Choosing the Right Industrial Digital I/O Module for Your Digital Output Sensor

Overview

Contents

- Introduction to Digital Output Sensors

- Classification of Digital Output Sensor Based on:

- Characteristic of the Signal Driving the Sensor Output

- Sinking vs. Sourcing Outputs

- 2-Wire and 3-Wire Sensors

- Electronic Component Used to Implement the Sensor’s Output

- Selecting the Right Industrial Digital I/O Module for Your Digital Output Sensors

- Example of Digital Output Sensors

Introduction to Digital Output Sensors

Digital Output Sensor is a sensor that will produce only two values in its output, either On or Off, as opposed to an Analog Output Sensor which produces a continuously varying output value over its entire range. The simplest example of a digital sensor is the touch switch. A typical touch switch is an open circuit with infinite resistance when it is not pressed and a short circuit with zero resistance when it is pressed.

Whenever interfacing the digital output sensor it is important to take into account some key factors that will determine the compatibility of the sensor with the data acquisition device. Throughout this document we will present these key factors and provide an easy way to select the appropriated data acquisition device for your application.

Classification of Digital Output Sensor Based on:

Digital Output Sensors can be classified based on the following parameters:

1. Characteristic of the Signal Driving the Sensor’s Output

2. Sinking vs. Sourcing Outputs

4. Electronic Component Used to Implement the Sensor’s Output

Characteristic of the Signal Driving the Sensor Output

Technological development has brought a variety of complex digital output sensors to the market. Nowadays, you can find sensors that produce trains of transitions between the On and Off state, with these types of sensors the frequency characteristic or even the shape of the pulse trains convey the sensor’s measurement, making it possible to implement continuous measurement.

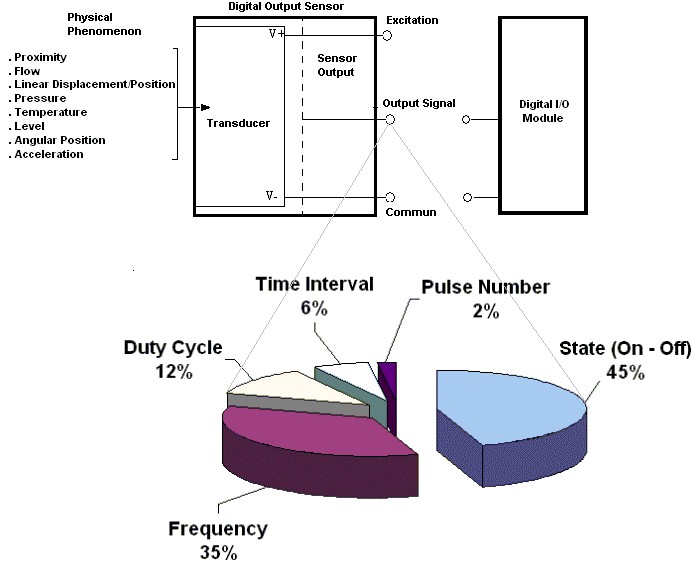

Figure 1 shows a classification of digital output sensors based on signal characteristics driving its output. As can be seen in the chart, 45 % of the digital output sensors are based on the on-off state of the digital line, 35 % of the sensors are based on the frequency of the signal and 12 % as based on the duty cycle of the output frequency 2.

Figure 1 – Digital Output Sensors – Characteristic Conveying Measurement2

The signal characteristic conveying the sensor’s measurement is the first parameter to be considered when selecting an industrial digital I/O module. This is important to decide whether you need counters on your digital I/O module.

Sinking vs. Sourcing Outputs

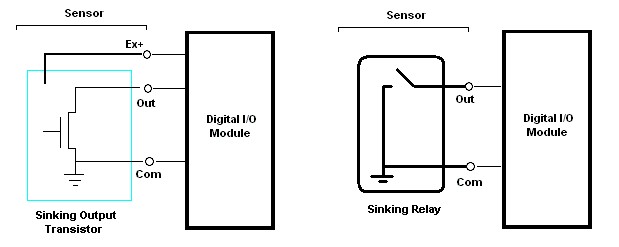

Sinking and Sourcing are terms used to define the control of direct current flow in a load.

- Sinking Device: provides a path for the current to ground and is not responsible for powering the device. Terms used to describe sinking devices include NPN, Open Collector, Normally High, and IEC Negative Logic.

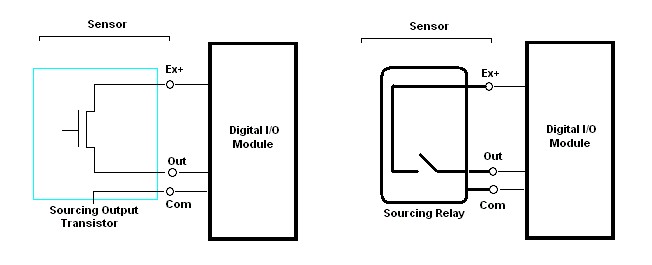

- Sourcing Device: A sourcing device provides the power or a positive potential. Sourcing devices 'push' the current through the load. Terms used to describe sourcing devices include PNP, Open Emitter, Normally Low, and IEC Positive Logic.

The concept of Sourcing and Sinking is independent of the component (ex.: transistor, mechanical relay and etc...) that implements the operation. This concept applies to any DC circuitry; the component that is implementing the circuitry may vary.

Figure 2 - Sinking Output Sensors.

Figure 3 - Sourcing Output Sensors.

2-Wire and 3-Wire Sensors

The third type classification is important in order to define the relationship between current and voltage in the sensor’s On state and Off state. A sensor can be classified as a 2-wire or 3-wire device as follows:

- 2-Wire Sensors: They are connected in series with the device that is acquiring the data.

When the sensor is not activated, it must draw a minimum operating current normally referred to as off-state leakage current, which in some cases are also called by the sensors manufacturers as residual current. This current is necessary in order to keep the sensor electronics working. The residual current is not a problem if the sensor is connected directly to another load other then the data acquisition device, for example in industrial environment is not unusual to have these 2-wire sensors directly connected to motors and similar devices, which have a low impedance.

Residual current is a problem for the system if the sensor requires a residual current higher then what the digital I/O module has been designed to sustain. In this case the digital I/O module might incorrectly detect an On state because the current being drawn is higher then it expects to provide. Most 2-wire sensors in the industry have an off-state leakage current or residual current no higher then 1.7 mA.

Similar to the Off state, there is also a minimum current required to sustain the On state of a sensor, called the minimum holding current. Typically this current ranges from 3 mA to 20 mA. The sensor will not operate correctly if the digital I/O module cannot sink or source this current.

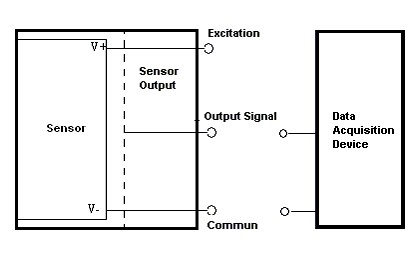

- 3-wire Sensors: 3-wire sensors derive their power from a excitation terminal and not directly through the digital output line, they are also called by some manufacturers as line-powered sensors.

Figure 5 – 3-wire Sensors

The operating current these devices pull from the digital I/O module is called burden current and it is typically in the neighborhood of 20 mA. Important to notice this current is provided by the excitation terminal.

Electronic Component Used to Implement the Sensor’s Output

There are three electronic components that typically drive the output of a signal output sensor:

- Mechanical Relay;

- Transistor;

- Bilateral FET Devices:

Mechanical Relay: A Mechanical relay is an electromechanical device that closes contacts to complete a circuit or opens contacts to interrupt a circuit. It is a device that can handle current load at high voltages.

Since they are relatively slow devices when compared against solid state relays, they are normally used by sensors where the state of the line is the characteristic of the signal driving output. These devices are subject to contact wear and resistance build up. Their contact life depends on the load current as well as the frequency of operation. They can sometimes produce erratic results due to contact bounce when connected to counters and digital I/O modules.

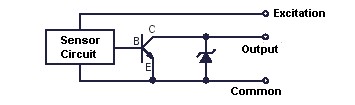

Transistor: is a solid-state device designed to control DC current. Transistors are most commonly found in low DC powered sensors as the output switch. There are two types of transistors - NPN and PNP.

Figure 6 shows a NPN (Current Sink) Open Collector Transistor

Figure 6 – Sensor NPN Output.

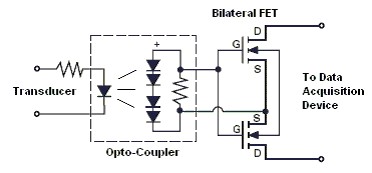

Bilateral FET Device: Many photosensors in the market have an output implemented in an architecture called bilateral FET output which can be seen in Figure 7. This architecture has many advantages but the most important one is the fact that interfaces directly to TTL and CMOS circuits, additionally they show:

- Low off-state leakage current;

- Fast response time;

FET stands for Field Effect Transistor and is supposed to become the most popular output for digital output sensors because of its operating characteristics, being near to the ideal model.

Figure 7 - Sensor with Bilateral FET Device Output

Selecting the Right Industrial Digital I/O Module for Your Digital Output Sensors

In order to select the Digital I/O module one should answer the three following questions:

- What is the characteristic of the digital signal that conveys the sensosurement? This has been discussed in the section on "Characteristic of the Signal Driving the Sensor’s Output" in this document.

Based on this answer make reference to Table-A to check the group of Digital I/O modules that would be appropriate for your application.

- Is the sensor output a sinking or sourcing output?

Table-A again provide a classification of the NI boards based on sinking and sourcing capabilities, so if your sensor has a sinking output you want to select a board with a sourcing input and vice-versa.

- What is the component that implements the output of my device?

At this point might need to consider the off-state leakage current as well as the minimum holding current for On state.

Compare specs of the sensors with the specs of the data acquisition devices in Table-B in order to select the most appropriate device for your sensor. Besides the voltage levels, one should still observe the two important following conditions which are sometimes overlooked:

1. Off-State leakage current (sensor) < Maximum Input Current at Low State (Board)

2. Minimum holding current (sensor) < Maximum Input Current at High State (Board)

| NI Board | On-Off (State) | Timed-Based Sensors (Frequency, Duty-Cycle, etc.) | Digital I/O Module Output Type | Type of Isolation | # Channels |

| NI 6601 | — | √ | Sinking | — | 4 CTR |

| NI 6602/6608 | — | √ | Sinking | — | 8 CTR |

| NI 6624 | — | √ | Sinking | Ch-Ch | 8 CTR |

| NI 6501 | √ | √* | Sinking/Sourcing | — | 24 DIO 1 CTR |

| NI 6509 | √ | — | Sinking/Sourcing | — | 96 DIO |

| NI 6514 | √ | — | Sourcing | Bank | 32 DI 32 DO |

| NI 6515 | √ | — | Sinking | Bank | 32 DI 32 DO |

| NI 6518 | √ | — | Sourcing | Bank | 16 DI 16 DO |

| NI 6519 | √ | — | Sinking | Bank | 16 DI 16 DO |

| NI 6520/6521 | √ | — | Sinking/Sourcing | Ch-Ch | 8 DI 8 DO |

| NI 6525 | √ | √* | Sinking/Sourcing | Ch-Ch | 8 DI 8 DO 1 CTR |

| NI 6528 | √ | — | Sinking/Sourcing | Ch-Ch | 24 DI 24 DO |

Table - A

| NI Board | Voltage Input | Current Input | Maximum Switching Capacity | ||||

| Input Logic Low Voltage (VIL) | Input Logic High Voltage (HIL) | Max Input Current (low) | Max Input Current (high) | ||||

| Min | Max | Min | Max | ||||

| NI 6601 | -0.3 VDC | 0.8 VDC | 2 VDC | Supply +0.3 VDC | -10 µA | 200 µA | 4 mA |

| NI 6602/6608 | -0.3 VDC | 0.8 VDC | 2 VDC | Supply +0.3 VDC | -10 µA | 200 µA | 4 mA |

| NI 6624 | — | 0.8 VDC | 3.2 VDC | 48 VDC | 0.1 mA | 10 mA | 200 mA |

| NI 6501 | -0.3 VDC | 0.8 VDC | 2 VDC | 5.8 VDC | — | — | ±8 mA |

| NI 6509 | 0 VDC | 0.8 VDC | 2 VDC | VCC | -91.0 µA | 91.0 µA | ±24 mA |

| NI 6514 | 0 VDC | ±4 VDC | ±11 VDC | ±30 VDC | 4.5 mA/line | 12.5 mA/line | 350 mA |

| NI 6515 | 0 VDC | ±4 VDC | ±11 VDC | ±30 VDC | 4.5 mA/line | 12.5 mA/line | 500 mA |

| NI 6518 | 0 VDC | ±4 VDC | ±11 VDC | ±30 VDC | 4.5 mA/line | 12.5 mA/line | 350 mA |

| NI 6519 | 0 VDC | ±4 VDC | ±11 VDC | ±30 VDC | 4.5 mA/line | 12.5 mA/line | 500 mA |

| NI 6520/6521 | 0 VDC | ±4 VDC | ±11 VDC | ±30 VDC | 4.5 mA/channel | 12.5 mA/channel | 2 A |

| NI 6525 | -60 VDC | 1 VDC | 3.2 VDC | 60 VDC | 3.0 mA/channel | 3.0 mA/channel | 500 mA |

| NI 6528 | -60 VDC | 1 VDC | 3.2 VDC | 60 VDC | 1.5 mA | 2 mA | 150 mA |

Table - B

Example of Digital Output Sensors

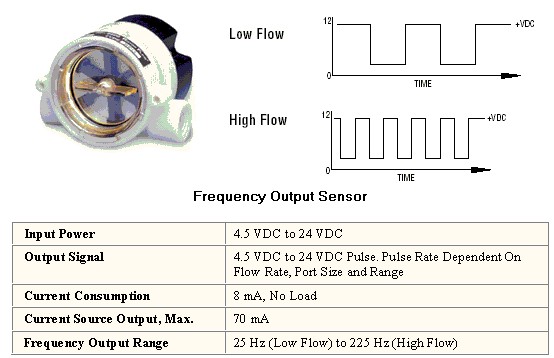

Type of Measurement: Flow Measurement

Manufacturer: Gems Sensors

Digital Output type: Frequency

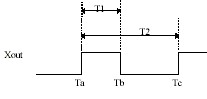

Type of Measurement: Acceleration (ADXL202, ±2 g Dual Axis Accelerometer)

Manufacturer: Analog Devices

Digital Output Type: Duty-Cycle (TTL, CMOS compatible)

Type of Measurement: Position Switch (Mechanical Relay)

Manufacturer: Schmersal

Digital Output Type: ON-OFF output.

Other Manufacturers of Digital Output Sensors include

· Omega

· Omron

· Encoder Products Co.

· US. Sensors

· Sensotec

· Watlow

· PCB Piezotronics

· Weed Instrument

· Measurement Specialities

· Celesco

· Endevco

· Macro Sensors

· Transducer Techniques Inc.

1 Throughout this document 'Digital I/O Module' is used to describe the data acquisition device that is connected to the Digital Output Sensor.

2 Kirianaki, Yurish, Shpak, Deynega. Data Acquisition and Signal Processing for Smart Sensors, 2002 [ISBN 0-470-84317-9].