducers, though, is that the power source requires a separate pair of wires that must run the cabling distance. This causes many applications to place the power source near the transducers.

Learn more about Type 3 and Type 4 transducers.

Current Measurement Products from National Instruments

Current loops are ideal for industrial environments where long cable lengths are required or large amounts of electromagnetic interference exist between the transducer and data acquisition device. Whether automating a factory floor or taking field measurements, you can find a variety of NI isolated current measuring devices across different platforms to meet your application needs. Isolation capabilities are typically called out in the NI online catalog, but please refer to the device specifications for details. Recommended options are included as part of the C Series Current Input Module, PXI Multifunction I/O Module, and Multifunction I/O Device products, or you can explore other current measurement options.

NI CompactRIO – Reconfigurable Embedded Control and Acquisition System

| |

NI CompactDAQ – Modular Data Acquisition System

| |

Related Links

Isolation Technologies for Reliable Industrial Measurements

How to Minimize Errors for Low-Current Measurements

Learn more about making DC and AC Current Measurements with a DMM