Reduce Risk with the CompactRIO Platform

Overview

Reduce your risk by leveraging the 1000s of person-years invested in proven, validated, certified, rugged, industrial and machine hardware/software platforms from NI that have been deployed by 10,000s of customers in every environment on earth. Wide-temperature range, thermal, shock and vibration testing, EMC/ESD, industry certifications, etc. are all areas of high-value that NI provides across the CompactRIO Platform and includes the fully integrated run time software. Risk mitigation is also accomplished through a wide-range of services, outstanding customer support and the industry’s most extensive ecosystem. By partnering with NI as your supplier, risks in your control and I/O subsystem design are greatly minimized. With NI, you build superior industrial equipment and machines not only faster, but at reduced risk. Risk in the scope of this paper is defined as selecting the right supplier/partner for your control and I/O sub-systems.

Contents

- The Importance of a Proven Platform

- Core vs Context and Mission Criticality

- Why NI is Your Best Partner to Reduce Risk for Mission-Critical Solutions

- Next Steps

The Importance of a Proven Platform

We use the word proven as it embodies and expresses in a single word many key elements, concepts and proof points that address risk. These are grouped into the following:

- NI Proven

- Our demanding approach to how we develop, validate, qualify and certify our products.

- Supplier Proven

- Many of our suppliers also take a demanding approach to building the products we use

- Partner Proven

- Large ecosystem of partners who have built their business and reputation on NI products

- Industry/ Ecosystem Proven

- Industry standards to validate, qualify and certify our products

- Customer Proven

- Products based on NI platforms are deployed by 10,000s of customers underground, undersea, on ground, in the sky, on every continent, in every environment, on Earth

NI Proven

NI provides immense value to customers in our demanding approach to how we design, develop, validate, qualify and certify our products. By leveraging and re-using our products, customers increase their efficiency while reducing costs, time and risk yet still retaining the capability to customize and innovate to differentiate themselves in the marketplace.

Modern, high-end embedded design is hard (i.e. high clock-rate CPUs, FPGAs, complex DRAM interfacing, high speed analog and digital with <= 1mm pitch, ball grid array, 1000+ pin packages on 12+ layer boards) – certified for real-word, harsh industrial environments raises the difficulty bar even higher.

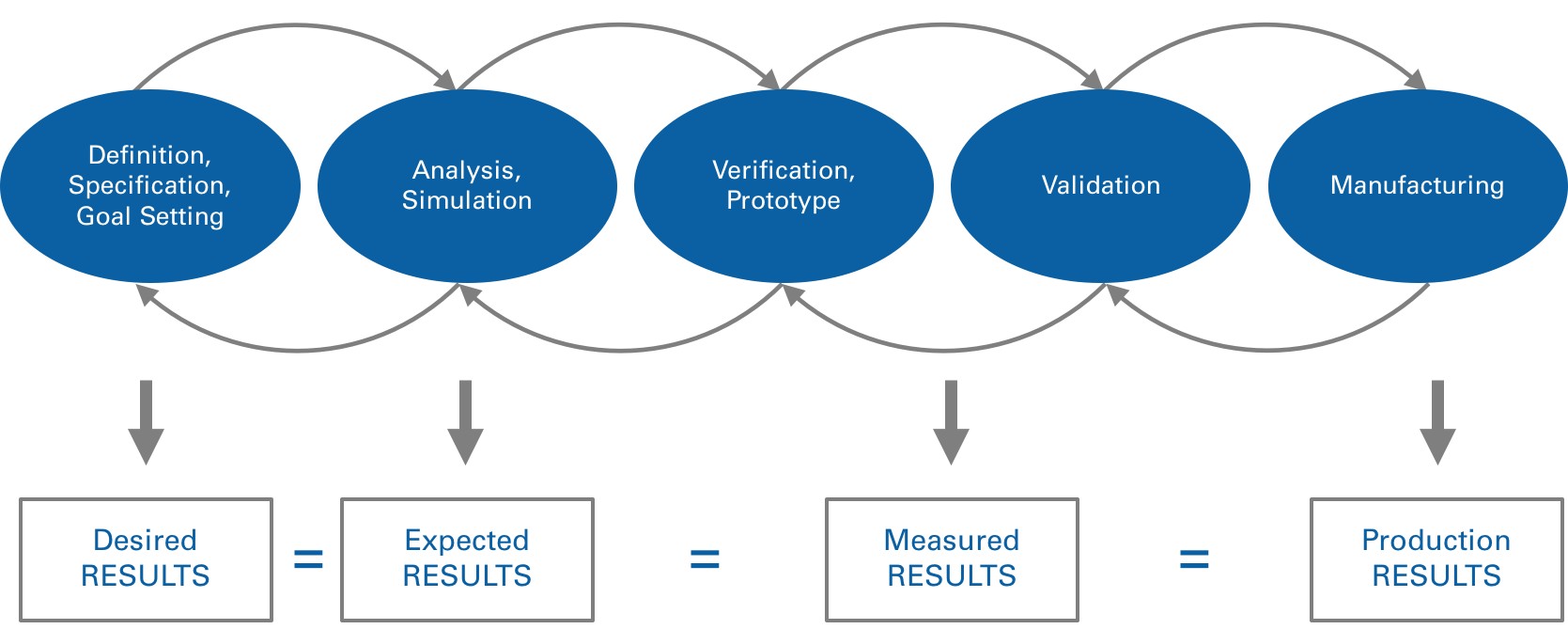

Design Flow to Ensure Quality

Figure 1 displays the hardware design flow at National Instruments. The key here is not only to go through the shown steps, but to make sure the results obtained in each step can be checked against previous steps. This check is important to be confident one can move ahead without ignoring possible issues. We compare all test results to expected behaviors to ensure the hardware functions as required and predicted.

Figure 1. NI hardware design flow

Supplier Proven

Our selected suppliers also take a demanding approach to building the devices we use in our products. For example, Xilinx offers military, industrial and automotive grade All Programmable SoCs and FPGAs. These are subject to additional testing and verification for temperature grade, performance and industry qualifications. Such devices often include IP from other vendors such as ARM that is used by 100s of other suppliers in 10,000s of products. This provides an inherent robustness that is leveraged and re-used by NI and our customers.

We work closely with our key suppliers which include Intel, Micron, Texas Instruments and Xilinx amongst others to ensure their product portfolios and roadmaps include the demanding requirements of NI and our customers. By selecting NI, you get the benefit of these strategic supplier relationships without having to manage these yourself.

Partner Proven

NI has a very large ecosystem of NI Partners who have built their business and reputation on NI products. We have over 1000 partners covering every region who themselves employ over 9,000 engineers themselves. These partners are experts on NI products in a large variety of industries and applications. NI requires a rigorous technical and business audit assessment to be classified in the various tiers of the program as well as specialty areas such as Electronic Design and Embedded Design. Additionally, various certifications are required, such as LabVIEW Certified Developer (CLD), LabVIEW Certified Architect (CLA) and LabVIEW Certified Embedded Developer (LVCED). Learn more about our NI Partner program.

Industry Proven

NI also leverages and re-uses other industry ecosystems. Some examples here are Linux Real-Time, Security-Enhanced Linux (SEL) and our support of the Linux Foundation (linux.org). Linux is developed and used by 10,000s of others providing higher levels of contribution and testing than proprietary offerings can offer. We also leverage the world’s most popular SW development IDE (Eclipse) and C/C++ compiler tool chain (gnu). These are all proven by their wide adoption and use for Intel and ARM ISAs.

Our platforms include IP from leading industry suppliers such as ARM, Intel and Xilinx. This IP is used by 1000s of other companies in 10,000s of products. This provides a level of quality and robustness that our customers and their customers can rely on and reduces risk.

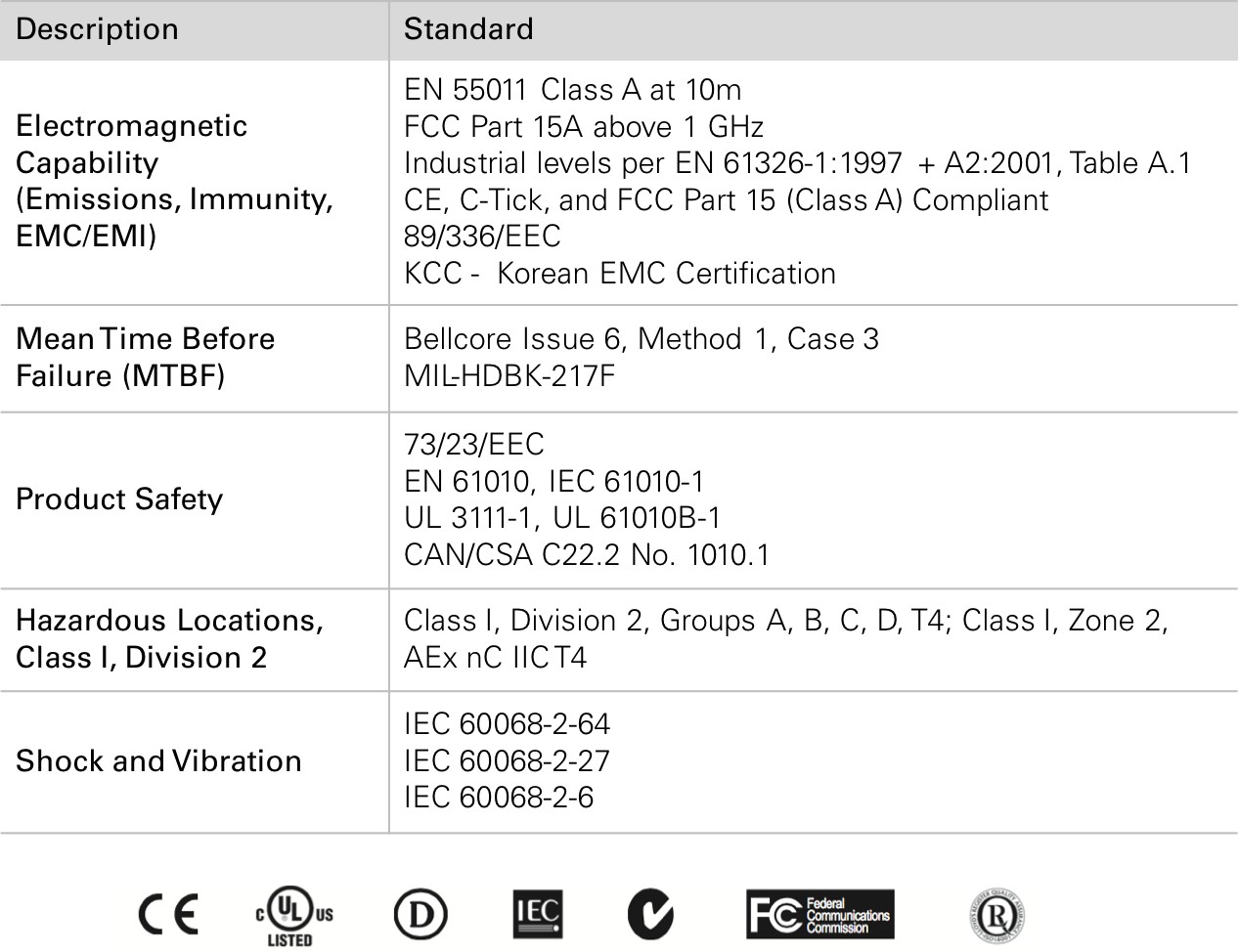

We also use industry standards to validate, qualify and certify our products. These are resource consuming, and can result in problems late in the design cycle causing expensive re-spins when required standards are not met. Our Compact RIO Controller products achieves the certifications as shown in Figure 2. Our Compact RIO Single-Board and SOM products cannot be certified for many of these since they are not packaged solutions, but they are tested and validated in-house at NI using the same validations. For example, we do the same shock and vibration on these-board-level products so that when you integrate them into your products, you can be confident that you have the best-in-class in the industry.

Figure 2. Best in class embedded system quality and ruggedness.

Customer Proven

NI products are deployed by 10,000s of customers underground, undersea, on ground, in the sky, on every continent, in every environment, on Earth. You do not achieve this without having the quality, reliability, robustness and ruggedness such requires. We have an extensive case study library available online where our customers discuss the benefits of using NI products from both the technical and business impact aspects. Customers use NI products for the most critical and demanding applications.

Every year, several thousand NI customers and partners converge at NI's annual user conference, now called NI Connect, to learn about, expand their knowledge and network with each other. NI Connect brings together the brightest minds in engineering and science. More than 3,000 innovators representing a wide spectrum of industries, from automotive and telecommunications to robotics and energy, will discover the latest technology to accelerate productivity for software-defined systems in test, measurement, and control. NI Connect is the ultimate learning environment that gives you the tools and knowledge to develop your applications faster, smarter, and more cost-efficiently.

The NI Community is an extensive and comprehensive network of world-wide user groups and discussions forums. 1,000s of NI customers are engaged to customers learn from and leverage each other’s capabilities and increase their expertise.

Core vs Context and Mission Criticality

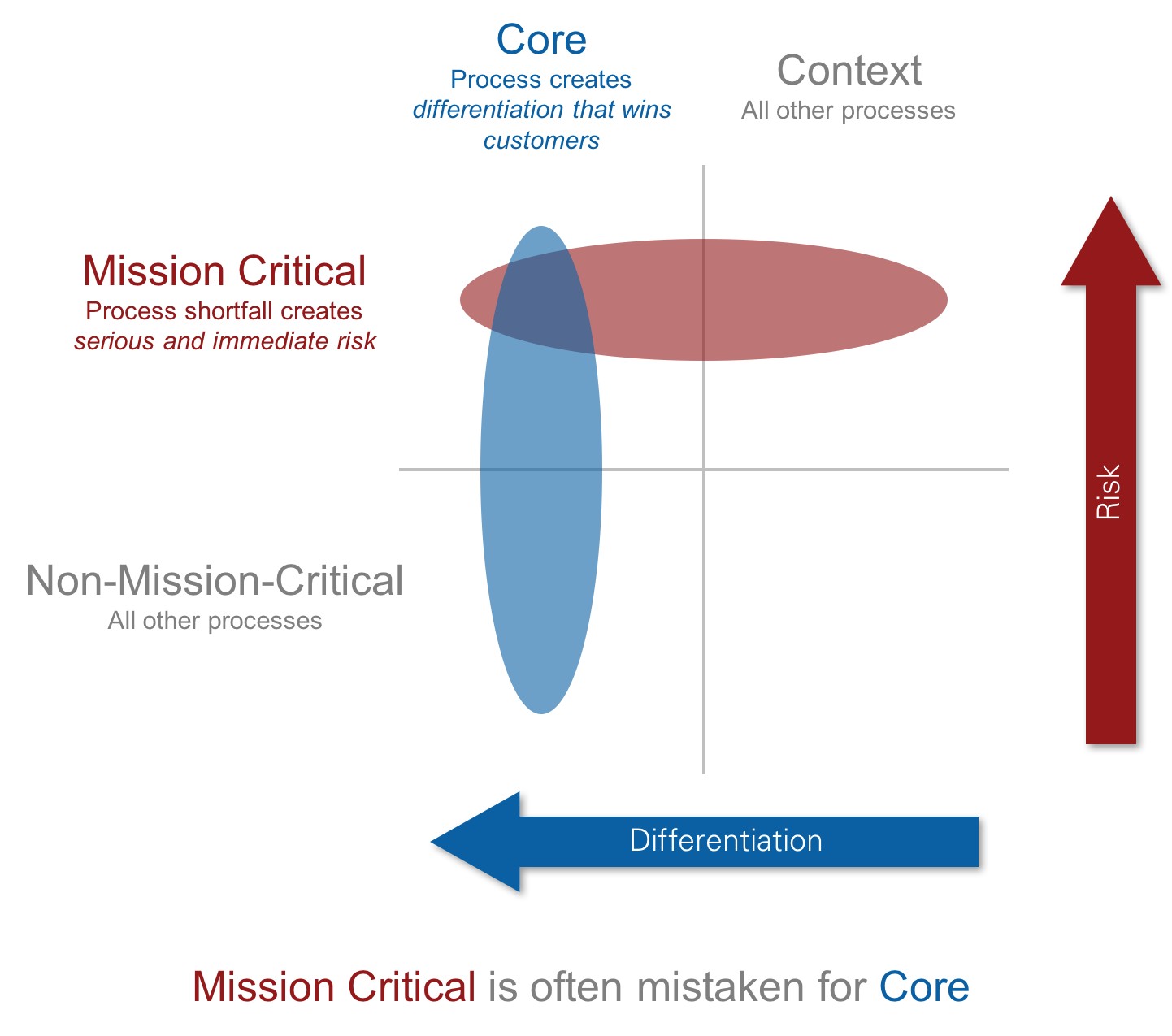

Many (if not most) companies are challenged with what they are developing and why. One of the roots of this is where should development resources be focused?

A core vs context analysis is one of the best tools for helping to determine this. Definitions of core and context:

Core:

- Innovation that creates differentiation leading to customer preference during purchase

- Combats commoditization and margin compression

Context:

- Everything else, not a source of differentiation

- What was once core becomes context over time, expected but not valued

- Can be a source of business and management inertia

“Core is what companies invest their time and resources in that their competitors do not. Core is what allows a business to make more money and/or more margin, and make people more attracted to a business than to its competitors. Core gives a business bargaining power: it is what customers want and cannot get from anyone else.” – Geoffrey Moore – author of Dealing with Darwin: How Great Companies Innovate at Every Phase of Their Evolution and Crossing the Chasm, etc.

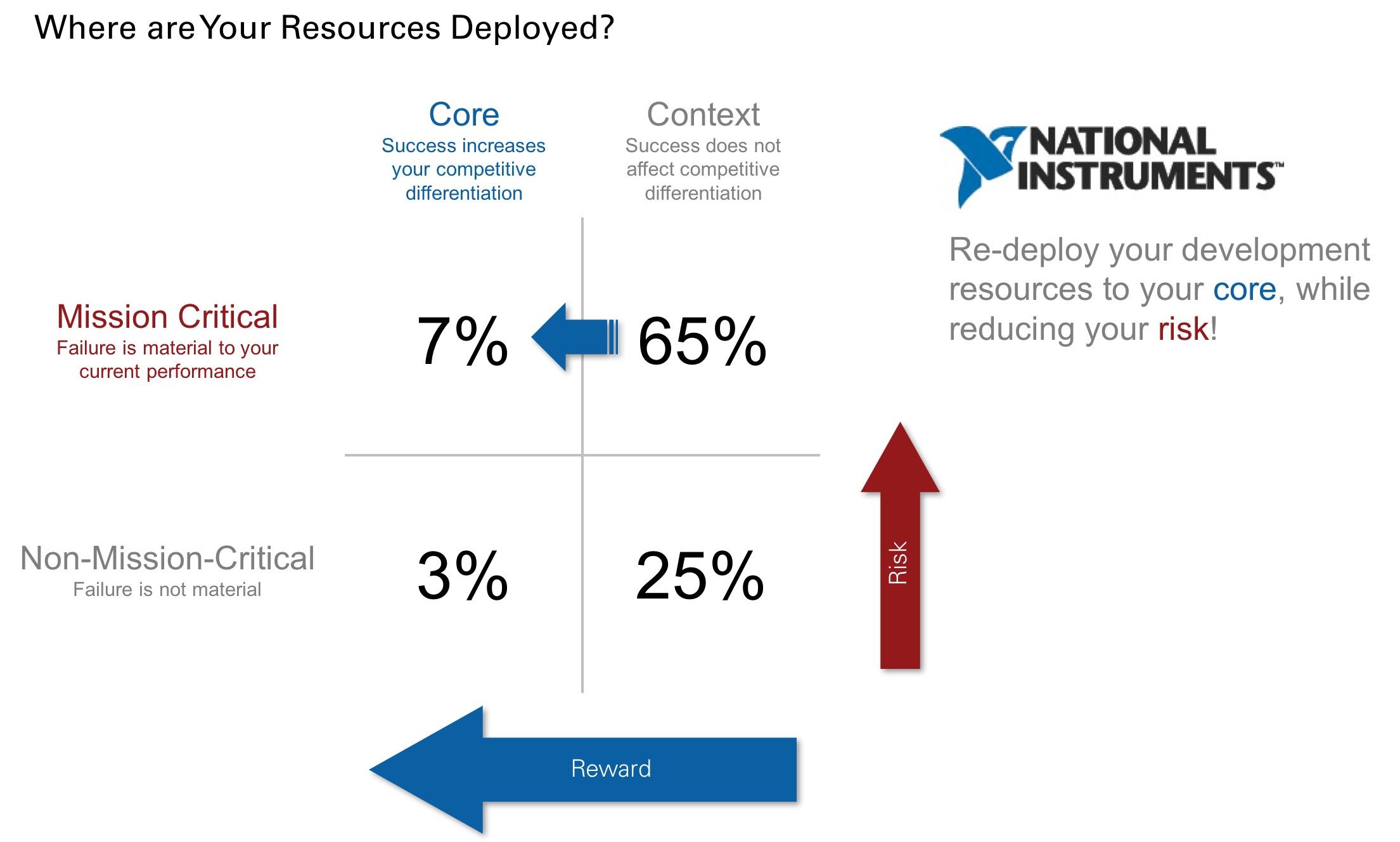

If we put these into a four-quadrant chart, we end up with what is displayed in Figure 3.

Figure 3. Core vs. context quadrants1

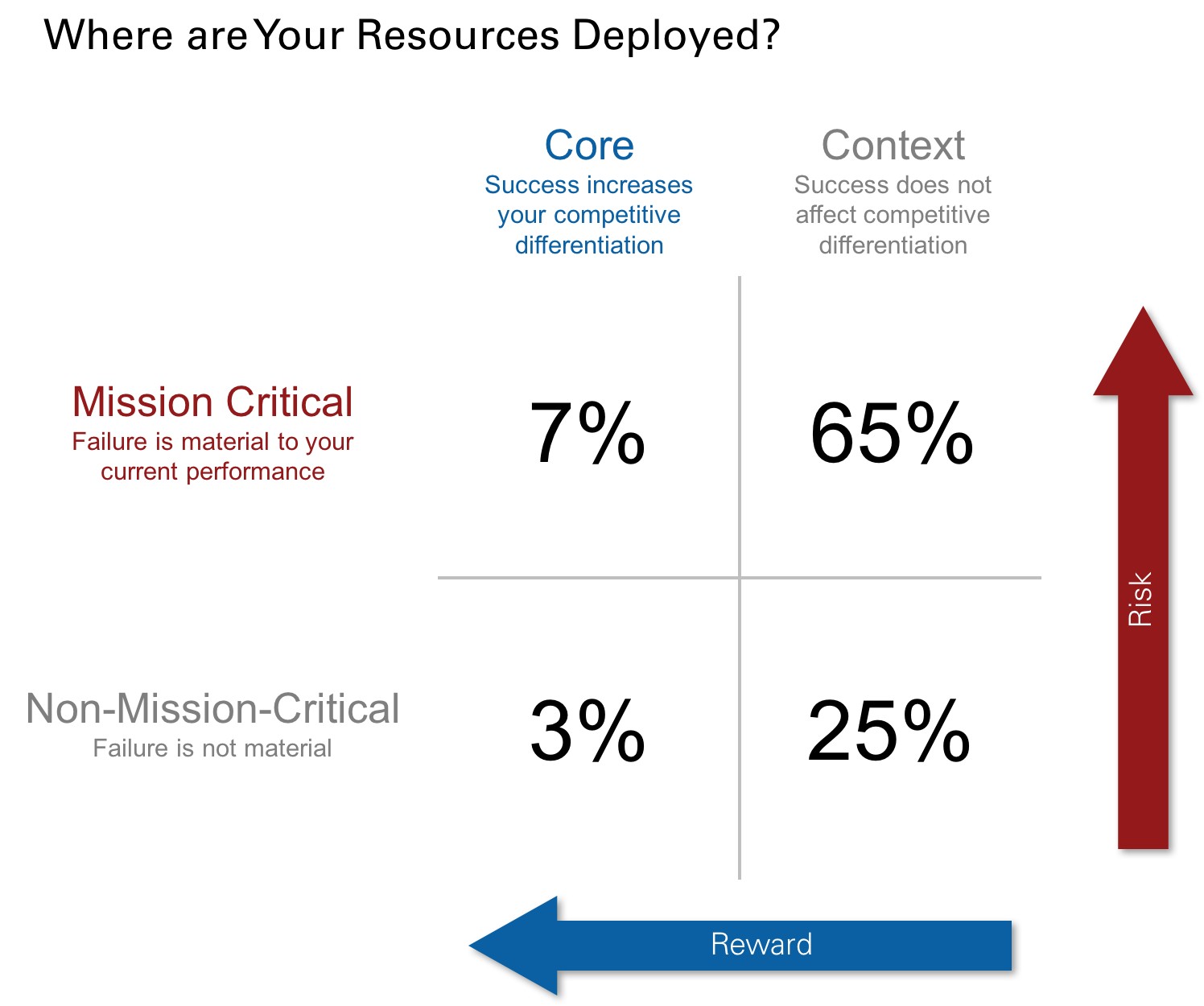

The real challenge is in the upper right, when something is critical, but is context, not core. Here is where the time needs to be spent understanding the nuances of core critical vs context critical and how best to address this. Why is this so important? Over time, most of the development effort and resources end up being “trapped” in the two context quadrants (65% + 25% = 90%) as shown in Figure 4. This is one of the primary root issues as to why it is so difficult to innovate and differentiate. The majority of the resources are spent doing context-critical but not core-critical work. Since it is critical and therefore risky, many businesses determine that this work must stay in-house.

Figure 4. Resources get trapped in context quadrants1

This creates a primary dilemma – how does one innovate/differentiate when up to 90% of the resources are trapped performing non innovative/differentiating work?

Why NI is Your Best Partner to Reduce Risk for Mission-Critical Solutions

One answer to this dilemma is to partner with a supplier such as NI for the context-critical control and I/O subsystem. As introduced in this paper, NI’s business is to provide the highest quality, most robust control and I/O subsystems. This, combined with our heritage in test and measurement makes us unique in the industry. Since this is core and critical to NI, you can be confident that we invest in and provide innovative, differentiating platforms for you to leverage. This frees-up your resources to be spent in what is core and critical for your business.

Figure 5. NI enables you to deploy resources back to core1

Test and Measurement Heritage

NI has a heritage rooted in test and measurement solutions. Many leading companies use NI products to simulate, test and validate their products spanning the conceptual to production continuum. They rely on NI to ensure that their products met exacting standards of quality, performance, precision, timeliness, etc. We take this responsibility seriously and that is why we use such rigor in our own design, verification, validation and production processes. When you use NI as a supplier, you are often using the same platforms which were used to design, test and validate many of the other products you use in your own processes. Test and measurement is core and fundamental at NI and not simply just a check box process. When choosing NI, you reduce risk rather than increase the risk you take on by doing your own control and I/O subsystems or selecting another supplier who has fewer vectors of proven. You also free up resources to do more core-critical work resulting in more competitive products that meet your customers’ needs, a double win for you.

When selecting a supplier for your critical control and I/O subsystems, do the due diligence to understand what you are truly getting. Is their design, test, validation and production as least as complete and comprehensive as your own? Does the supplier truly understand how critical these subsystems are and have they appropriately invested into all the right tools, expertise and their own supplier relationships? Do they have a world-wide ecosystem of committed partners and customers whose own efforts have proven the test of time? Do they have documented evidence of a proven history covering the five domains of company, supplier, partner, industry/ecosystem, and customer for you to trust what is critical to your business success? At NI we are proud of what we build and accept what it means to be a trusted supplier.

Next Steps

1Moore, Geoffrey. Dealing with Darwin. N.p.: TCG Advisors, 11 Aug. 2010.

The registered trademark Linux® is used pursuant to a sublicense from LMI, the exclusive licensee of Linus Torvalds, the owner of the mark on a worldwide basis.

An NI Partner is a business entity independent from NI and has no agency, partnership, or joint-venture relationship with NI.