Processing and Analytics With CompactRIO: The Ultimate Multipurpose Controller

The Industrial Internet of Things (IIoT) is generating massive amounts of data -- more than ever before. At CERN, for example, the Large Hadron Collider generates 40 terabytes of data every second. But having the data is not enough – its what you do with the data, and the insights and outcomes that you achieve from the data, that are most important. In the midst of this explosion of engineering and measurement data, having a sound strategy for data management and analytics is critical. Because of this, best-in-class measurement and analytics solutions must have two fundamental capabilities: (1) analytics at the edge and (2) analytics across the enterprise.

Figure 1. To manage massive amounts of Big Analog Data like those generated at CERN, engineers and scientists must implement best-in-class measurement and analytics solutions that have two fundamental capabilities: (1) analytics at the edge and (2) analytics across the enterprise.

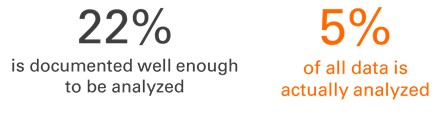

As we are faced with more and more data, the traditional approach of collecting all available data, logging it to disk, and analyzing it offline will cease to be effective. Engineers are already facing issues with this approach today. It is estimated that only 22 percent of all acquired data is documented well enough to be analyzed. Furthermore, it is also estimated that of all data, only five percent is actually analyzed.1 This problem is exacerbated when data collection is manual. Companies can spend up to 5X more time manually collecting their data than they do analyzing it.

Figure 2. Only 22 percent of all acquired data is documented well enough to be analyzed, yet only five percent is actually analyzed.

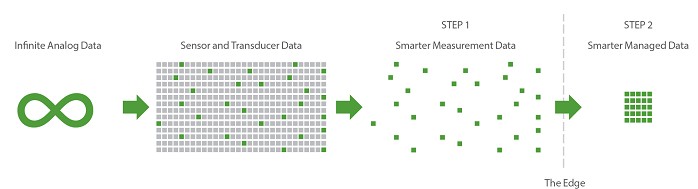

In the IIoT, engineers and scientists will be pushed to make smarter, more informed decisions -- and faster than ever before. The first step to this is to be smarter about how you address the Big Analog Data challenge by letting go of traditional data processing practices. Instead of acquiring data, sending it to a central location, processing it, and returning the result – a process with high latency -- move the processing to the edge or directly at the sensor. Here data can be analyzed and processed immediately with extremely low latency.

Figure 3. Moving your processing to the edge allows you to more intelligently manage your data at the sensor, and across the enterprise.

The CompactRIO platform is ideal for addressing this need, providing the ability to process and analyze acquired data in real time locally as well as across the entire enterprise to make informed decisions fast. With CompactRIO, you can leverage hundreds of built-in signal processing, analysis, control, and mathematics functions to accelerate the development of your application. These libraries can be used across both the processor and the FPGA allowing you to adapt to the specific needs of your application. Whether the task is advanced analysis, high-speed event detection, or signal or image processing, CompactRIO allows you to handle the task directly at the edge, making CompactRIO the most flexible intelligent edge device available.

Figure 4. CompactRIO allows you to process and analyze acquired data in real time locally as well as across the entire enterprise to make informed decisions fast.

However, solving the Big Analog Data challenge goes beyond having smarter measurement data at the edge. Not all data can be processed at the edge – some data needs to be passed onto the enterprise or to the cloud for further analysis and/or storage. The CompactRIO platform allows you to be smarter with your measurement data, and when combined with enterprise software tools like DIAdem and SystemLink TDM DataFinder Module you can create a complete, smart technical data management solution.

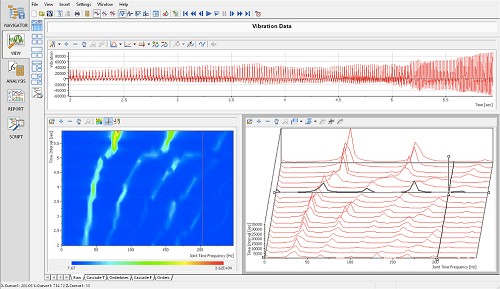

SystemLink TDM DataFinder Module is a centralized data management software which allows those collaborating within organizations to quickly find and retrieve information based on their data files. SystemLink TDM DataFinder Module works out of the box by indexing data files in specified folders on computers or across an entire network without extended IT support or database specific knowledge. The data index builds, maintains, and scales automatically as your files change. With a data management plan in place you can conduct further advanced analysis on the data. DIAdem is a software tool you can use to quickly locate, load, visualize, analyze, and report measurement data collected during data acquisition and/or generated during simulations. It is designed to meet the demands of today’s complex systems, which require you to quickly access, process, and report on large volumes of scattered data in multiple custom formats to make informed decisions faster. In conjunction with SystemLink TDM DataFinder Module, DIAdem allows you to create queries to quickly locate your data, interactively visualize your data, conduct further engineering analysis with hundreds of built in functions, create custom reports, as well as create automation scripts so that you can fully automate your data analysis.

Figure 5. Combining the CompactRIO platform with DIAdem and SystemLink TDM DataFinder Module provides an end-to-end data analytics solution.

The combination of edge processing with the CompactRIO platform, and end to end analytics across the enterprise and cloud with DIAdem and SystemLink TDM DataFinder Module delivers a world class solution to the Big Analog Data challenge.

Next Steps

Improve the integration and performance of your next processing and analytics application with CompactRIO: The Ultimate Multipurpose Controller. Explore how the CompactRIO Controller can also be used for logging and monitoring. Learn more about the CompactRIO platform, or read about the CompactRIO Controller.

1EMC Digital Universe with Research and Analysis by IDC -- The Digital Universe of Opportunities: Rich Data and the Increasing Value of the Internet of Things.