What Are NI Vision Systems?

Overview

NI Vision systems consist of cameras for image acquisition and controllers for image processing and I/O operations. NI offers a variety of products you can use as controllers for vision systems. Each product provides unique features that make them suitable for different applications. Some of these differences include processing power, camera connectivity, and I/O options. This article provides an overview of these products and how you can use them in vision systems.

Contents

- NI Controllers You Can Use to Create a Vision System

- Considerations When Choosing a Vision System Controller

- Software Benefits With All NI Vision System Controllers

NI Controllers You Can Use to Create a Vision System

NI Industrial Controllers

NI industrial controllers are high-performance, fanless devices that offer the highest level of processing power and connectivity for automated image processing and control applications in extreme environments.

Figure 1. Industrial controllers from NI provide connectivity to GigE Vision and USB3 Vision cameras.

These controllers feature the latest Intel Core processors and Xilinx Kintex-7 FPGAs for FPGA image coprocessing, which makes them suitable for high-performance machine vision applications. Industrial controllers provide connectivity to GigE Vision and USB3 Vision cameras. They include DisplayPorts for a dual-monitor human machine interface (HMI), industrial communication ports, and industrial digital I/O that you can customize using the LabVIEW FPGA Module. Based on the GigE Vision standard, NI industrial controllers also include advanced synchronization features such as deterministic camera triggering over the Ethernet bus and queued pulse support for tightly synchronizing the vision inspection results with sorting and rejection systems using a simple API. With NI industrial controllers, you have the abundance of camera connectivity and processing power to solve vision applications where bandwidth and latency are key.

CompactRIO Controller

CompactRIO controllers use the latest Intel Atom processors and Xilinx Kintex-7 FPGAs. They offer connectivity to GigE Vision cameras and USB3 Vision cameras that are USB 2.0 backward compatible.

Figure 2. CompactRIO combines USB and Gigabit Ethernet camera connectivity with modular I/O.

The processor is used for network communication, data logging, control, and processing with the deterministic and reliable NI Linux Real-Time OS. The user-programmable FPGA can be used to implement custom hardware for high-speed control, inline data processing, or complex timing and triggering. Additionally, the FPGA can be used for FPGA image coprocessing, which reduces latency and processing time so cameras can be used as an input for closed-loop control applications. CompactRIO controllers also include slots for use with hundreds of C Series I/O modules, which allow for easy integration of I/O and sensor connectivity into the vision system.

Considerations When Choosing a Vision System Controller

Rugged Form Factor

NI industrial controllers and CompactRIO controllers, offer a fanless design, solid state hard drives, and extended temperature ranges, which makes them ready for the demanding conditions of manufacturing and embedded vision applications by reducing maintenance requirements and increasing reliability. The deterministic NI Linux Real-Time OS also adds to the operational reliability and makes systems exempt from the IT department updates and intervention that Windows-based systems experience.

Figure 3. NI Industrial Controllers, Compact Vision Systems (no longer sold), and CompactRIO controllers offer powerful processing in small, rugged packages.

In addition to ruggedness, size is often a main mechanical consideration for industrial and embedded vision applications. These products pack all of their features into small packages, which provides space savings in manufacturing and embedded systems.

Massive Software Ecosystem

NI industrial controllers and CompactRIO controllers are built on the LabVIEW reconfigurable I/O (RIO) architecture and programmed with the familiar LabVIEW development environment.

Figure 4. The LabVIEW RIO Architecture combines a real-time processor and FPGA to connect to sensors and I/O.

The NI Linux Real-Time OS helps developers innovate with the massive software ecosystem provided by the Linux community. Additionally, NI Linux Real-Time OS adds support for the Eclipse Development Environment, which gives you the freedom to reuse existing C/C++ code or development expertise. Now you can integrate code libraries into your LabVIEW Real-Time application, or even develop your own stand-alone executable interfacing directly to your LabVIEW FPGA application. You have the flexibility to develop using the tools that best suit your task and capabilities.

Camera Connectivity

You can use these systems with a wide variety of image sensor types, including infrared (thermal), line scan, color, area scan, and 3D laser triangulation.

The NI industrial controller has multicamera support with two dedicated USB 3.0 ports that can provide full USB SuperSpeed bandwidth to any USB3 Vision-compliant camera. NI industrial controllers and CompactRIO controllers have multicamera support.

The NI industrial controller and NI CVS-1459RT both have multicamera support with two dedicated USB 3.0 ports that can provide full USB SuperSpeed bandwidth to any USB3 Vision-compliant camera. NI industrial controllers, CompactRIO, and the NI CVS-1458RT have multicamera support with independent Gigabit Ethernet ports for use with any GigE Vision-compliant camera. With this camera connectivity, you can use a wide variety of image sensor types, including infrared (thermal), line scan, color, area scan, and 3D laser triangulation. NI industrial controllers and CompactRIO controllers feature GigE ports Power over Ethernet (PoE) technology, which reduces system complexity and cabling by powering cameras over the Ethernet bus.

Search the Camera Network to find a compatible camera.

Real-Time Display and HMI Compatibility

NI vision systems can output real-time images and pass/fail results from the inspection through the built-in VGA ports and DisplayPorts. You can change all of the user-definable image overlays programmatically to create custom user displays

Figure 5. Custom real-time deisplay on an HMI.

Also, a simple web browser on any Windows 7 or Windows Embedded 7 touch panel can act as an operator interface for selecting inspections, updating parameters, or training a new part. NI Vision software provides the ability to further program an HMI for Compact Vision Systems.

Industrial Communications and I/O Capabilities

NI industrial controllers Systems have 24 onboard reconfigurable digital I/O lines—eight 5-24 VDC isolated input lines, eight 5-24 VDC isolated output lines, eight bidirectional TTL lines, and two bidirectional differential RS422 lines that can be used as a quadrature encoder input. These lines include built-in functionality for generating strobe pulses, triggering, and writing/reading from digital lines. Using these signals, you can dynamically control your lighting or cameras, synchronize with a conveyor belt, or integrate Compact Vision Systems with programmable logic controllers (PLCs).

NI industrial controllers and CompactRIO controllers also support the Vision RIO API, which you can use to easily configure a queue or pulses. It provides a reliable, hardware-timed method of tightly synchronizing vision-inspection results with external I/O, such as conveyer belts and rejection systems.

In addition, the systems can send commands and data to other devices, including PLCs and operator interfaces, using industrial protocols such as Ethernet/IP, RS232/RS485, Modbus serial, and Modbus/TCP. With enterprise connectivity, you can also monitor the inspection results, view images, or store data in databases for statistical process control. These systems also have a dedicated Gigabit Ethernet port for network connectivity, a user-selectable RS232/RS485 serial port, and two high-speed USB ports for external data storage.

Software Benefits With All NI Vision System Controllers

Flexible I/O With LabVIEW FPGA

The digital I/O lines on NI industrial controllers and the C Series modules you use with your CompactRIO controller are directly connected. If your application requires specialized timing or custom I/O behavior, you can use LabVIEW FPGA to reconfigure the digital I/O lines to achieve additional functionality such as custom triggers, timing, PWM outputs, custom digital protocols, and high-speed counters.

LabVIEW FPGA extends the LabVIEW graphical development platform to FPGAs, which makes it simple to write your own I/O interfaces and data communication mechanisms in other low-level software tools and hardware description languages (HDLs). This gives you the ability to customize the FPGA on Compact Vision Systems more efficiently and effectively.

Imaging Software

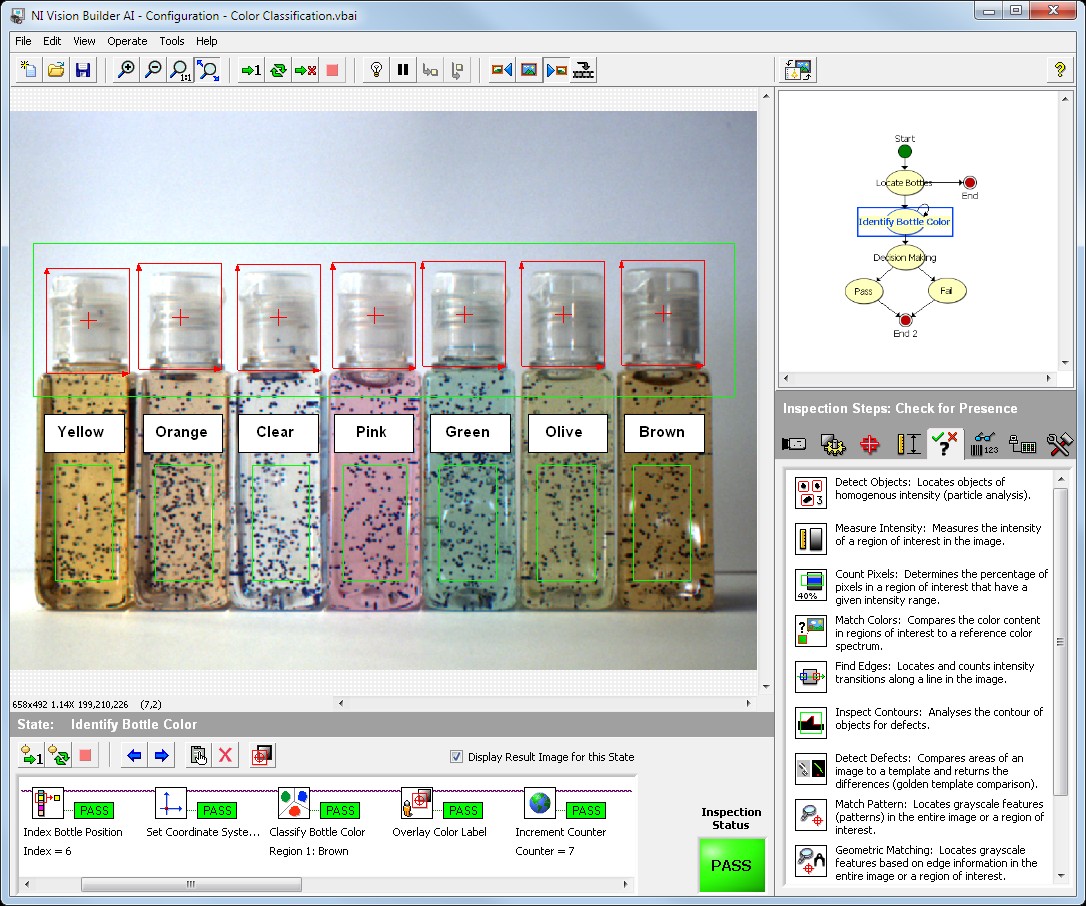

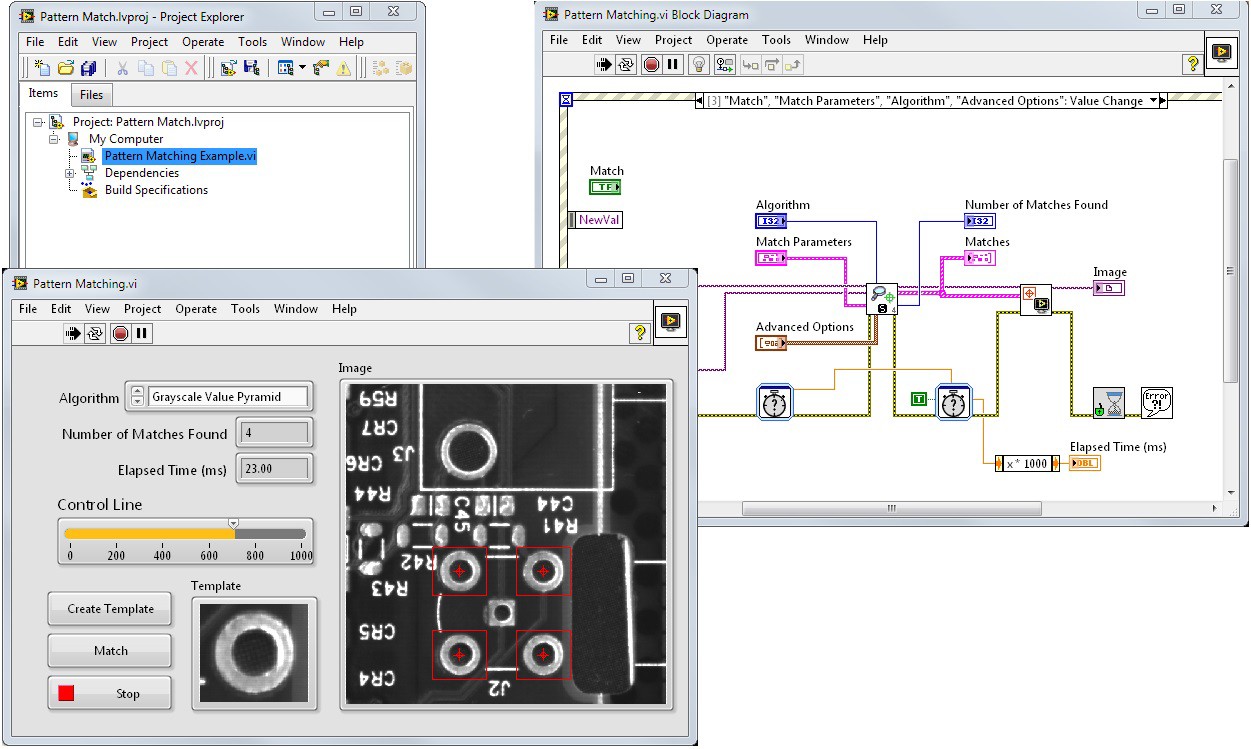

For nearly 20 to 30 years, NI Vision software has provided a comprehensive library of imaging functions to help you create a wide range of image acquisition and processing applications. You can program NI industrial controllers and Compact Vision Systems with either LabVIEW system design software using the Vision Development Module or with easy-to-use NI Vision Builder for Automated Inspection (Vision Builder AI). CompactRIO devices must be programmed using LabVIEW and the Vision Development Module because additional functionality is required to configure C Series I/O modules. Regardless, both LabVIEW and the Vision Development Module as well as Vision Builder AI help you achieve the following:

- Take advantage of hundreds of image processing algorithms

- Make decisions based on multiple inspection results

- View results through customizable deployment interfaces

- Communicate results using I/O and industrial communication protocols

Figure 6. (a) Vision Builder AI Configuration Interface

(b) LabVIEW Project Explorer, Front Panel, and Block Diagram for Vision Application

You can use LabVIEW and the Vision Development Module across the entire NI Vision hardware portfolio. So after learning just one set of vision software, you can easily reduce time and cost to maintain your systems or build new applications while enjoying the freedom to choose the suitable hardware for each application, be it an industrial controller, Compact Vision System, or CompactRIO controller. All NI Vision software comes with Vision Acquisition Software, a collection of drivers for IEEE 1394, GigE Vision, and USB3 Vision cameras that scales to support a larger range of camera types for use with other NI Vision hardware.

Figure 7. NI vision software works with all NI vision hardware.

Next Steps

- Shop NI Vision Systems

- Learn How to Choose the Best Controller for Your Vision System

- Evaluate and Learn More About NI Vision Software

The registered trademark Linux® is used pursuant to a sublicense from LMI, the exclusive licensee of Linus Torvalds, owner of the mark on a worldwide basis.