Integrating Vision Systems with Other Hardware and Measurements

Overview

The Vision Development Module and Vision Builder for Automated Inspection (VBAI) include capabilities for integration with additional hardware. You can correlate measurements, communicate with NI data acquisition hardware, and interface with industrial hardware like PLCs, lighting controllers, and more.

Contents

- Choosing the Right Hardware for Your Application

- Connecting to Hardware with LabVIEW and the Vision Development Module

- Connecting to Hardware with VBAI

- Additional Resources

Choosing the Right Hardware for Your Application

With multiple hardware platforms, you have the flexibility to choose the right hardware for your specific vision system and develop the software from a single tool. You can run software from the Vision Development Module on the Windows or Linux Real-Time OSs and on CompactRIO and PXI Controllers. View NI vision hardware here.

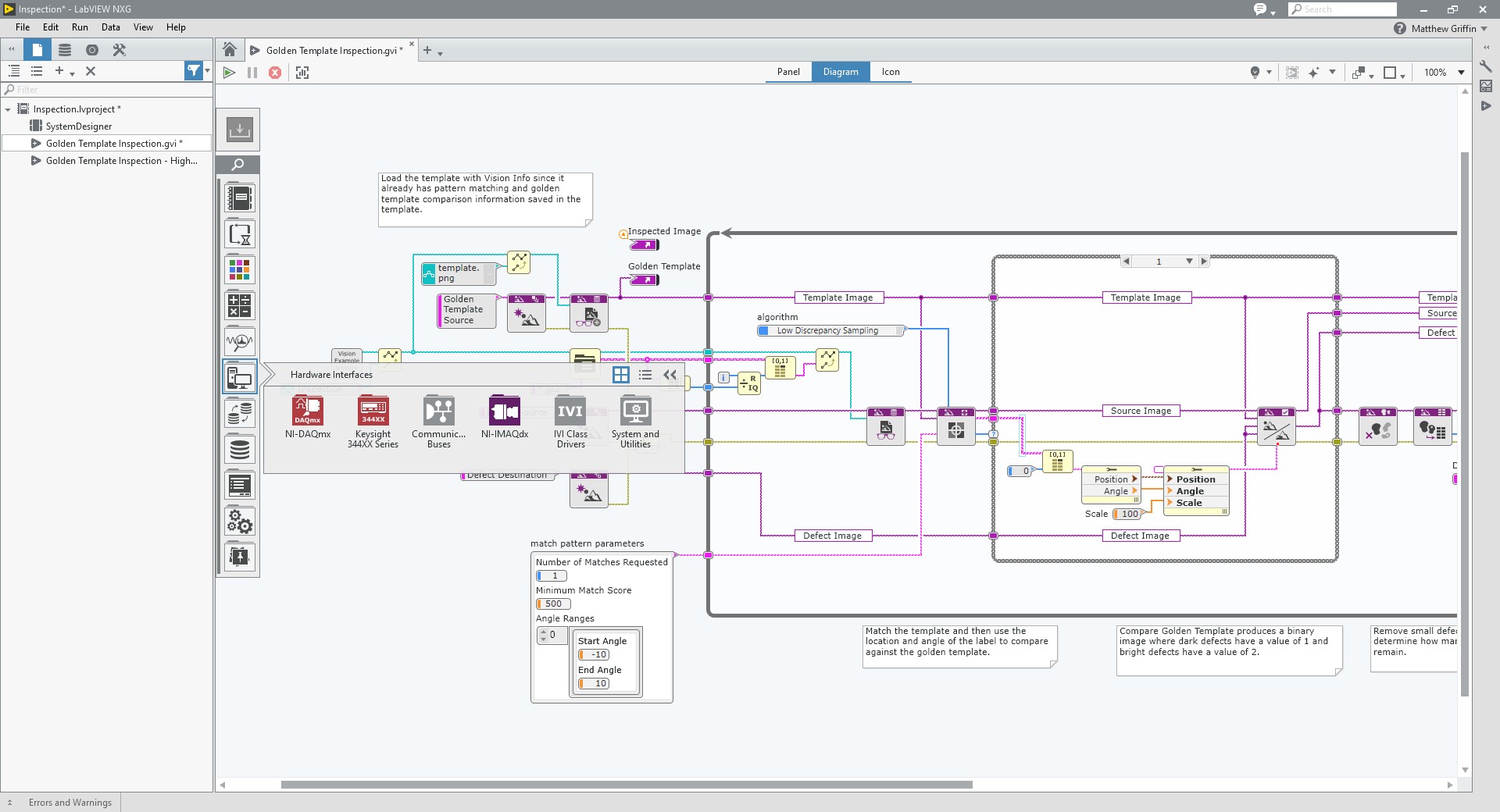

Connecting to Hardware with LabVIEW and the Vision Development Module

Using LabVIEW and the Vision Development Module, you can connect to a variety of hardware in your machine vision system. This helps you develop all the software for a machine vision system from a single software environment. You can connect with NI data acquisition hardware using the NI-DAQmx driver and industrial hardware using communications protocols like Modbus, EtherNet/IP, PROFINET, and more. You can reliably correlate image analysis with other measurements and I/O in your system or send control signals and commands to additional hardware based on your inspection results.

Figure 1: Controlling Digital Output on CompactDAQ Hardware Based on Vision Inspection Results

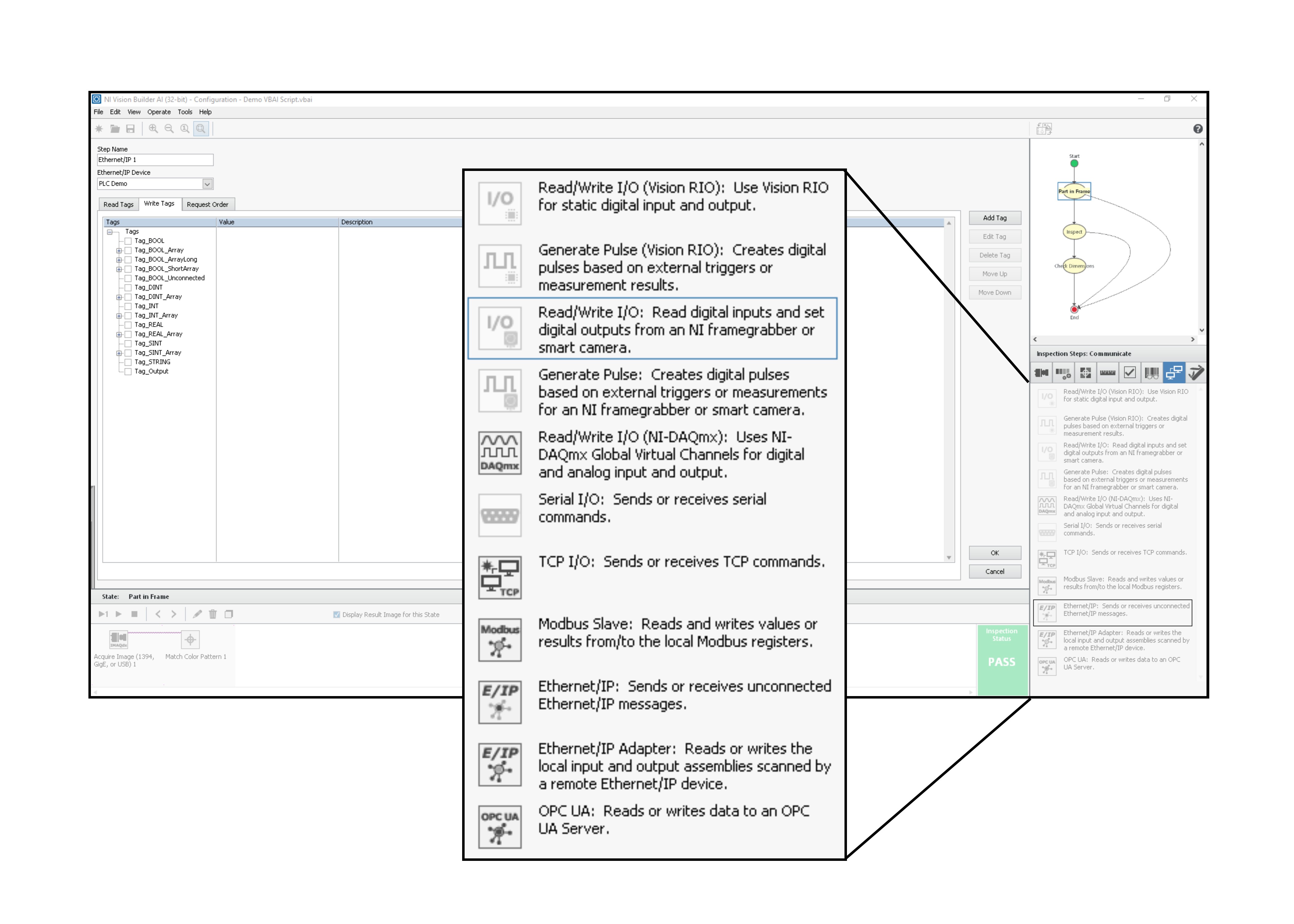

Connecting to Hardware with VBAI

VBAI has built-in steps to help you communicate with hardware. You can select the communication protocol or driver that you need to use and then configure the information you want to communicate, like sending a command to a programmable logic controller. Simply select the communication protocol that you want to use and then configure the communication in VBAI.

Figure 2: Communication Buses available in VBAI

Additional Resources

- Now that you have learned about integrating hardware into your Vision systems, you can download an evaluation for Vision Development Module or VBAI

- Do you need cameras, frame grabbers, lighting, or computer hardware for image processing? Check out NI vision hardware to select the right vision tools for your inspection system.