PXI Express DMMs Form Foundation for More Accurate, Smarter Test Systems

Overview

Increasing device complexity and continual economic pressure have driven engineers to automation as a cost-effective way to deliver repeatable results throughout the design cycle: characterization, verification and validation, and production test. In today’s market, a digital multimeter (DMM) often needs to provide more than just accurate and precise measurements. The design and test engineers who automate DMM measurements need an accurate and precise DMM that reduces measurement time, integrates seamlessly with other instruments, and offers easy channel expansion through switching. You can best meet these needs with a modular platform that provides excellent measurement quality and fast results in a form factor optimized for automation.

Contents

- Built for Automated Test

- NI’s Software Advantage

- High-Precision DMM Measurements

- Flexible Measurement Rate With an Isolated Digitizer

- Self-Calibration and 2-Year Guaranteed Specifications

- Synchronization and Integration

- Build Your Next Test and Measurement System With NI DMMs

- Next Steps

Built for Automated Test

NI’s PXI-based DMMs range from low-cost 6½-digit devices to high-performance 7½-digit models, including the most accurate 7½-digit DMM on the market. Some models include specialized features such as extended measurement ranges, an isolated digitizer mode with sample rates up to 1.8 MS/s, extended calibration cycles, and basic inductance and capacitance measurements. Combined in a single instrument, these features provide a solution to the measurement challenges inherent in traditional precision instruments: limited measurement throughput and flexibility. These DMMs deliver a smarter way to tackle difficult applications in industries ranging from consumer electronics to aerospace and defense.

Figure 1: The PXIe-4081 DMM is a zero-compromise solution for any test and measurement system.

Resolution (digits) | 6½ | 6½ | 7½ | 6½ |

Maximum Voltage (V) | 300 | 300 | 1,000 | 300 |

Maximum Current (A) | 3 | 1 | 3 | 1 |

Maximum Sample Rate | 3 kS/s | 1.8 MS/s | 1.8 MS/s | 1.8 MS/s |

Voltage Accuracy (10 VDC, 2-year) | *90 + 12 ppm | 25 + 6 ppm | 12 + 0.5 ppm | 25 + 6 ppm |

Maximum Calibration Cycle | 1-year | 2-year | 2-year | 2-year |

DC and AC Voltage | ✓ | ✓ | ✓ | ✓ |

DC and AC Current | ✓ | ✓ | ✓ | ✓ |

2-Wire and 4-Wire Resistance | ✓ | ✓ | ✓ | ✓ |

Frequency/Period |

| ✓ | ✓ | ✓ |

Basic Inductance/Capacitance |

|

|

| ✓ |

*The PXI-4065 doesn’t offer a 2-year specification, so the 1-year specification is shown. | ||||

Table 1: NI offers DMMs ranging from low-cost 6½-digit options to the most accurate 7½-digit DMM on the market.

Figure 2: NI’s PXI-based DMMs provide a solution to the measurement challenges inherent in traditional precision instruments: limited measurement throughput and flexibility.

NI’s Software Advantage

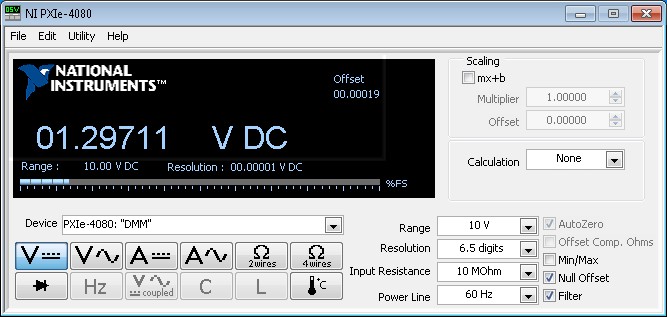

Because NI DMMs are designed for automated test applications, you use software to control and communicate with the instrument. For quick measurements or application debugging, the DMM soft front panel offers the front-panel experience users expect from a traditional benchtop instrument.

Figure 3: NI’s DMM driver (NI-DMM) includes an interactive soft front panel for quick measurements and application debugging.

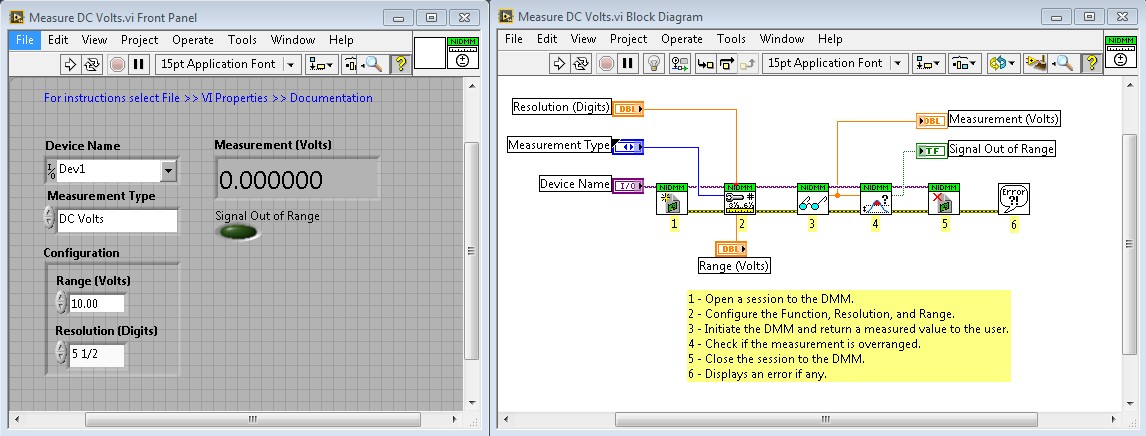

In addition to the soft front panel, the DMM driver includes a best-in-class API that works with a variety of development options such as LabVIEW, C, C#, and others. To ensure long-term interoperability of DMMs, the NI-DMM driver API is the same API used for all past and current NI DMMs. The driver also provides access to help files, documentation, and dozens of ready-to-run shipping examples you can use as a starting point for your application.

Figure 4: NI’s DMM driver (NI-DMM) includes dozens of ready-to-run shipping examples.

High-Precision DMM Measurements

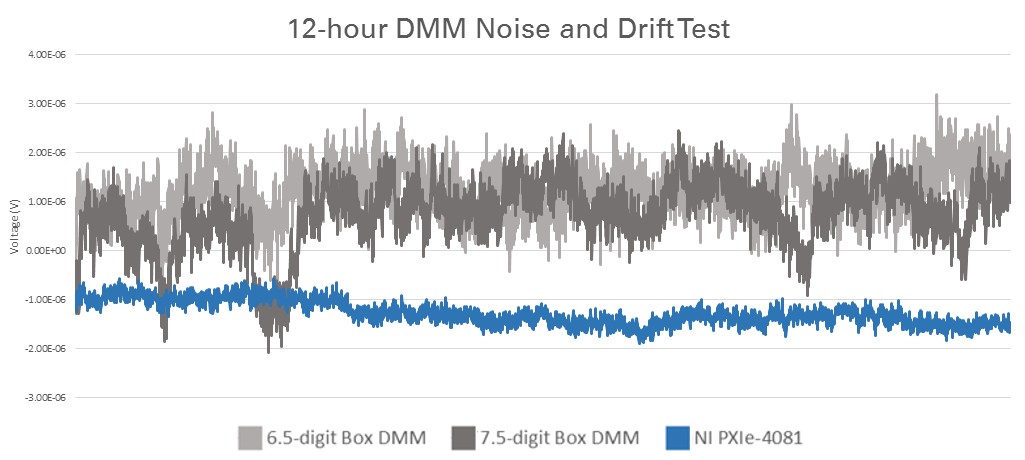

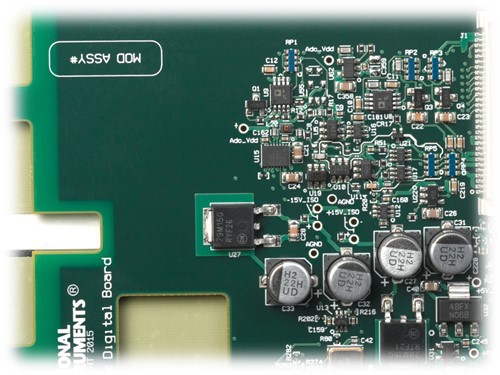

The analog-to-digital converter (ADC) is the backbone of high-performance PXIe-408x DMMs. A unique combination of off-the-shelf high-speed ADC technology and a custom-designed sigma-delta converter provides the noise, linearity, and speed performance required to achieve high-speed and high-precision measurements.

Figure 5: Over a 12-hour noise and drift test of 0 VDC with each DMM set to 100 mV input range with 10 PLC aperture time, the PXIe-4081(blue) outperforms both the leading 6½-digit (light grey) and 7½-digit (dark grey) benchtop DMMs.

The PXIe-4081 uses one of the most stable onboard voltage references available to provide stable performance across temperature and time. No other DMM in this price range offers this reference source and its accompanying stability, which is why the PXIe-4081 includes a two-year guaranteed accuracy of 12 ppm to further reduce the cost of test by minimizing downtime for instrument calibration. This beats the one-year accuracy specifications of most traditional benchtop DMMs, providing you more accurate measurements with lower cost of ownership and less downtime. The PXIe-4081 also uses advanced DMM measurement techniques such as offset compensated ohms, high-order DC noise rejection, and self-calibration to ensure accurate measurements.

Flexible Measurement Rate With an Isolated Digitizer

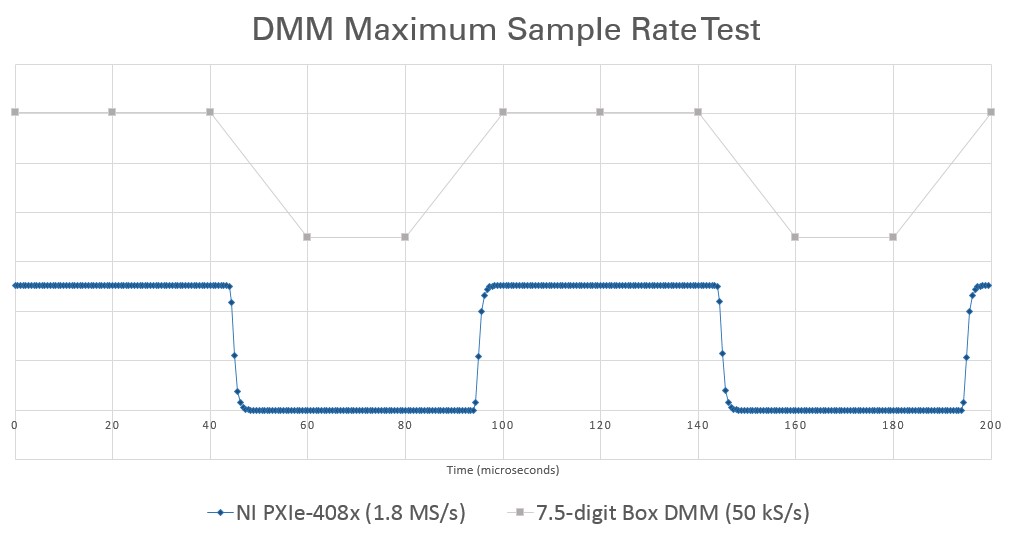

Traditional DMMs are designed to provide high resolution and precision, with little regard to acquisition speed. The unique architecture of the PXIe-408x DMMs offers a continuously variable reading rate that ranges from 7 S/s to 10 kS/s, so you can choose the sample rate and resolution you need for your application.

Figure 5: The unique combination of off-the-shelf high-speed ADC technology and a custom-designed sigma-delta converter (circuitry shown above) optimizes linearity and noise for up to 7½-digit precision and stability, while offering digitizer sample rates up to 1.8 MS/s.

Figure 6: PXIe-408x DMMs can acquire 36X faster than traditional benchtop DMMs, which gives you increased insight into your device under test.

Self-Calibration and 2-Year Guaranteed Specifications

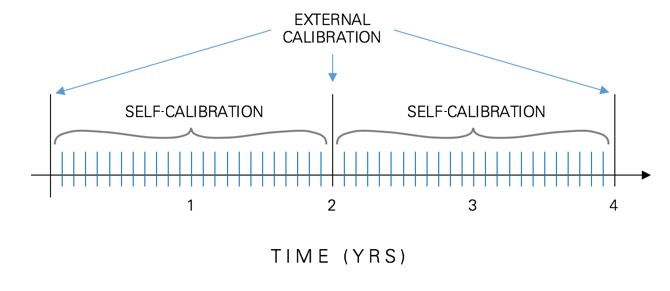

NI DMMs offer self-calibration, which is traditionally found in only the highest resolution DMMs. Self-calibration corrects for all DC gain and offset drifts within the DMM using a precision, high-stability internal voltage reference that has an outstanding temperature coefficient and time drift, accounting for all resistance and current source drifts. Using the self-calibration feature makes NI DMMs highly accurate and stable at any operating temperature—well outside the traditional 18 °C to 28 °C range.

Figure 7: Self-calibration further improve the measurement accuracy of NI PXI DMMs between the recommended 2-year external calibration cycle.

This operation takes less than a minute to complete and requires no external calibrator, minimizing the maintenance burden of deployed systems. PXIe-408x DMMs have a two-year external calibration cycle thanks to the self-calibration precision circuitry that minimizes the maintenance burden of deployed systems. Visit ni.com to learn more about NI’s calibration services.

Synchronization and Integration

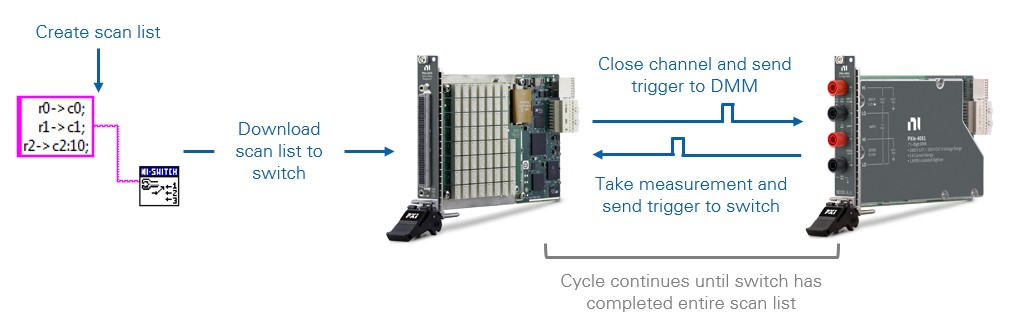

NI DMMs use the inherent timing and synchronization capabilities of the PXI platform to communicate with switches and other instruments within the PXI chassis. You can use switches with a DMM to expand the instrument’s measurement capability to hundreds or thousands of test points. NI DMMs “handshake” with NI switches by sending and receiving hardware-timed triggers over the PXI backplane, scanning through a list of switch connections stored in memory onboard the switch module. This method of scanning removes the software overhead associated with traditional scan lists and can create a deterministic scan list for faster test execution with more repeatable timing.

Figure 8: Achieve significantly faster test times by synchronizing NI DMMs with NI switches to create hardware-timed scan lists.

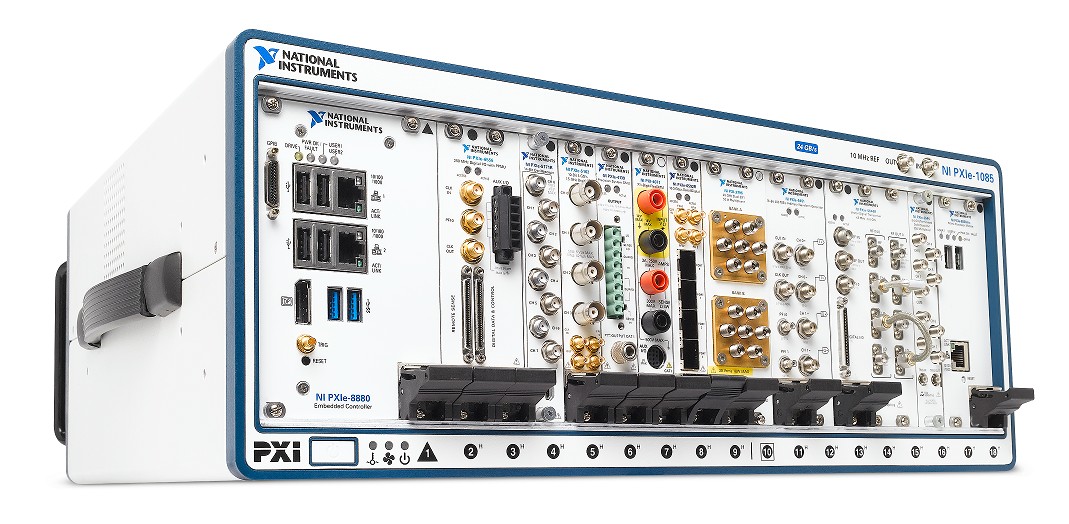

Additionally, the PXI platform includes instruments such as power supplies, oscilloscopes, and function generators that are commonly used with DMMs in automated test applications, so you can build tightly integrated systems in a compact form factor. In these situations, the DMM can also use the PXI backplane to send and receive triggers to synchronize its measurements with operations from other instruments without external cabling to route triggers.

Figure 9: The PXI platform provides excellent integration and synchronization with a variety of instruments like source measure units (SMUs), oscilloscopes, digital instruments, and RF signal analyzers and generators.

Build Your Next Test and Measurement System With NI DMMs

Used in applications ranging from semiconductor characterization to aerospace production test, NI DMMs combine high-performance measurement quality with industry-leading speed and comprehensive software support to help you develop smarter automated test and measurement systems. You can use PXI-based switches with NI DMMs to build high-channel-count acquisition systems and execute scan lists with hundreds or thousands of relay closures with deterministic hardware timing. The PXI platform also offers instruments such as SMUs, power supplies, oscilloscopes, waveform generators, and RF analyzers and generators that are not available on stand-alone benchtop DMMs. Built for automated test applications and ideal for your next test system, NI DMMs provide superior measurement quality compared with traditional DMMs.