Why choose NI for PMUs and Wide Area Monitoring

Overview

Power management units (PMUs) have helped foster high speed data gathering from the grid with some utilities capturing phasor data as fast as 1 sample per cycle. As adoption and experience with PMU data grows, new possibilities emerge to help better monitor and control the dynamic health of a utility grid. PMUs built on NI technology have several advantageous features that can help utilities, power systems engineers, and grid researchers better understand the health of the grid. This paper covers four specific benefits of NI technology for PMUs and wide area monitoring systems.

Contents

- A Platform Based Approach

- Customized Utility Protocol Selection

- LabVIEW Software for Grid Deployments

- Processing Power at the Grid Edge

- Conclusion

- Additional Resources

A Platform Based Approach

It is important to consider change as one of the challenges that is impacting the grid today. Loads are changing as more plug-in electric vehicles and home storage systems continue to enter and grow in the market. Generation is changing with the growth of distributed renewables, most all of which run through inverters. Computer based instrumentation technology is changing as well. With the advent of industrial Internet of Things (IoT) technologies comes the promise of improved operations with lower operational costs. Managing these changes and new technologies requires an equipment strategy that can keep up without requiring large expenses as new breakthroughs are made. NI technologies are all platform based and designed to follow the commercial technology curve with less impact to development and management costs. The NI platform approach abstracts the low level middle-ware required when designing embedded I/O systems and helps the domain expert focus on the challenge at hand. As an example, LabVIEW code that was developed for the original CompactRIO controller (195 MHz Power PC processor), can be ported to one of the latest CompactRIO controllers (dual/quad core INTEL ATOM), with significantly less effort than traditional design methods. In a specific example, NI customer Prolucid was able to port their microgrid communication code from the cRIO-9076 controller to the newer dual core ARM9 processor based cRIO-9068 in less than a day calendar time.

"Prolucid started using the NI cRIO-9076 controller based on a VxWorks real-time OS; however, the application was also ported to the cRIO-9068, which immediately delivered several additional benefits, including increased processor performance, a larger FPGA, access to an open real-time OS ecosystem, and improved ruggedness.

Within 24 hours of receiving the first cRIO-9068, Prolucid engineers were able to port their LabVIEW application from the cRIO-9076 and see increased processor performance. In benchmarking, the 400 MHz single-core processor of the cRIO-9076 successfully ran the application at 70 percent CPU utilization. But engineers saw a 4X performance increase with the cRIO-9068 processor running the exact same LabVIEW code, which had a combined CPU utilization of 17 percent. Along with the improved processor performance, more processing algorithms were able to fit within a larger FPGA fabric."

|  |

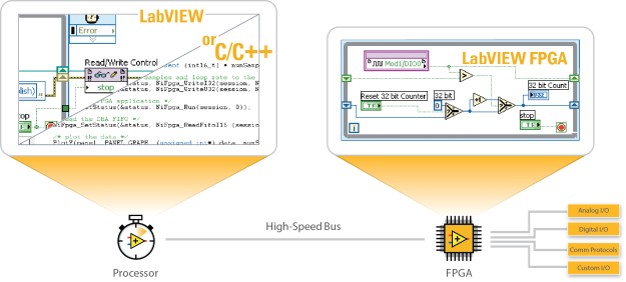

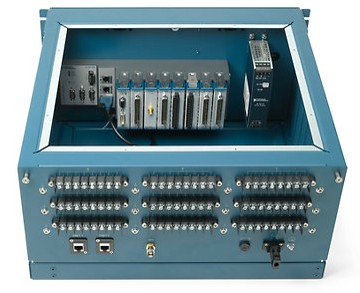

Figure 1: NI hardware and software for platform based design help grid experts build custom devices that keep up with the evolving problems facing the grid today.

Customized Utility Protocol Selection

Integrating systems from different vendors or those that use different standards often involves intermediate software running on a separate controller to translate across system boundaries. NI controllers have programmable access to the hardware communication ports and several software based protocol toolkits available through LabVIEW. The core controller of NI PMUs can have up to 2x ENET ports, 2x RS-232 serial ports, and 1x RS-485 ports. This means that a single system could communicate using the IEEE C37.118.2 protocol over one ENET port, IEC 61850-GOOSE over the another, DNP3 from one of the serial ports and MODBUS from the other. This flexibility helps integrate PMUs built on NI technology into existing systems without having to completely overhaul data management and communication schemes.

Some utility focused protocols available include:

- DNP3

- IEEE C37.118.2

- IEC 61850 (MMS, GOOSE, and SMV)

- IEC 60870-5

- Modbus over Ethernet and RS-232

- Serial

LabVIEW Software for Grid Deployments

Software is an important part of the advantage when looking at NI technology for grid deployments. LabVIEW and the Electrical Power Toolkit include thousands of pre-built processing and analysis functions including statistical math, polynomial interpolation, waveform processing, and a full range of power measurement and quality functions. Domain experts working with LabVIEW can use these building blocks to design their solution and get to simulation or pilot faster than the traditional method of working with research labs and vendors that would need to go through a design process for a new instrument.

Processing Power at the Grid Edge

As grid measurement and control grows in software complexity it is important to have enough processing power installed in the right locations to enable eloquent, robust systems. Every CompactRIO controller has a combination of a core processor and an FPGA, both of which are programmable using the LabVIEW development environment.

Figure 2: The LabVIEW RIO architecture combines a processor, FPGA, and I/O elements. These hardware elements, combined with LabVIEW development software, are building blocks for embedded systems that help design measurement and control devices in less time than traditional methods and empower domain experts to create their own solutions rather than relying on a team of embedded developers.

Core Processor

The core processors available range from dual core ARM9s clocked at 667 Mhz/core to a quad-core INTEL processor clocked at 1.91 GHz/core. The core processor typically handles system functions such as file I/O, disk management, web services, protocol communication, and freely programmable computational algorithms. As a benchmark, the cRIO-9068 controller running the shipping version of the Open PMU Project for LabVIEW uses less than 25% of the core processors resources to run the PMU algorithm for 2x 3-phase busses.

FPGA

The FPGA has multiple functions for utility applications. It is often used as a co-processing element to handle intensive in-line signal processing performed on sampled waveforms from the ADCs. Common signal processing for 50/60 Hz systems includes zero-cross detection, resampling of the waveform to constant phase angle, and filtering for enhanced zero-cross detection or other specific algorithms.

Other functions of the FPGA include synchronous time stamping from a GPS clock to an ADC sample point for synchrophasor measurements, and high speed input/output control for relay applications.

Why FPGAs?

There are multiple silicon level technologies, such as FPGAs, DSPs, and ASICs, that are used today in utility grid applications for synchronization and co-processing. FPGAs bring some distinct benefits to the NI technology platform that are critical to helping with future utility equipment strategies.

- The firmware of an FPGA can be changed once the controller is deployed in the field. This is critical as the processing algorithms may need to change to better capture different power quality phenomena in the future. Years of algorithm research can be applied to the field with a software upgrade rather than a new equipment purchase. ASICs by contrast, are very cost effective in ultra-high volumes but the technology is locked at the time of manufacturing which can lead to stale instrumentation once standards change or new problems emerge.

- FPGA technology has evolved to blend multiple processing elements into a single die. FPGAs of today come with logic fabric, DSP slices, and some even contain processing cores. This flexibility makes them an ideal fit for platform based designs as platforms need to serve a variety of applications with fewer, more abstract design elements.

Traditionally, FPGA design involves special, low level design tools and years of school work to establish proficiency. NI products with an FPGA, such as CompactRIO, are programmed with LabVIEW and require less effort to establish a working knowlege.

Conclusion

The grid in general, but PMU based instrumentation specifically, is evolving rapidly. A platform strategy for instrumentation is needed to augment the existing fixed functionality devices that are on the market. NI tool and technology help power systems engineers and utility experts create custom PMU based instruments that are flexible enough to keep up with grid and technology changes.

Additional Resources

- Learn about NI technology use in other utility applications

- Read a white paper on How to Measure Current, Voltage, and Power with NI Technology

- Learn more about the LabVIEW Electrical Power Toolkit