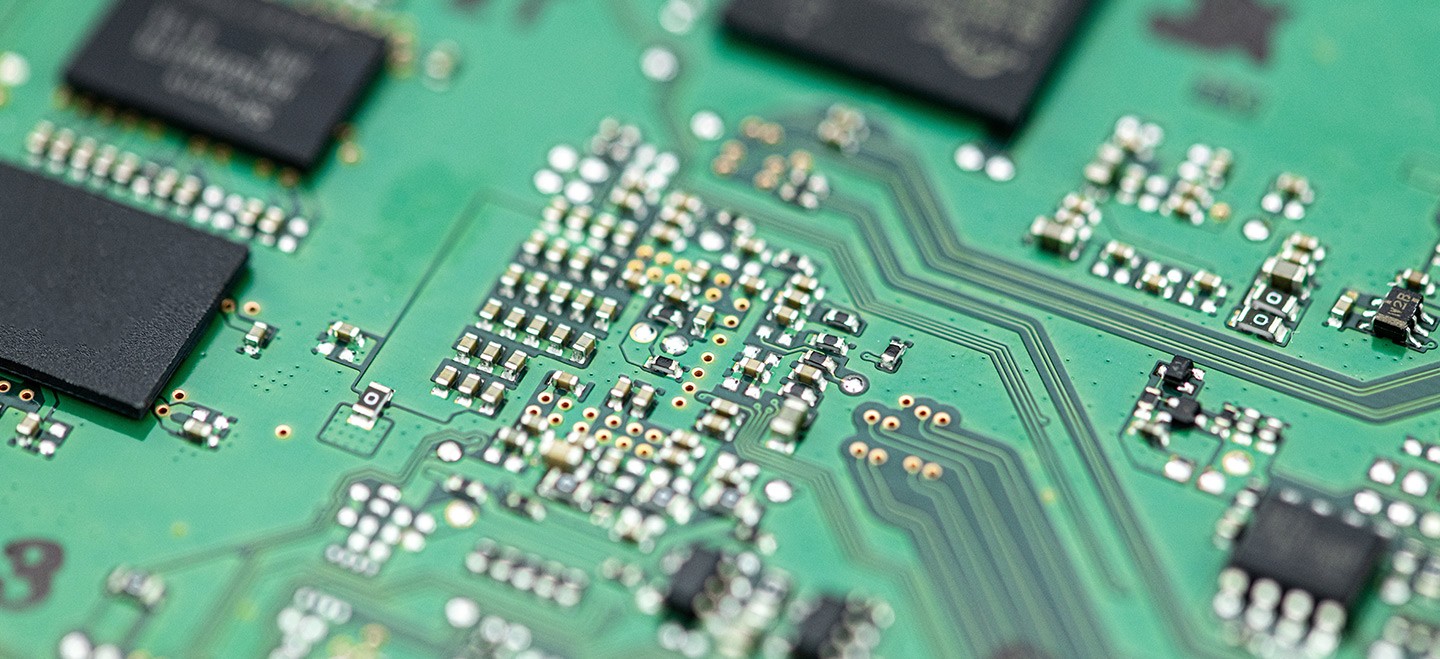

NI offers streamlined PCBA functional test solutions with key differences:

- Modular and flexible—Use NI tools to adapt to challenges and stay on schedule.

- Standardization—Lower cost of test by sharing code libraries and hardware architectures among test teams.

- High-quality instruments—Our reliable test systems produce consistent results over time.

- Software defined—NI’s software helps engineers along the entire workflow of test, enable faster and more efficient tests, while maximizing your test data.