Test is Transforming the Auto Industry

BUSINESS INSIGHT

TRANSPORTATION | 4 MINUTE READ

CES 2023 proved that test and software will be key to delivering the next generation of software-defined vehicles.

Every year, professionals from all over the world flock to Las Vegas for the Consumer Electronics Show (CES)—one of the most influential trade shows in the world, spotlighting breakthrough, next-gen technologies.

The 2023 CES automotive hall had no shortage of glitzy automotive innovations to enjoy. Sony introduced its first concept car, the Honda AFEELA, with 45 sensors to support ADAS/AD capabilities, telematics, and connectivity. BMW debuted the i Vision Dee, a new concept car with a color-changing exterior of up to 32 hues.

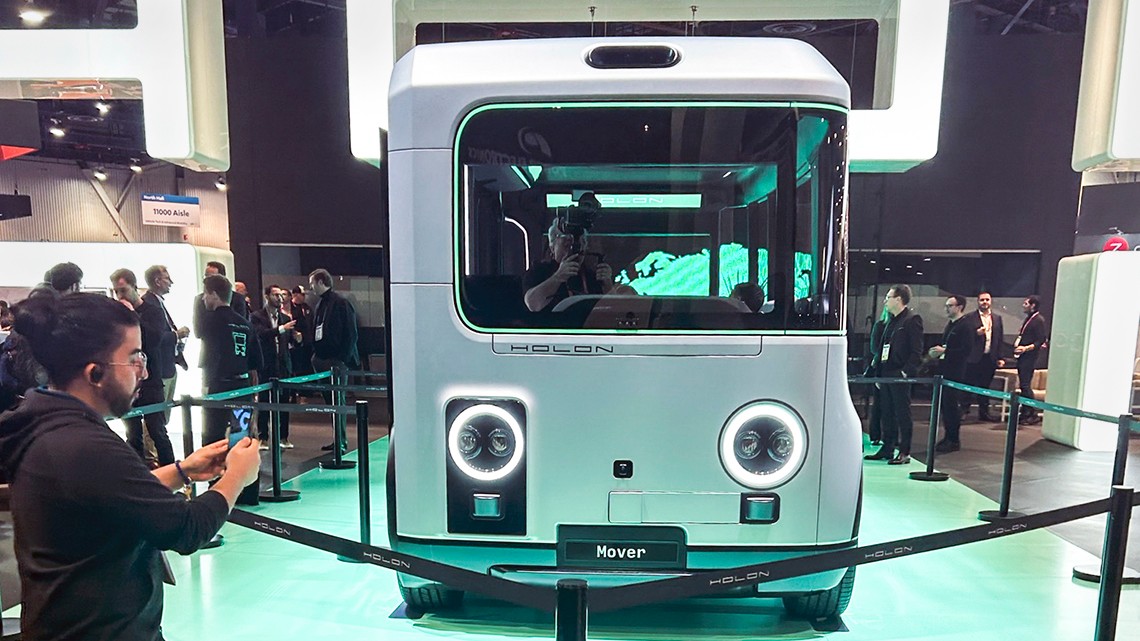

This year, we noticed something remarkedly different about CES’ offerings. Aside from a host of futuristic concept cars, compared to previous years, industry giants tended to feature electric and autonomous vehicle technologies that are readily available now or could be in our businesses, communities, and “connected” homes in a matter of months. Even just a few years ago, autonomous mobility was seen, in many ways, as a sci-fi fantasy where cars fly and upend our lives. CES 2023 has proved that EV and ADAS have moved to the realm of “inevitable technology path.” So, how exactly has test made this automotive evolution a reality?

CES this year underscored an inflection point in the industry: Automakers are reevaluating their approaches and leaning on software and data-driven test to deliver the safest, most reliable products to market. The prominence of test technology was more apparent than ever at the show. No longer an unsung hero fighting for visibility, test was in full view in some notable ways.

At CES, not only were top test and measurement providers present, demonstrating their latest technologies, our customers were proudly showing how—and why—they’re including test in their workflows. Simply put, autonomous vehicular features are increasingly common and becoming mainstream, in part because the technology required to produce these advances is readily available and can be integrated in real-world applications. Car manufacturers, for example, can now push the limits of battery range, infotainment systems, and lidar technology. Meanwhile, the market grows more comfortable, even eager, about what’s next with assurance from the industry that the number of unknowns around electric and autonomous vehicles is being reduced with rigorous test and data.

As vehicles become more complex, with components like sensors and cameras, robust testing infrastructure is needed to validate safety critical subsystems and overall vehicle performance. Essentially, vehicles need to be as savvy as our smartphones yet as safe as an airplane since failure isn’t an option—as demonstrated by the industry-wide goal of VisionZero (zero emissions, zero accidents, and zero congestion). To scale innovation and keep pace with competition, more and more manufacturers see test as key to their success.

At NI, we believe software is what will enable us to speed innovation and test cycles compared to legacy techniques. CES 2023 only strengthened our beliefs and highlighted how vehicle software management is the next frontier. It can be challenging for one company to maintain an entire toolchain alone—combining strengths with other experts can give you the competitive advantage. From semiconductor architectures to new partnerships and products, developing end-to-end infrastructure to serve software-defined vehicles will be a focus and challenge across our industry. At CES, Amazon, Microsoft, Aptiv, Marelli, Bosch, and other companies demonstrated their DevOps tools for deploying and testing embedded software, and many were talking about hardware-in-the loop.

NI is at the forefront of test solutions for the transportation industry. Our software-defined test tools have helped our automotive customers evolve and integrate their complex systems with analytical tools to draw valuable insights from their data. Our hardware-in-the-loop test systems increase coverage and shorten test time by moving the bulk of testing from the road to the lab through simulation. Especially when tasked with testing against infinite scenarios, NI’s connected ADAS and AD workflow and data management solutions enable you to validate sensor and software performance of the entire vehicle more efficiently.

Make no mistake, a number of obstacles stand in the way of full EV/ADAS implementation, such as sourcing raw materials for vehicle components, deploying adequate charging infrastructure, and avoiding negative climate and environmental impacts. The practical designs exhibited at CES this year are an inspiring reminder that the industry is joining forces to alleviate some of these problems.

We see the roadblocks, too, and are helping customers across every sector Engineer Ambitiously and deliver the best real-world solutions to transportation. NI is partnering with best-in-class automotive leaders to create a more sustainable future for mobility.