NI PXI and LabVIEW Deliver Unrivaled Performance, Flexibility, and Value for Automated Test

Overview

Automated test engineers need to develop innovative test systems to meet challenging time-to-market and performance requirements. The combination of PXI and NI LabVIEW system design software represents a complete automated test platform that empowers you to build virtually any system faster and with more confidence. LabVIEW helps you stay ahead of demanding system needs by providing integration with a wide variety of instruments, ranging from traditional boxes to software-defined PXI modular instruments, allowing nearly any measurement to be acquired. Additionally, you can use LabVIEW to take advantage of technologies such as multicore processors and field-programmable gate arrays (FPGAs), which can help you build more advanced test systems faster.

Contents

- Reduce Test Development Time With Intuitive Graphical Programming

- Simplify System Integration With a Single Software Environment

- Reduce Execution Time and System Cost With Commercial Off-the-Shelf Technology

- Accelerate Your Productivity—Analyze Signals With Built-In Math and Signal Processing Functions

- Display Results With Custom User Interfaces

- Take Advantage of a Complete Platform for Automated Test

- Explore Customers Successes With This Automated Test Platform

- Learn More

Reduce Test Development Time With Intuitive Graphical Programming

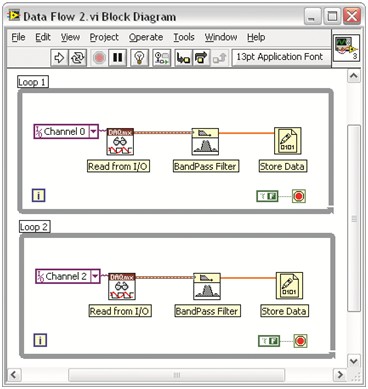

LabVIEW features an intuitive graphical programming environment that helps you quickly develop test applications. Graphical programming uses “icons” or symbolic functions that pictorially represent the action to be performed. These symbols are connected through “wires” that pass data and determine order of execution similar to a flowchart, which is then compiled into machine code so the computer processor can execute it. LabVIEW, although syntactically different, contains the same programming concepts found in most traditional languages. LabVIEW executes according to the rules of data flow instead of a procedural approach, found in languages such as ANSI C and C++, in which a sequential series of commands are carried out. The LabVIEW dataflow approach reduces system development time by offering a more intuitive user experience and providing a clear understanding of how steps are executed and how data moves throughout the application.

Figure 1: The movement of data through the nodes determines the execution order of the VIs and functions on the block diagram.

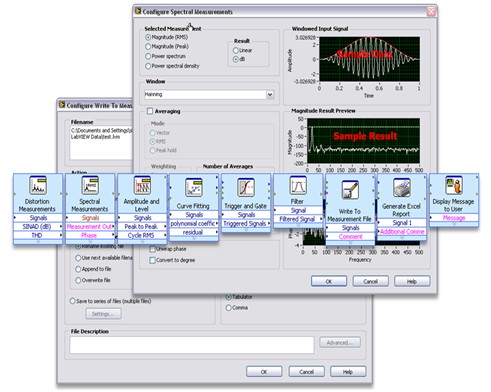

LabVIEW provides a variety of programming approaches to help you build test systems, regardless of your domain expertise. An example of measurement abstraction with LabVIEW is through Express VIs, which abstract tasks by offering a configuration-based approach to programming. When an Express VI is used, an interactive dialog helps walk the user through configuration options and details for how the function executes. LabVIEW automatically takes care of the back-end code required to execute the function configured in the Express VI with no additional programming required by the user.

Figure 2: LabVIEW provides a variety of analysis and instrument control Express VIs that you can use to simplify development of a test application.

Debugging source code is an important part of the development process. LabVIEW provides powerful debugging tools that you can use to watch, pause, and evaluate data as it moves through the LabVIEW program. LabVIEW also helps you detect and resolve errors earlier in the development cycle by providing live error checking and visual representations of semantic and syntactic issues within the source code. The combination of graphical code and sophisticated debugging tools help you to complete test applications in less time than with traditional languages, even with minimal programming experience.

Simplify System Integration With a Single Software Environment

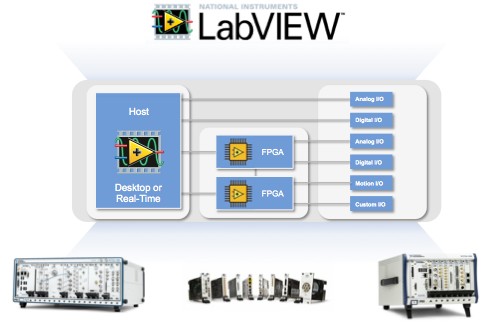

As device complexity increases, test systems must respond with more flexibility. Using LabVIEW and PXI software-defined modular instruments, you can take advantage of multivendor open standards to design and implement flexible test systems that can be repurposed quickly. As systems use a variety of instrumentation, integrating all capabilities and programming approaches can be challenging. With LabVIEW, the integration process is easier and often eliminates steps, saving time and frustration.

With LabVIEW, you save time and money by automating all of the test instrumentation from a single development environment. LabVIEW driver software supplies seamless integration across multiple types of instruments, buses, and sensors, everything from boxed instrumentation to FPGAs, allowing you to integrate nearly any instrument into your test system. Driver software is readily available and offers convenient access to all of the functionality of the hardware. LabVIEW drivers install directly into the programming Functions Palette so time is not wasted locating and including support for the hardware.

Figure 3: Customize an application to fit evolving requirements through a wide range of instrumentation and a single software tool to accelerate productivity when building automated systems.

With the modular, software-defined configuration of PXI, you can create customized testing solutions for evolving system requirements and needs. With connectivity to more than 1,500 PXI products, LabVIEW is the best way to incorporate PXI into a test system.

Reduce Execution Time and System Cost With Commercial Off-the-Shelf Technology

The test industry is continuously evolving to take advantage of the latest developments in commercial off-the-shelf technology, such as multicore processors and FPGAs, to help you achieve shorter test times and meet the performance requirements of the latest applications. Pairing PXI with LabVIEW improves test systems performance by programming multicore processors and other parallel hardware such as FPGAs with no additional programming effort. LabVIEW helps you visualize and implement parallel operations because it naturally represents the most popular parallel programming patterns and makes it simple to automatically scale test applications to CPUs with multiple cores.

Figure 4: With LabVIEW, you can take advantage of this powerful technology using a platform that evolves quickly to adopt the latest commercial off-the-shelf technology.

With LabVIEW and NI PXI embedded controllers, based on the latest multicore processors, test applications can distribute their processing loads across the available CPU cores instead of having a dedicated tester for every device under test (DUT). Using LabVIEW to allocate hardware resources and measurement routines across multiple cores helps you to run multiple tests in parallel, therefore improving productivity and throughput.

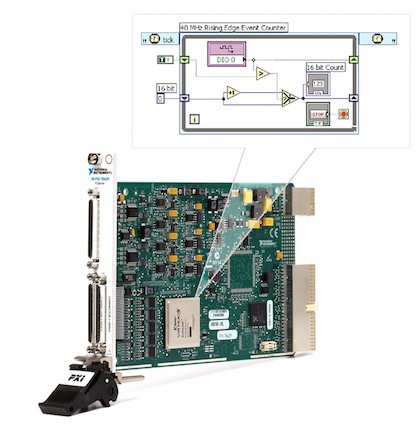

In addition to multicore CPUs, LabVIEW also delivers FPGA capability to test systems. FPGAs present a powerful solution for applications that require the ultimate in flexibility, reliability, and customization. Although FPGAs have unique characteristics, advantages, and trade-offs, LabVIEW empowers you to directly incorporate custom signal processing and control algorithms into FPGAs on measurement hardware.

Figure 5: With the NI LabVIEW FPGA Module, you can use familiar LabVIEW code to customize your PXI instrumentation.

LabVIEW is well suited for FPGA programming because it clearly represents parallelism and data flow, so engineers who are both experienced and inexperienced in traditional FPGA design can productively apply the power of reconfigurable hardware. With open, customizable I/O, FPGAs provide the flexibility to meet the exact requirements of a test system.

Accelerate Your Productivity—Analyze Signals With Built-In Math and Signal Processing Functions

LabVIEW features thousands of built-in, engineering-specific software libraries enabling easy acquisition, analysis, control, and data sharing. With LabVIEW, you gain access to more than 850 built-in signal processing, analysis, and mathematics functions that simplify test system development. These analysis functions provide the freedom to choose how to implement analysis into the test application, both inline and offline, allowing you to fully customize the test system algorithms, make intelligent measurements, and obtain results faster.

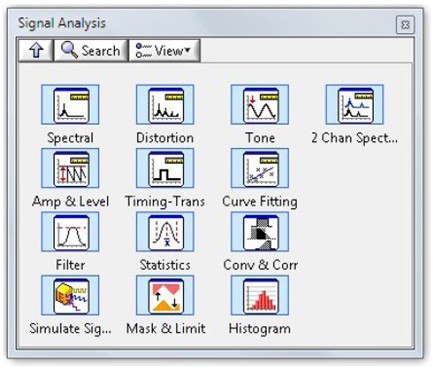

Figure 6: Take advantage of the many built-in functions to reduce the complexity associated with adding analysis and signal-processing algorithms to an application.

Due to the diversity of test application requirements, the built-in analysis and signal processing functions range from high-level, configuration-based assistants to low-level building blocks that you can combine to fully customize test routines. Configuration-based Express VIs are the simplest way to add inline measurement analysis and signal processing to a LabVIEW application. For engineers who want low-level building blocks, LabVIEW contains functions ranging from filtering, signal generation, and waveform measurements to differential equations, curve fitting, and statistics. Although LabVIEW is well known as a graphical programming environment, it also offers math-oriented textual programming. You can use MATLAB Script nodes to make ActiveX calls to MATLAB software installed on the same machine to execute scripts. With this wide range of easily accessible functionality, an automated test platform built on PXI and LabVIEW provides the unrivaled flexibility for any application need.

Display Results With Custom User Interfaces

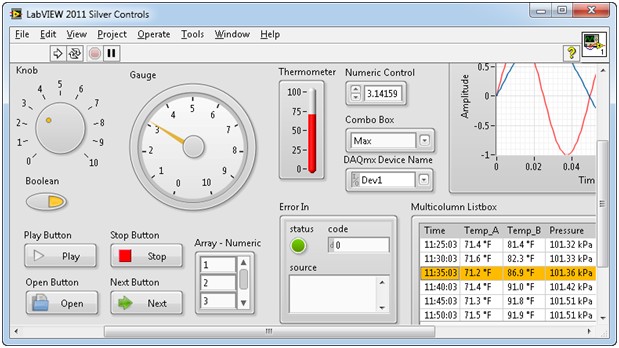

With LabVIEW, you get more than just acquisition and analysis—you can create custom user interfaces that display measurement-specific data and test results within the same environment. LabVIEW contains a comprehensive collection of test-specific drag-and-drop controls and indicators so you can quickly and easily create user interfaces for the application and effectively visualize results.

Figure 7: Choose from a variety of engineering-focused controls and indicators to create a custom interface.

LabVIEW gives you full control over what is visible and can protect pieces of the user interface that should not be changed by an operator. You can customize the format and appearance of these built-in controls in a matter of seconds, resulting in a clear application that can be easily used and understood. Within LabVIEW, choose from a variety of customizable control themes ranging from appearing as a Windows application to changing all controls and color scheme to suit a specific company brand.

Figure 8: Combine all of the most important information from a test system into an application-specific GUI using LabVIEW for engineers or test system operators.

Pairing LabVIEW data visualization and user interface capabilities gives you the tools to quickly display data and provide intuitive ways to interact with your system. Built-in controls work seamlessly with acquired data so no time is wasted converting and massaging data into new formats purely for display. For test applications that require a more specific view, LabVIEW is customizable and extensible—which means you can define appearance and behaviors resulting in data being shown in a way the user would best understand it.

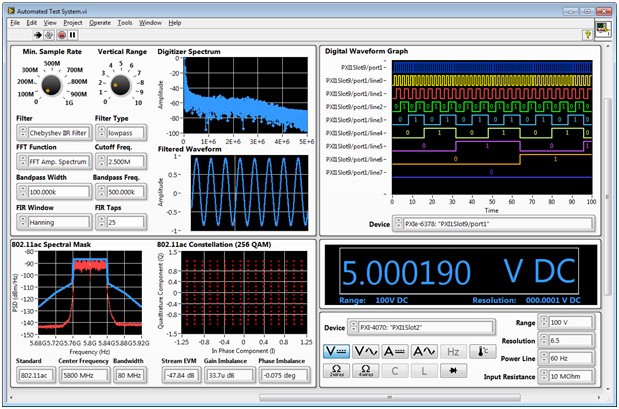

Take Advantage of a Complete Platform for Automated Test

Together PXI and LabVIEW, a complete platform for automated test, give you the ability to develop solutions for increasingly complicated test systems. LabVIEW provides an intuitive graphical programming approach that reduces test development time through the drag-and-drop graphical icons instead of writing lines of code. By taking advantage of a wide variety of PXI instrumentation and platform products, including the latest technologies such as multicore and FPGAs, LabVIEW is a single software environment that simplifies integration and reduces execution time. LabVIEW accelerates your productivity by using a wide array of built-in math and processing functions and focusing on the data and results. Lastly, when displaying results in LabVIEW, you use built-in engineering-specific controls and indicators to customize user interfaces. The combination of PXI and LabVIEW system design software empowers you to build virtually any automated test system faster and with more confidence.